|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Image: Attention!)

With increasing stability and/or hardness of the rock and rolling speed of the disc cutters the temperature and wear of the single discs increases [Schad03]. |

|

(Image: Forces affecting the disc cutters ? single disc cutter with reference to [Schad03] [Image: S&P GmbH]) |

(Image: Forces affecting the disc cutters ? single disc cutter with reference to [Schad03] [Image: S&P GmbH]) |

Forces affecting the disc cutters - single disc … |

|

|

Centre cutters are excavation tools arranged in advance in the centre of the boring head in order to release the pressure in the centre of the working face during boring and especially in cohesive soils such as clay and silt with low to high plastic properties to counteract sticking of the boring head. |

|

|

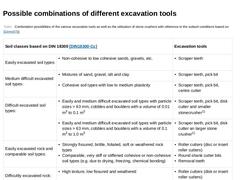

(Table: Combination possibilities of the various excavation tools as well as the utilization of stone crushers with reference to the subsoil conditions) |

|

|

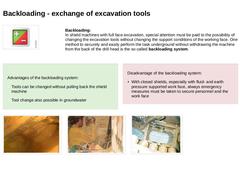

Backloading:

In shield machines with full face excavation, special attention must be paid to the possibility of changing the excavation tools without changing the support conditions of the working face. One method to securely and easily perform the task underground without withdrawing the machine from the back of the drill head is the so-called backloading system. Advantages of the backloading system: |

|

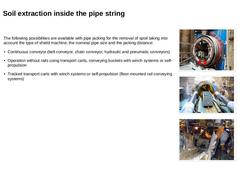

The following possibilities are available with pipe jacking for the removal of spoil taking into account the type of shield machine, the nominal pipe size and the jacking distance: -

Continuous conveyor (belt conveyor, chain conveyor, hydraulic and pneumatic conveyors)

-

Operation without rails using transport carts, conveying buckets with winch systems or self-propulsion

-

Tracked transport carts with winch systems or self-propulsion (floor-mounted …

|

|

|

|

|

Today, the installation of gas, water and wastewater pipelines is still predominantly carried out using open trenches. In view of the numerous disadvantages associated with this method, it is imperative that trenchless pipeline construction be considered much more strongly in the future than it has been to date as an alternative in the planning and construction of sewers and pipelines.

This module deals in detail with the procedure and the various components. Emphasis is placed on the different types of shield machines, excavation tools, separation systems, the control and steering station, injection/grouting agent and soil extraction and reprocessing.

After completing this module, you will have a sound knowledge of:

- all components of pipe jacking and

- their function and tasks.

|

|

| (Image: Presentation of a pipe jacking with an intermediate jacking station)

|

|

|

|

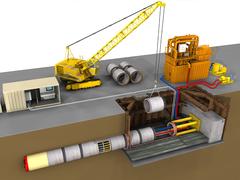

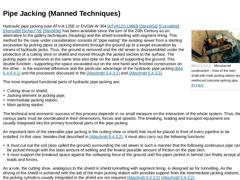

In this method, jacking pipes are jacked by pressing-in through the subsoil from a starting shaft to a target shaft with the aid of a jacking station as well as intermediate jacking stations.

Jacking in a straight or curved line path is made possible by means of a steerable shield machine positioned at the head of the first pipe. The spoil excavated at the working face is conveyed to the surface through the jacked pipe string. | |

|

|

| (Image: Attention!) With reference to the variant used to support the workface or to convey the excavated soil the technical components vary in pipe jacking. | | (Image: Schematic presentation of a pipe jacking) |

|

|

|

Advantages of trenchless technology compared to the open cut method: - Preventing break-up and replacement of road surface

- Prevention of soil excavation masses

- Minimizing groundwater retention measures

- Little impairment to traffic flow especially in inner urban areas

- Only short-term noise and emission pollution while excavating the starting and target shafts

| |

(Image: Disadvantages of the open cut method for installing drains and sewers (Part 1) [GSTT])

|

|

|

|

|

The duties of the shield machine in pipe jacking are

as follows [Scher77a] : - To protect the personnel,

- To create the necessary cavity so that the following pipe string can be pressed in with a minimum degree of soil deformation and with the lowest possible skin friction,

- To protect the cavity until the jacking pipes can finally carry all the loads and forces,

- To secure the working face against collapsing soil and rock as well as groundwater, and

…

|

|

|

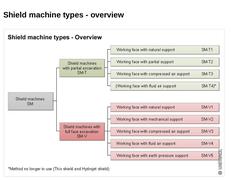

| (Image: Overview of shield machine types)

|

|

|

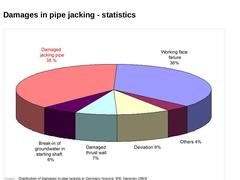

| In jacking processes, extensive and irreparable damages are frequently observed, which is due to irregularities of the subsoil. Although extensive subsoil investigations can reduce the subsoil risk, failures and damages cannot completely be excluded. | | (Image: Attention!) | These are the consequences of damages during pipe jacking: - Insufficient quality of the construction execution

- Delay

- High costs

- Environmental impacts

|

|

|

|

| (Image: Distribution of damages in pipe jacking in Germany (source: IFB, Hanover 1993))

|

|

|

|

|

(Image: Microtunnel construction - View of the start shaft with main jacking station and reinforced concrete jacking pipe [FI-FBS]) Hydraulic pipe jacking (see ATV-A 125E or DVGW-W 304 [ATVA125:1996]) [Stein85a] [Conra84b] [Hornu89] [Scher77b] [Stein85e] has been available since the turn of the 20th Century as an alternative to the gallery techniques (heading) and the shield tunnelling with segment lining. This method for the case under consideration … |

|

Today, supply and discharge lines are still predominantly installed by using the open-cut method: a trench is dug, the lines are installed. Under the protection of an embankment or sheeting and the trench is filled afterwards. In the face of the numerous disadvantages as well as the citizens' growing environmental consciousness in the future it is urgently necessary to take trenchless technology into account much stronger than until today as an alternative … |

|

|

(Image: Simple hand shield - working face with natural support) |

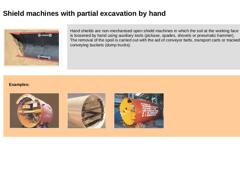

Hand shields are non-mechanised open shield machines in which the soil at the working face is loosened by hand using auxiliary tools (pickaxe, spades, shovels or pneumatic hammer). The removal of the spoil is carried out with the aid of conveyor belts, transport carts or tracked conveying buckets (dump trucks). |

|

|

|

Examples: |

(Image: Hand shield (external diameter 4672) with working … |

|

|