|

Masonry sewers with cement-bound joint mortar ( (Rubble, cut stone, masonry)) can show a number of defect types due to different causes. These types of defect include the partial or total loss of the joint mortar; bricks that are damaged, displaced or have fallen out of the bond; the breakdown of individual arch elements or the entire demolition of the constructional system (collapse). In EN 13508-2 [ [EN13508-2:2011]] this spectrum of defect types … |

|

Some examples for descriptions of defect of the main code “defective brickwork or masonry” are illustrated in Image 2‑49 to Image 2‑51. The characterisation is done in accordance with (Defective brickwork or masonry (BAD)). In EN 13508-2 [ [EN13508-2:2011]], it is recommended to quantify the description of defect “dropped invert” by stating the extent of displacement in mm (Image 2‑50) (Image 2‑51). The position of defect is to be recorded. (Table: … |

|

|

|

In addition to the types of defect described in (Defective brickwork or masonry (BAD)), for brickwork or masonry sewers, special attention is paid to the description of the defect classified as “missing mortar”. In EN 13508-2 [ [EN13508-2:2011]], that type of defect is defined as “all or part of the mortar from brickwork or masonry is missing”. A detailed characterisation inclusive of additional code specifications cannot be found in EN 13508-2 [ [… |

|

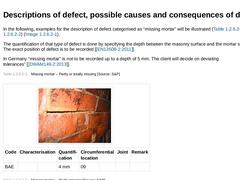

In the following, examples for the description of defect categorised as “missing mortar” will be illustrated (Image 2‑54) (Image 2‑55) (Image 2‑56). The quantification of that type of defect is done by specifying the depth between the masonry surface and the mortar surface in mm. The exact position of defect is to be recorded [ [EN13508-2:2011]]. In Germany “missing mortar” is not to be recorded up to a depth of 5 mm. The client will decide on deviating … |

|

|

|

In EN 13508-2 [ [EN13508-2:2011]] a “surface damage” includes occurrences of damaged interior surface areas of pipelines without liner caused by mechanical or chemical stress. The latter is also called internal corrosion. The main code “surface damage” explicitly includes the corrosion in metal pipes. According to EN 13508-2 [ [EN13508-2:2011]], surface damage is characterised by the type of damage and its cause – insofar as it is recognisable ( (… |

|

In the following, descriptions of defect under consideration of their cause will be introduced in accordance with EN 13508-2 [ [EN13508-2:2011]]. The description of defect categorised as “increased roughness” (A) means that the internal surface of the pipe does no longer have its original, smooth structure, but rather a roughened one. Possible causes of that development can be a chemical attack ( (Internal corrosion of cement-bound material)) or mechanical … |

|

According to EN 13508-2 [ [EN13508-2:2011]], and as already illustrated in (Surface damage (BAF)), in general, two causes are decisive for surface damage: -

Mechanical stress ( (Mechanical stress / mechanical wear))

-

Chemical attack (corrosion).

Not all of the pipe material that has been used in sewer systems in the past ( (Materials)) is equally prone to corrosion. In general, pipes made of vitrified clay are resistant to corrosion with the exception … |

|

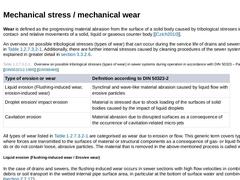

Wear is defined as the progressing material abrasion from the surface of a solid body caused by tribological stresses in the form of contact- and relative movements of a solid, liquid or gaseous counter body [ [Czich2010]]. An overview on possible tribological stresses (types of wear) that can occur during the service life of drains and sewers is illustrated in Table 2‑2. Additionally, there are further internal stresses caused by cleaning procedures … |

|

In the given case of application, internal corrosion is defined as the corrosion of the interior surfaces of drains and sewers. It can occur both partially (e.g. in the pipe joint area) and spread across sewer sections ( (Damage analysis)). For sewer systems, corrosion can be described as a reaction in sewer systems between a non-metallic or metallic construction material and its vicinity, which, due to chemical, electro-chemical or microbiological … |

