|

Measures for the restoration of defective regions in the inside of sewers of concrete, reinforced concrete and pre-stressed concrete have the aim, depending on the selected repair grout, among others of [DAfStBb] : - The maintaining and replacement of the corrosion protection of the reinforcement;

- Replacing / supplementing the concrete cross section with or without requirements of stability;

- Replacing or increasing the resistance of the concrete surface …

|

|

Although sewer clinkers in masonry sewers are generally resistant to acids (for exceptions (Abschnitt 2.6.4), the cement-bound grout joints are destroyed with corresponding loading (Abschnitt 2.6.4). If these masonry joints are not filled in with an appropriate grout again (pointing), then the result can be leaks, the falling out of one or more sewer bricks from the walls up to collapse of the arching. In this type of damage in the wetted cross section, … |

|

Processes have been developed especially for the cases where the static bearing strength of individual pipes is endangered, that permit these to be secured for a certain period of time and thus to delay the time of replacement or for a time until the start of other, more comprehensive measures of damage elimination. The steel tension rings for man-accessible sewers belong to these processes. In this process, and depending on the type of damage and … |

|

The core of this robot system is a self-propelled carrier apparatus that can be equipped with milling, drilling and injection heads, a trowel arrangement or shell with grout supply (Bild 5.2.1.6.1). |

(Image: KA-TE milling and trowel robots [FI-Kunsta]) |

(Image: Application possibilities of the KA-TE system for repairs in the non-man-accessible region [FI-Kunsta]) |

The system is suitable for carrying out repairs in concrete and reinforced concrete, … |

|

(Image: SikaRobot system [FI-Sika] - Lowering the Sika robot into the manhole) The SikaRobot system [FI-Sika] consists of three hinged-together machine units for ease of introduction into the sewers via a manhole (Bild 5.2.1.6.2) (Bild 5.2.1.6.2) (Bild 5.2.1.6.2) (Bild 5.2.1.6.2). In the base version it consists of a drive unit, a control unit and a working head with tool holders as well as a TV camera for visual control of the repair works. The applicability … |

|

Remote controlled robot processes are available for eliminating points of damage such as leaks, flow obstacles, cracks, pipe breaks and projecting or unprofessionally installed nozzles in non-man-accessible sewers. The following are some of the commercially available robot processes: - KA-TE (Abschnitt 5.2.1.6.1) [FI-Kanal] [FI-Kunsta]

- SikaRobot (Abschnitt 5.2.1.6.2) [FI-Sika]

- kanaltec EL 300/EL 600 [FI-KU]

- KASRO [FI-DTI]

- PEKA-Tech [FI-KRT]

- ROBBY TECH […

|

|

Restoration processes are used for local or sectional rectifications or for the replacement of pipes or structural components in order to restore the functionality, the static load bearing capacity as well as the leaktightness. |

|

The choice of the injection processes and the execution of the injections are dependent, among others, on the prevailing geological and hydro-geological conditions, the condition and the depth of the sewer as well as the purpose of the injection. Thus, the possibility of a pre-injection in strongly porous layers of the affected sewer sector, as well as an after-pressing, can be important. As regards the injection technology, numerous processes are … |

|

The aims of injection from outside are to fix and/or seal the defective piping region of surrounding unconsolidated soils and thus to restore the lost functions of this sewer sector, or to fill the available cavities. The regions to be injected are made accessible from the ground by means of drilling, pressing lances or similar and injected under pressure with a suitable injection medium. The main areas of use are non-man-accessible sewers situated … |

|

In the region of leaks or assumed cavities, holes are drilled in the sewer or structure walls and either injection lances or nozzles are inserted through which injection medium is pressed in [Under85] (Bild 5.2.2.3.1) (Bild 5.2.2.3.1). |

(Image: Mixing pipe attached to a brickwork packer)

|

(Image: Circumferential injection of the embedment of an ovoid profile with cement suspension [FI-KMG])

|

In the presence of typical longitudinal cracks (Abschnitt … |

|

The filling, e.g. the injection and soaking of cracks in man-accessible sewers and structures of drain and sewer systems extends exclusively to the materials of concrete, reinforced concrete or brick masonry because of the large nominal sizes. There are no special technical regulations for the injection of cracks in the application cases mentioned above. Basically, the guidelines of the Deutsches Betonverein [NN81] as well as the "Zusätzlichen Technischen … |

|

The injection of pipe joints in man-accessible cross sections can be carried out in a similar manner to that mentioned for the injection of cracks or with the use of special packers.

These packers are positioned by hand or by machine at the leaking pipe joint.

