|

The main field of application for cement mortar coatings has ranged since the start of the 20th Century to the works or in-situ applied corrosion protection of steel or cast iron drinking water piping. Much experience has been gained and many publications are available that provide information on the requirements, the composition of mortar, layer thicknesses, types of application as well as the method of action of this corrosion protection. |

|

Silicate mortar is a two-component pure mineral inorganic building material. As a rule, alkali silicate mortar consists of a modified, highly alkaline, silicate solvent as a fluid component. The powder components contain mixtures of various synthetic and natural latent-hydraulic substances, crystalline aggregates as well as other accompanying substances. In the alkaline silicate mortars, other than with cement-bound building materials, an amorphous … |

|

Mineral mortars are understood to be materials that have no plastics additives. In the following, the mortars belonging to this group will be described as cement mortars (Abschnitt 5.3.1.3.2.1) and silica mortars (Abschnitt 5.3.1.3.2.2). |

|

One possibility of targeted improvement of, among others, the bending-tensile strength, the adhesive-tensile strength, the resistance to chemical attacks as well as the resistance to diffusion, of pure cement mortars for coating is offered by the use of plastics additives to the cement mortar [Fiebr85]. These mortars are designated as plastics-modified cement mortars and in the English usage also as polymer-modified cement mortar (Polymer Cement Concrete - … |

|

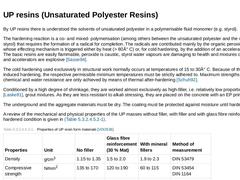

By UP resins there is understood the solvents of unsaturated polyester in a polymerisable fluid monomer (e.g. styrol). The hardening reaction is a co- and mixed- polymerisation (among others between the unsaturated polyester and the vulcanised styrol) that requires the formation of a radical for completion. The radicals are contributed mainly by the organic peroxides (hardener) whose effecting mechanism is triggered either by heat (> 80° C) or, for … |

|

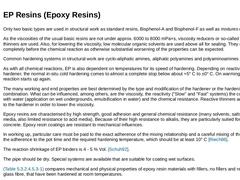

Only two basic types are used in structural work as standard resins, Bisphenol-A and Bisphenol-F as well as mixtures of the two. As the viscosities of the usual basic resins are not under approx. 6000 to 8000 mPa×s, viscosity reducers or so-called reactive thinners are used. Also, for lowering the viscosity, low molecular organic solvents are used above all for sealing. They must soften completely before the chemical reaction as otherwise substantial … |

|

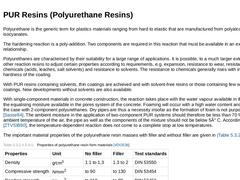

Polyurethane is the generic term for plastics materials ranging from hard to elastic that are manufactured from polyalcohols and poly-isocyanates. The hardening reaction is a poly-addition. Two components are required in this reaction that must be available in an exact mixture relationship. Polyurethanes are characterised by their suitability for a large range of applications. It is possible, to a much larger extent than with other reaction resins … |

|

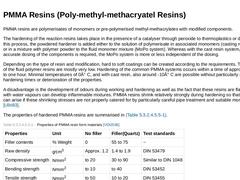

PMMA resins are polymerisates of monomers or pre-polymerised methyl-methacrylates with modified components. The hardening of the reaction resins takes place in the presence of a catalyser through peroxide to thermoplastics or duromers. In this process, the powdered hardener is added either to the solution of polymerisate in associated monomers (casting resin system) or in a mixture with polymer powder to the fluid monomer mixture (MoPo system). Whereas … |

|

If a mortar contains no cement and if the whole binding medium consists of a synthetic resin mixture capable of reaction at the usual construction temperatures, then one talks of a reaction resin mortar or, in short, of a PC (Polymer Concrete). In use are reaction resin systems based on unsaturated polyesters, epoxy resins and methacryl resins that are "cold hardening", i.e. they can harden completely at room temperatures. As a result of the lack … |

|

|

|

|

(Image: Stresses in the connection joint as a result of shrinkage of the coating [Schmi86])

|

|

(Image: Testing the surface adhesive tensile strength - Fixing the test block)

|

|

(Image: Testing the surface adhesive tensile strength - Tearing the test block off)

|

|

(Image: Testing the surface adhesive tensile strength - Test block after testing)

|

|

(Image: Concrete surface on inside of pipe prepared for application of coating (2 x sand blasting and 2 … |

|

|

The example for this method of coating is the creation, securing or lining in galleries and tunnels with the aid of the shuttering common there [DGEG86b] [Maak86] [Maidl84b]. In this process, convertible shuttering or special shuttering carts (Bild 5.3.1.6.1) (Bild 5.3.1.6.1) are used. Depending on the size of the tunnel shuttering, mechanical or hydraulic devices can be built in for helping to install and remove the shuttering. |