|

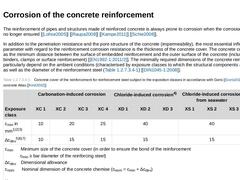

The reinforcement of pipes and structures made of reinforced concrete is always prone to corrosion when the corrosion protection is no longer ensured [ [Lohse2005]] [ [Raupa2008]] [ [Kampe2011]] [ [Schie2008]]. In addition to the penetration resistance and the pore structure of the concrete (impermeability), the most essential influential parameter with regard to the reinforcement corrosion resistance is the thickness of the concrete cover. The concrete … |

|

Internal corrosion of metal material Normally, unalloyed or lowly alloyed metal material for drain and sewer systems must be equipped with an internal and external corrosion protection. According to DIN EN 1123-1 [ [EN1123-1:2004]], pipes made of steel require a permanent internal and external corrosion protection in the form of hot galvanisation ( (Steel)). Additional protective layers are permissible, but must not impair the functional capability … |

|

|

|

Mechanical wear As already mentioned, the pipe material of surface water- and combined sewers is particularly prone to abrasion or erosion in the area of the wetted internal pipe surface due to mechanical wear. This results in the following consequences of damage [ [ATVM143-1:2004]]: -

Reduction of the wall thickness (change in the pipe-/structural statics and decrease of the leaktightness)

-

Increase of the wall roughness, reduction of the hydraulic …

|

|

In EN 13508-2 [ [EN13508-2:2011]] the external corrosion of drains, sewers and structures is not listed as a form of defect, as it cannot be recognised and recorded within the context of a visual internal inspection, but only by means of an external inspection or the extraction of samples from the inside. In contrast to these two sets of rules and regulations, DWA-M 149-2 [ [DWAM149-2:2013]] allows for a characterisation of the external corrosion … |

|

|

|

According to EN 13508-2 [ [EN13508-2:2011]], a connection is “general term used for the location at which one pipeline joins another pipeline or a manhole or inspection chamber”. The different connection types that have been carried out in practice so far can be found in (Laterals). As, according to EN 13508-2 [ [EN13508-2:2011]], both main codes “Intruding connection” and “Defective connection” are very similar in their damage causes and –consequences … |

|

Some examples for descriptions of defect classified into the main code “Intruding connection” and “Defective connection” along with the corresponding defect codings are illustrated in Image 2‑75 to Image 2‑79. (Table: Defective connection – Connection congested (Root ingrowth)) (Table: Defective connection – Pipe fracture in the connection area) (Table: Intruding connection) (Table: Intruding connection) (Table: Defective connection) Possible causes of … |

|

|

|

Since the beginnings of sewer system constructions, different types of sealing material have been used in order to align the constructions to the latest state of the art – sealing compounds, joint sealants, sealing rings etc. ( (Review)). In EN 13508-2 [ [EN13508-2:2011]], damage occurring in the context of sealing material is basically reduced to the category “Intruding sealing material” with the following definition: “All or part of the material … |

|

In the following, some examples for the description of defect “Intruding sealing material” are illustrated along with their respective coding (Image 2‑80 to Image 2‑84). According to EN 13508-2 [ [EN13508-2:2011]], the occurring forms of defect are only quantified in those cases where the sealing material is not a sealing ring. In these cases the reduction of the cross section is to be stated in per cent. The position of defect at the circumference … |

|

|

|

The main code “Displaced joint” is defined as the unintended deviation of the sewers from their planned and/or situationally determined target position during construction (positional deviation). In EN 13508-2 [ [EN13508-2:2011]], this type of damage is characterised as follows: “Adjacent pipes are displaced from their intended position in relation to each other.” According to EN 13508-2 [ [EN13508-2:2011]], the main code is characterised via the type … |

|

In addition to the characterisations of defect in accordance with EN 13508-2 [ [EN13508-2:2011]], ATV-DVWK-M 143-1 [ [ATVM143-1:2004]] lists the following descriptions of damage in that context: -

Deviations in line or level (lower arch / U-bend)

-

Lateral buckling

Deviations in line or level (U-bends) are composed of a series of several displacements at an angle. These displacements – as far as visible – are to be stated individually. In a first description, … |