The individual working steps in the application of the USA patented three-part packer (US Patent No.3,951,173) as shown in the video. (Video: Sketch showing principle of sealing pipe joints with … |

|

With injection from inside, and depending on the process and media utilised, all the aims of the injection processes mentioned in Abschnitt 5.2.2 can be achieved in man-accessible as well as in non-man-accessible regions. Injection from inside offers the following advantages over that from outside: - Less disturbance of traffic;

- No damage to walkways or traffic lanes;

- Less danger to other supply and drain pipes;

- More accurate acquisition and injection …

|

|

(Image: Schematic depiction of the Posatryn process) The Posatryn process is based on the Penetryn process (Patent No. 3,168,908/3,168,909) and was developed in the USA in the year 1960 and has been used in the Federal Republic of Germany since 1975 [NASSCO85a] [Rhode66] [Schop81]. In the region of the respective point of damage a packer is positioned under supervision using a TV camera and this makes the injection possible (Bild 5.2.2.4.1.1.1.1). |

|

The Posatryn process is meant mainly for sealing pipe joints and lateral cracks, as well as locally limited leaks in pipes with a circular cross section in all materials usually used in the sewage sector in the nominal size range of DN 150 to DN 4500 with the exception of masonry sewers. Corresponding packers are also available for ovoid cross sections 200/350. Other cross sectional forms require special equipment. The preferred regions of application … |

|

The preparations include the cleaning of the respective section of the sewer and the removal of any existing flow obstacles that can hinder the pulling of the packer through the section of the sewer to be repaired. When using a packer with a centrally arranged throughflow, the volume flow of the sewer can be maintained by up to 50 % of its capacity as long as it does not cause a back up. |

|

The individual working steps of the Posatryn process are shown in the video.

The apparatus required - sewer TV camera and packers (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) (Bild 5.2.2.4.1.1.1.4) - are introduced into the section of the sewer through the manhole and pulled to the point of damage and positioned there by a winch by remote control.

The packer |

|

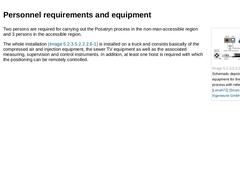

(Image: Schematic depiction of the equipment for the Posatryn process with reference to [Lenah72] [Image: S&P GmbH]) Two persons are required for carrying out the Posatryn process in the non-man-accessible region and 3 persons in the accessible region. The whole installation (Bild 5.2.2.4.1.1.1.5) is installed on a truck and consists basically of the compressed air and injection equipment, the sewer TV equipment as well as the associated measuring, … |

|

The Posatryn process offers the following advantages: - No structures or excavations are required;

- The flow can be maintained up a maximum of 50 %;

- Up to 150 m of sewer length can be rehabilitated from one position;

- Can be used for all pipe materials and for circular, ovoid and special cross sections;

- Can be used in the nominal size region of DN 150 to DN 4500;

- Economical due to being applied only to leaking regions;

- High capacity with little personnel …

|

|

|

|

|

(Image: Inflated packer of the Seal –i-Tryn process for DN 600 [FI-IBAK])

|

|

(Image: Principles of the function of the high pressure mixing head)

|

For this process, which is similar in principle to the Posatryn process, a new packer has been developed [FI-IBAK]. It consists of a hollow aluminium cylinder over which is pulled a one-piece, highly elastic and wear-resistant sleeve with two integrated inflatable chambers (Bild 5.2.2.4.1.1.2). By means … |

|

|

(Image: 3-Part Telespector packer (BCS System AG; Telespector)) |

|

|

The Telegrout system was developed in the USA by the Haliburton Company [Claph65]. This system utilises a 3-part packer (Bild 5.2.2.4.1.1.3) that can be used in three variants in the nominal size range of 150 mm to 700 mm.

|

|

As representatives for this process group, the Posatryn (Abschnitt 5.2.2.4.1.1.1), Seal-i-Tryn (Abschnitt 5.2.2.4.1.1.2) and the Telegrout systems (Abschnitt 5.2.2.4.1.1.3) will be dealt with in more detail in the following. |

|

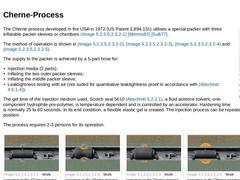

(Image: Cherne process - 3-Chamber packer [FI-Schei]) The Cherne process developed in the USA in 1972 (US Patent 3,894,131) utilises a special packer with three inflatable packer sleeves or chambers (Bild 5.2.2.4.1.2.1) [Mimms83] [Sulli77]. The method of operation is shown in Bild 5.2.2.4.1.2.1, Bild 5.2.2.4.1.2.1, Bild 5.2.2.4.1.2.1 and Bild 5.2.2.4.1.2.1. The supply to the packer is achieved by a 5-part hose for: - Injection media (2 parts);

- Inflating …

|

|

The packer system for the injection and the working steps of the MUSA process correspond to those of the Cherne process. In addition, a test chamber is added at the front in order to prove the required socket leaktightness and a rotating high pressure cleaning for flushing of contaminants in the gap of the pipe joint as a preparatory measure (Bild 5.2.2.4.1.2.2) (Bild 5.2.2.4.1.2.2) (Bild 5.2.2.4.1.2.2) [FI-maagh]. |

(Image: MUSA process: Sketch of … |

|