|

The CCTV camera system consists of a video camera that is attached to the end of a telescopic rod which also has a lamp used for the illumination of the section to be inspected. The telescopic rod can be extended up to a length of 12 m. Through the use its optical zoom and additional lighting, the camera is capable of identifying problems (such as blockages, roots and debris etc.) up to 30 m beyond that of a regular visual inspection. |

|

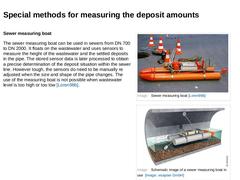

Sewer measuring boat The sewer measuring boat can be used in sewers from DN 700 to DN 2000. It floats on the wastewater and uses sensors to measure the height of the wastewater and the settled deposits in the pipe. The stored sensor data is later processed to obtain a precise determination of the deposit situation within the sewer line. However tough, the sensors do need to be manually re adjusted when the size and shape of the pipe changes. The … |

|

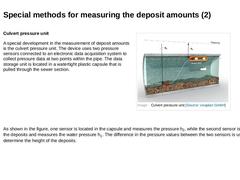

Culvert pressure unit A special development in the measurement of deposit amounts is the culvert pressure unit. The device uses two pressure sensors connected to an electronic data acquisition system to collect pressure data at two points within the pipe. The data storage unit is located in a watertight plastic capsule that is pulled through the sewer section. (Image: Culvert pressure unit) As shown in the figure, one sensor is located in the capsule … |

|

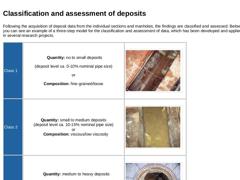

Following the acquisition of deposit data from the individual sections and manholes, the findings are classified and assessed. Below you can see an example of a three-step model for the classification and assessment of data, which has been developed and applied in several research projects. |

Class 1 |

Quantity: no to small deposits (deposit level ca. 0-10% nominal pipe size) or Composition: fine-grained/loose |

(Image: Klassifizierung und Bewertung … |

|

|

(Image: Haltung) Important: The section with the highest problem level should be decisive for the determination of a cleaning priority. In the process of prioritisation the deposit quantity and its composition can both be used as equal assessment criteria. |

|

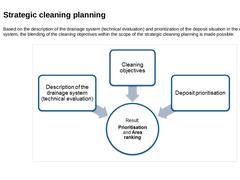

Based on the description of the drainage system (technical evaluation) and prioritization of the deposit situation in the drainage system, the blending of the cleaning objectives within the scope of the strategic cleaning planning is made possible. |

(Image: Strategic cleaning planning) |

|

|

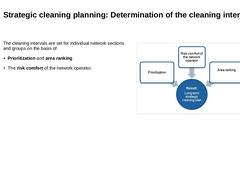

The results show a prioritisation and area ranking which in addition to a technical assessment of the deposits also include environmentally related, operational, hydraulic, economic and other strategic aspects, such as the sensitivity of surrounding structures (hospital, industrial enterprise, etc.). (Image: District ranking) |

|

The cleaning intervals are set for individual network sections and groups on the basis of (Image: Determination of the cleaning intervals) |

|

The Result is a long term strategic cleaning plan that is continually updated based on new operating experience and information |

(Image: Strategic cleaning planning) |

It is highly recommended to increase the cleaning intervals only gradually to minimise the impact of any forecasting inaccuracies. |

|

The cleaning measures are carried out based on operative cleaning planning in the form of operational or flushing plans. These plans include: a priority ranking of the determined cleaning measures, specifying both the cleaning method of choice and associated cleaning devices and tools |

|

The operational or flushing plan describes when, where and how to clean. "When" and "where" are mostly based on the strategic cleaning plan. The "How", i.e. which method and process parameters are to be chosen for cleaning, requires exact knowledge of the local circumstances. |

When? |

Where? |

How? |

|

(Image: Picto Uhr Clock) |

(Image: Where - Operative cleaning planning) |

(Image: Overview of the drain and sewer cleaning methods as per [Führb1980]) |

|

|

In accordance with DIN EN 14654, the following information is to be taken into consideration: -

Composition and extent of the deposits and agglomerations to be removed

-

Nominal size, length and depth of the drain or sewer

-

Material of the drain or sewer and its susceptibility towards damage caused in the cleaning process

-

Structural condition of the drain or sewer and its susceptibility towards a change for the worse due to damage caused in the cleaning …

|

|

-

Hazard sources (e.g. discharge of industrial sewage)

-

Distance between the shaft or inspection chamber and the most remote spot to be cleaned

-

Limitations in the accessibility of the manhole/shaft constructions or inspection chambers (e.g. traffic situation, surrounding structures, etc.)

