|

Trenchless construction technique:

Any technique for constructing pipelines in the ground without opening trenches [DINEN12889:2000]. |

|

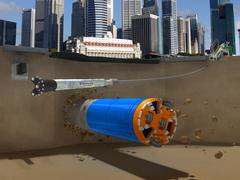

(Image: Shield machine arriving in the target shaft) |

|

(Image: Microtunnelling machine with pneumatic spoil removal (method AVP [FI-Herreb]) - Scraper cutting head with view of the rotary vane lock behind the excavation chamber) |

|

(Image: Microtunnelling machine with auger spoil removal ? cutting head) |

|

|

|

Underground … |

|

|

|

|

|

(Image: Manned techniques)

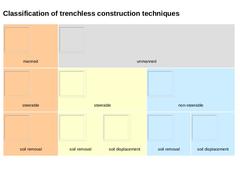

manned |

(Image: Unmanned techniques)

unmanned |

|

(Image: Steerable techniques)

steerable |

(Image: Steerable techniques)

steerable |

(Image: Non-steerable techniques)

non-steerable |

|

(Image: Soil removal techniques)

soil removal |

(Image: Soil removal techniques)

soil removal |

(Image: Soil displacement techniques)

soil displacement |

(Image: Soil removal techniques)

soil removal |

(Image: Soil displacement techniques)

soil displacement |

|

|

|

(Image: Manned techniques) Manned technique:

Technique involving the use of personnel working in the excavated bore during installation [DINEN12889:2000]. |

|

|

|

(Image: Unmanned techniques) Unmanned technique:

Technique avoiding the use of personnel working in the excavated bore during installation [DINEN12889:2000]. |

|

|

|

(Image: Steerable techniques)

Steerable techniques:

Techniques which allow for a correction of the direction of the cutting head, the steel pipe joint or auger flight [Stein05a]. |

|

|

|

(Image: Non-steerable techniques)

Non-steerable techniques:

Techniques which do not allow for a correction of the direction of the cutting head, the steel pipe joint or auger flight [Stein05a]. |

|

|

|

(Image: Soil removal techniques)

Soil removal techniques:

Jacking pipes are jacked either dynamically or statically from a starting shaft to a target shaft whereby the soil or rock material loosened by the jacking is transported away either continuously, in intervals or after the boring [Stein05a]. |

|

|

|

(Image: Soil displacement techniques)

Soil displacement techniques:

Static or dynamic jacking of jacking pipes by displacement of the in situ soil … |

|

|

|

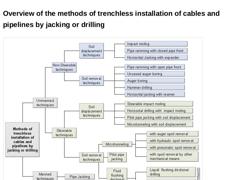

(Image: Overview of the methods of trenchless installation of cables and pipelines by jacking or drilling) |

|

|

|

|

|

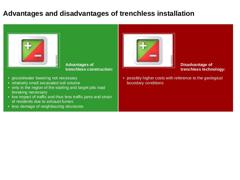

(Image: Pros and cons)

Advantages of trenchless construction: -

groundwater lowering not necessary

-

relatively small excavated soil volume

-

only in the region of the starting and target pits road breaking necessary

-

low impact of traffic and thus less traffic jams and strain of residents due to exhaust fumes

-

less damage of neighbouring structures

|

(Image: Pros and cons)

Disadvantage of trenchless technology: -

possibly higher costs with reference …

|

|

|

|

|

Today, the installation of gas, water, and wastewater pipelines is still predominantly carried out using the open trench installation. In view of the numerous disadvantages associated with this method, it is imperative that in the future trenchless pipeline construction be considered much more strongly as an alternative in the planning and construction of sewers and pipelines. For a better understanding of the complexity of the inner-city subsoil, this module provides a brief introduction to infrastructures in the urban subsoil. After completing this module, you will have knowledge regarding: - prerequisites for a functioning infrastructure;

- options for new pipeline construction;

- procedures for trenchless pipeline construction; and

- advantages over the open cut method.

|

|

Today, supply and discharge lines are still predominantly installed by using the open-cut method: a trench is dug, the lines are installed. Under the protection of an embankment or sheeting and the trench is filled afterwards. In the face of the numerous disadvantages as well as the citizens' growing environmental consciousness in the future it is urgently necessary to take trenchless technology into account much stronger than until today as an alternative … |

|

|

(Image: Starting and target shafts) |

Shaft:

