|

Other findings include: -

Self-solidifying deposits consist of 90% mineral solids, which enter the sewer system through the street drains.

-

Of that about 30% are fine particles (≤ 0.1 mm) which contribute to the formation of hard to loosen, cohesive and pasty deposits.

Note:

Along with the fine mineral particles, fine organic particles also form part of the deposit structure, and can sometimes act as a concrete like binder between the mineral particles. |

|

Deposits have a number of negative consequences on the operation of drainage networks, all of which are also associated with economic disadvantages. They also contribute to water pollution. Impact of the deposits on the operation of the sewer systems are: |

|

Congratulations! You have successfully finished this module. Next you will have the opportunity to review the newly acquired knowledge with an interactive questionnaire. You can of course still navigate back to any point in the modules if you wish to review a specific point or subject. Stay curious! |

|

|

|

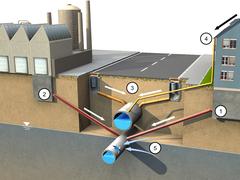

Drain and sewer may only be used in such a way that any avoidable impairment of groundwater and water bodies is eliminated. The solid’s physical properties and the sewer system’s hydraulic condition dictate whether they will reach the sewer treatment facilities or be deposited in the sewer line. The latter is the subject of this module. After completing this module, you will have a sound knowledge of: - the origin of solids and their transport characteristics;

- the consequences of solids discharge for the operation and maintenance of drain and sewer systems.

|

|

(Image: Picto Cleaning) -

According to [EN752:2008] cleaning is one of the most important measures for maintaining and ensuring a long-lasting efficiency of drain and sewer systems.

-

Both management and monitoring of cleaning measures for drains and sewers is specified in the German national standard [EN14654-1:2005] and North American standards [AWWA G520-17 ] [ASCE 2019]

|

|

(Image: Picto Recht Standards Law ) The following is a summary of essential standards that apply to the planning and execution of cleaning measures: -

DIN 14654-1: Management and monitoring of cleaning measures for drainage canals and sewers – Part 1: Cleaning of canals

-

DWA-A 147: Drainage system operating expenses – Operating tasks and frequencies

-

DWA-M 174: Drainage system operating expenses – Information about personnel, vehicles and equipment …

|

|

For the implementation of sewer cleaning, there are no technical guidelines that give the client and operator information regarding the required cleaning cycle, which price-performance-ratio is justified, or which procedure or equipment is best suited to a particular situation. Cleaning interval frequency depends on a large number of parameters such as: -

Type of drainage process,

-

Gradient and discharge conditions,

-

Type of deposit and agglomeration, …

|

|

(Image: Picto Proactive Reactive) Cleaning measures can either be implemented proactively or reactively. (Image: Reactive cleaning - Considerable deposits which are partly already solidified - Considerable restriction of the hydraulic performance and very costly cleaning) (Image: Reactive cleaning - Considerable deposits that have already solidified - Hydraulic efficiency no longer given and cleaning no longer possible, at most by use of milling and … |

|

(Image: Picto Proactive) Proactive cleaning as per DIN 14654-1 serves to mitigate problems before they occur by implementing the following principal objectives: -

Securing a defined status (safe and correct operation) of drains and sewers by eliminating debris, deposits, obstacles, etc.;

-

Preventing the appearance of odours and gases caused by putrefaction processes as well as the formation of biogenic sulphuric acid corrosion in structures made of …

|

|

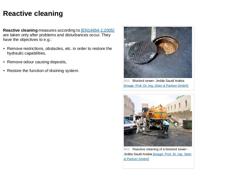

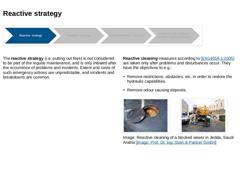

(Image: Picto Reactive) Reactive cleaning measures according to [EN14654-1:2005] are taken only after problems and disturbances occur. They have the objectives to e.g.: -

Remove restrictions, obstacles, etc. in order to restore the hydraulic capabilities,

-

Remove odour causing deposits,

-

Restore the function of draining system.