-

Limitations in the accessibility of the manhole/shaft constructions or inspection chambers with respect to structural conditions (nominal size, etc.)

-

Necessity …

|

|

-

Possibility of access via the shaft or inspection chamber to the most remote spot to be cleaned through a section that is straight, curved, or equipped with fittings

-

Possibility of sewage retention and overflow or limitations due to short-term backed-up sewage

-

Environmental criteria, such as noise, odours, etc.

[ [EN14654-1:2005]] |

|

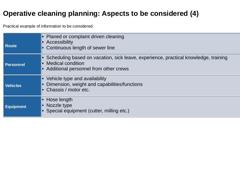

Practical example of information to be considered. |

Route |

|

|

Personnel |

-

Scheduling based on vacation, sick leave, experience, practical knowledge, training

-

Medical condition

-

Additional personnel from other crews

|

|

Vehicles |

|

|

Equipment |

-

Hose length

-

Nozzle type

-

…

|

|

|

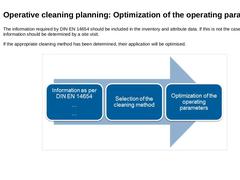

The information required by EN 14654 should be included in the inventory and attribute data. If this is not the case, the missing information should be determined by a site visit. If the appropriate cleaning method has been determined, their application will be optimised. (Image: Optimization operating parameters) |

|

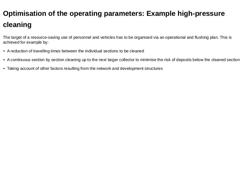

The target of a resource-saving use of personnel and vehicles has to be organised via an operational and flushing plan. This is achieved for example by: -

A reduction of travelling times between the individual sections to be cleaned

-

A continuous section by section cleaning up to the next larger collector to minimise the risk of deposits below the cleaned section

-

Taking account of other factors resulting from the network and development structures…

|

|

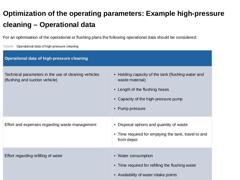

For an optimisation of the operational or flushing plans the following operational data should be considered: (Table: Operational data of high-pressure cleaning) |

|

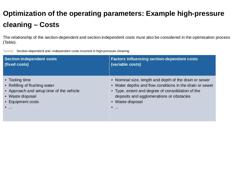

The relationship of the section-dependent and section-independent costs must also be considered in the optimisation process (Table). (Table: Section-dependent and -independent costs incurred in high-pressure cleaning) |

|

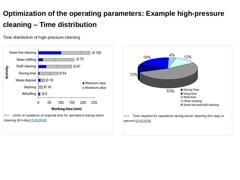

Time distribution of high-pressure cleaning (Image: Limits of variations of required time for operations during sewer cleaning (8-h-day)) (Image: Time required for operations during sewer cleaning (8-h-day) in percent) |

|

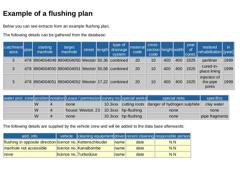

Below you can see extracts from an example flushing plan. The following details can be gathered from the database:

catchment

area |

plan |

starting manhole |

target manhole |

street |

length |

type of drainage system |

material code |

cross-section code |

height |

width |

year of const. |

realised rehabilitation |

in [year] |

|

3 |

478 |

8904004049 |

8904004050 |

Weststr |

50,36 |

combined |

20 |

10 |

400 |

400 |

1925 |

partliner |

1999 |

|

3 |

478 |

8904004050 |

8904004051 |

Weststr |

|

|

(Image: Arrow Step 03) In step 3, the cleaning planning is implemented based on the developed operational and flushing plans. |

|

During cleaning, the collected waste is to be checked as regularly as possible. A higher proportion of mineral solids and broken pipe bits indicates serious damage, e.g. pipe fracture or collapse. In such situations, the cleaning procedures have to be stopped immediately and protective measures have to be taken. If required, a less destructive cleaning method is to be chosen before cleaning is continued. (Image: Look at the waste material) |

|

Disposal of the collected waste material. |

(Image: Stockpiling of the solid waste material at the service depot) |

(Image: Disposal of the liquid waste material directly into the sewage treatment plants feeder line) |

|

|

Since June 1, 2005, the dumping of biodegradable waste - including the waste material from sewer cleaning procedures - without a prior thermal or appropriate mechanical-biological treatment is only permitted, insofar as the organic portion of the dry residue (measured as loss due to heating) does not exceed the values given: -

3 % by weight: Geological barrier, Landfill class 0 and I

-

5 % by weight: Landfill class II

-

10 % by weight: Landfill class …

|