Depression in the ground surface that is created by sinking (excavation or vertical boring), with suitable securing, that serves for the underground creation of bore holes with the aid of the methods of trenchless installation and for the transport of humans, machines, substances (spoil, air for ventilation, water, bentonite suspension, etc.) and auxiliary materials (pipes, cables, hoses) as well as power … |

|

|

|

(Image: Starting and target shafts) |

Shaft construction:

Method for sinking and securing of shafts [Olsha91]. |

|

|

|

Support (or securing):

Measures taken to prevent the collapse of the shaft (with reference to [DS853]) [Stein05a]. |

|

|

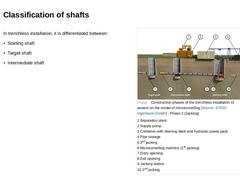

In trenchless installation, it is differentiated between: -

Starting shaft

-

Target shaft

-

Intermediate shaft

(Image: Construction phases of the trenchless installation of sewers on the model of microtunnelling - Phase 2 (Jacking)) |

|

|

(Image: Starting and target shafts) |

Starting shaft:

An auxiliary construction in the form of a shaft from which the jacking is started (based on [DS853]) [Stein05a]. |

Target shaft:

An auxiliary construction in the form of a shaft in which the jacking ends (also called destination shaft) (based on [DS853]) [Stein05a]. |

Intermediate shaft:

Auxiliary structure in the form of a shaft which is passed through planned (e.g. for maintenance, tool change, … |

|

|

(Image: Starting and target shafts) For instance, in microtunnelling and pipe jacking, the following occurs at the starting shaft: -

Installation of the (main) jacking station and the abutment for introducing the jacking forces into the subsoil

-

Positioning the microtunnelling or shield machine

-

Installation of the fixed portions of the measuring system

-

Installation of the individual jacking pipes

-

Discharging the spoil excavated at the working face …

|

|

|

(Image: Starting and target shafts) |

The duties of a target shaft are greatly determined by the methods in use. In microtunnelling and pipe jacking, it is used mainly for removing the microtunnelling or shield machine. Target shafts are not used, for instance with blind boring, in the creation of service pipes by means of boring with underground connection to a pipe and sea outfalls in which the microtunnelling or shield machine is removed under … |

|

|

|

(Image: Starting and target shafts) |

Intermediate shafts are used for long jacking lengths in order to carry out planned works such as a change of excavation tools or other maintenance measures to the microtunnelling or shield machine. |

|

(Image: View into an intermediate shaft)

Example of an intermediate shaft |

|

|

|

|

| (Image: Planning) In trenchless installation, shafts are the only structures that must be installed in the open-cut method of construction. | | (Image: Attention!) | In the interest of minimising the environmental disturbance as well as the construction costs associated with this, great importance is attached to the following planning aspects: - Selection of the location

- Quantity

- Form and dimensions

- Shaft construction method and support.

|

|

|

|

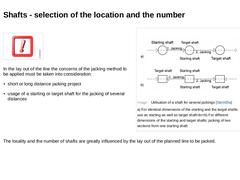

(Image: Attention!) In the lay out of the line the concerns of the jacking method to be applied must be taken into consideration: (Image: Utilisation of a shaft for several jackings [Stein05a]) The locality and the number of shafts are greatly influenced by the lay out of the planned line to be jacked. |

|

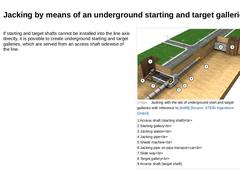

If starting and target shafts cannot be installed into the line axis directly, it is possible to create underground starting and target galleries, which are served from an access shaft sidewise of the line. (Image: Jacking with the aid of underground start and target galleries with reference to [Ito98] [Image: S&P GmbH]) |

|

The shape and dimensions of shafts should be planned and built under the aspect of minimising expected emissions and construction costs as well as work and health protection. |

(Image: Cross sectional shapes of starting and target shafts) |

|

(Image: Attention!)

Shafts in which work is carried out must have sufficient working space. The dimensions of the working space depend on the slope angle, lining, equipment, type of pipe and method of working [… |

|

|

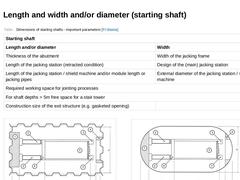

(Table: Dimensions of starting shafts - important parameters [FI-Steina]) | | (Image: Starting shaft dimensions for jacking pipes of 2.43 m lenght for rectangular shape of shaft and sheet pile wall lining for pre-defined microtunnelling or shield machine and jacking station [FI-Toyot])

| (Image: Starting shaft dimensions for jacking pipes of 2.43 m lenght for rectangular shape of shaft with semi-circular rounded faces and lining of liner plates for pre-… |

|