(Image: Blocked sewer- Jedda Saudi Arabia) (Image: Reactive cleaning of a blocked sewer - Jedda Saudi Arabia) |

|

|

|

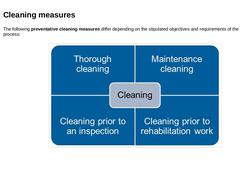

The following preventative cleaning measures differ depending on the stipulated objectives and requirements of the cleaning process: (Image: Cleaning measures) |

|

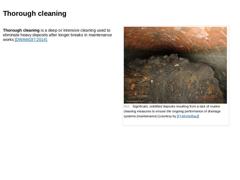

Thorough cleaning is a deep or intensive cleaning used to eliminate heavy deposits after longer breaks in maintenance works [DWAM197:2014]. (Image: Construction debris in a large profile sewer) |

|

Maintenance cleaning is the typical case for the cleaning of drain and sewer systems. Its cleaning objectives include the removal of foreign deposits, restoration of the hydraulic performance, limitation of putrefaction odours, limitation of polluting discharges in receiving waters, and the elimination, or at least reduction, of biogenic sulphuric acid corrosion of cementitious structures. Maintenance cleaning is usually limited to the sewer invert … |

|

-

Cleaning prior to an inspection is a special cleaning method focusing on the entire cross section of the sewer in order to expose any visible structural damage so that it can be quantified.

-

Cleaning prior to rehabilitation works is also a special cleaning method. The requirements to be met depend on the specifications of the planned rehabilitation project, and may extend from a basic cleaning up to a specialised treatment of the inner surface of …

|

|

|

|

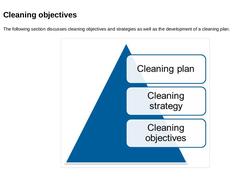

The following section discusses cleaning objectives and strategies as well as the development of a cleaning plan. (Image: Cleaning objectives and strategies) |

|

In addition to the previously mentioned principal objectives, the development of the cleaning plan may include further objectives, as e.g.: -

Reduction of operating costs;

-

Minimisation of public disturbance and citizen complaints;

-

Compliance with technical and legal requirements;

-

Improved quality control and documentation of cleaning works by the staff/service providers;

-

Acquisition of information for future cleaning planning.

|

|

A specification of the principal objectives for individual network sections is realised through following performance requirements and measurable cleaning objectives outlined in [EN14654-1:2005] and [ASCE 2019]: -

Restoration of the flow capacity to the nominal design value;

-

Removal of deposits and debris up to a prescribed level;

-

Limitation of the build-up of sediments to prescribed levels;

-

Limitation of the deposits to existing levels (maintaining …

|

|

The cleaning plan will be derived from the cleaning objectives and the chosen cleaning strategy. Important: The cleaning strategy describes a long-term oriented systematic approach to achieve defined cleaning objectives considering the individual network situation, available operational experience, means and resources [Baren2005] [NRW1995]. |

|

|

|

(Image: Arrow Reactive preventive strategy) Two cleaning strategies that are often applied, normally in combination, are: However, those two strategies are not contemporary anymore and should be substituted by In the following, all four strategies are introduced. [Haußm98a] |

|

(Image: Arrow Reactive strategy) The reactive strategy (i.e. putting out fires) is not considered to be part of the regular maintenance, and is only initiated after the occurrence of problems and incidents. Extent and costs of such emergency actions are unpredictable, and incidents and breakdowns are common. Reactive cleaning measures according to [EN14654-1:2005] are taken only after problems and disturbances occur. They have the objectives to e.… |

|

(Image: Arrow Preventive strategy) The preventive strategy is based on maintenance cleaning and is carried out in fixed and systematic intervals. (Image: High-pressure cleaning as part of a routine maintenance operation) (Image: Back up flushing as part of a routine maintenance operation) (Image: Surge flushing as part of a routine maintenance operation) |