(Image: Sewer shuttering … |

|

|

|

(Image: Cement grout injection method with reference to [TGL34011] [Image: S&P GmbH])

|

|

(Image: Influences to be considered in the determination of the injection pressure in the ZMA process with reference to [Böhm78] [Image: S&P GmbH])

|

In contrast to the water supply sector, there is at present no experience in the application of in-situ concrete lining processes for rehabilitation of non-man-accessible sewers. A representative of this group of … |

|

In the in-situ concrete lining process, an annular space is created by means of a shuttering inserted into the sewer and into this a suitable grout or concrete on a cement and/or reaction resin base is injected. The work can be carried out in man-accessible as well as non-man-accessible cross sections. After reaching the required least strength, the shuttering is removed. |

|

In the displacement process, a displacement body whose outside diameter is smaller than the inside diameter of the pipe to be coated by the amount of the layer thickness to be applied, is pulled or pressed centrally through the respective section of the sewer. The coating material in front of it, in the direction of flow, is displaced into the annular space between the piping and displacement body and is pressed by it against the pipe inner wall.… |

|

According to DIN 18551 [DIN18551:1992], gunite is a "concrete that is conveyed in a closed pressure-resistant hose or pipe to the site and is there applied by means of spraying and thus consolidated." In principle it is not differentiated in its composition from the usual in-situ concrete. The difference is in the conveying, insertion and consolidation, i.e. in the working that is combined into one working step, the spraying. Shuttering and vibration … |

|

The Hochtief AG has developed a special gunite lining process of a two-layer rehabilitation system in which the first layer is used as a back anchor for the second layer [Hille87]. The back anchoring is created by means of a plastics-modified gunite (SPCC) with polyacryl-nitrile fibres. In order to create the SPCC preparatory mixture (gunite plastics-modified cement mortar), water-emulsified epoxy resin is used that, according to [ZTVSIB90], particularly … |

|

A large part of the accident and health dangers mentioned in the section "Gunite and gunite mortar" are avoided by the "Ruswroe System" specially developed in England for the coating of sewers [FI-Alpha] [Marti84]. It is based on the wet gunite lining system with the utilisation of a very low pressure (comparable to the application of plaster with plaster spray machines). The mortar used is applied onto a galvanised mesh wire mat with a mesh thickness … |

|

(Image: Sketch of the principle of an automatic spray machine for dry (right) and wet (left) gunite process for coating large boreholes in the coal mining industry [Großk85]) In order to improve coatings based on the gunite lining process as regards costs, material quality as well as accidents and injuries, present efforts are aimed at mechanisation.

A first attempt in this respect was with the spray machine used in the Pre-load process [Atkin50] … |

|

|

|

(Image: Applying cement grout by spray lining in non-man-accessible sewers - Rotary spray heads with coupled smoothing cones [FI-Heitkb]) The Centriline process or cement mortar coating with the spray lining process was developed specially for water supply pipes or pipelines of steel or cast iron. Even today, this is the main use of the application for nominal sizes from DN 80 and almost without limits upwards (Bild 5.3.1.9.1.1). For this purpose there … |

|

(Image: Working opening in the opened-up semi-cylinder channel [FI-Teerb]) The work can generally be carried out from the manholes. Depending on the dimensions of the machines to be used, excavations may be necessary. For pressure piping of steel, the required working openings are effected in an excavation by removing a piece of the piping approximately 2 m in length or by cutting open a semi-cylindrical section with chamfered, or even better, rounded, … |

|

After insertion and centring the spray lining machine at one end of the section of the sewer to be rehabilitated, the machine is pulled or driven backwards through the section of the sewer at a constant velocity during which the spraying of the mortar onto the inner surface of the pipe is carried out by means of a rapidly rotating spray head operated by compressed air or an electric motor (Bild 5.3.1.9.1.2.2) (Bild 5.3.1.9.1.2.2). The mortar is … |

|

|

|

The special equipment used in the different variants of the Centriline procedure can be seen from the corresponding depictions. Approximately 6 persons are required for the utilisation of non-self-propelling equipment, for self- propelling machines, approx. 8 persons are required. |