|

Polymerbeton besteht aus einem Gemisch von mineralischen, quarzitischen Füllstoffen im porenarmen Sieblinienbereich nach DIN 1045‑2 [ [DIN1045-2:2001]] und Reaktionsharz auf Basis von ungesättigten Polyesterharzen mit Eigenschaften nach DIN 16946 Teil 2, Tabelle 3 [ [DIN16946:1989]]. Die Werkstoffeigenschaften von Polymerbeton am Beispiel der POLYCRETE®-Rohre enthält nachfolgende Auflistung [ [Meyer2012]]: -

Wichte [γR] 23 kN/m3

-

E-Modul [ERK] 28.000 …

|

|

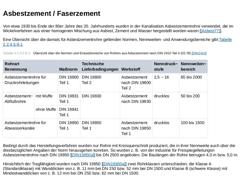

Von etwa 1930 bis Ende der 80er Jahre des 20. Jahrhunderts wurden in der Kanalisation Asbestzementrohre verwendet, die im Wickelverfahren aus einer homogenen Mischung aus Asbest, Zement und Wasser hergestellt worden waren [ [Asbest77]]. Eine Übersicht über die damals für Asbestzementrohre geltenden Normen, Nennweiten- und Anwendungsbereiche gibt Tabelle 1‑58. (Tabelle: Übersicht über die Normen und Einsatzbereiche von Rohren aus Asbestzement nach DIN … |

|

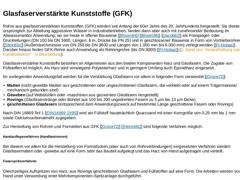

Rohre aus glasfaserverstärkten Kunststoffen (GFK) werden seit Anfang der 60er Jahre des 20. Jahrhunderts hergestellt. Sie dienten ursprünglich zur Ableitung aggressiver Wässer in Industriebetrieben, fanden dann aber auch mit zunehmender Bedeutung im Abwassersektor Anwendung, wo sie heute in offener Bauweise [ [Bloom84]] [ [Bloom86]] [ [Jacob82]] als Freispiegel- oder Druckleitungen (DN 100 bis DN 3600, Längen: 6 m, Drücke bis PN 25) und in geschlossener … |

|

Den größten Anteil an den Bauwerken von Entwässerungssystemen ( (Allgemeines)) nehmen die Schächte und Kontrollschächte nach DIN EN 476 [ [EN476:2011]] ein. Letztere werden nach DIN EN 752 [ [EN752:2008]] als Inspektionsöffnungen bezeichnet. |

|

|

|

Die DIN EN 752 [ [EN752:2008]] definiert die Inspektionsöffnung wie folgt: „Öffnung mit abnehmbarem Deckel, angebracht auf einer Abwasserleitung oder einem Abwasserkanal, die die Zugänglichkeit nur von der Oberfläche aus erlaubt, nicht jedoch den Einstieg von Personen gestattet.“ In DIN EN 476 [ [EN476:2011]] werden diese Öffnungen, die einen Innendurchmesser von weniger als 800 mm besitzen, als Kontrollschächte bezeichnet, die das Einbringen einer … |

|

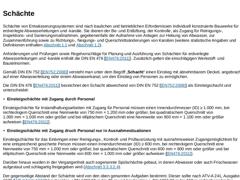

Schächte von Entwässerungssystemen sind nach baulichen und betrieblichen Erfordernissen individuell konstruierte Bauwerke für erdverlegte Abwasserleitungen und -kanäle. Sie dienen der Be- und Entlüftung, der Kontrolle, als Zugang für Reinigungs-, Inspektions- und Sanierungsmaßnahmen, gegebenenfalls der Aufnahme von Anlagen zur Hebung von Abwasser, zur Zusammenführung sowie zu Richtungs-, Neigungs- und Querschnittsänderungen von Kanälen (weitere statistische … |

|

Den Stand der Technik der vornehmlich eingesetzten, vorgefertigten Schächte bzw. Schachtfertigteile aus Beton und Stahlbeton bis 2004 dokumentierte die DIN 4034 Teil 1 [ [DIN4034-1:1993]]. Seit November 2004 gelten für Schächte aus Beton, Stahlfaserbeton und Stahlbeton die DIN EN 1917 [ [EN1917:2003/8]] (Bild 1‑190) zusammen mit der nationalen Ergänzungsnorm DIN V 4034-1 [ [DIN4034-1:1993]]. Danach dürfen in Deutschland für Abwasserleitungen und -… |

|

Neben Schächten aus Fertigteilen wurden und werden diese nach wie vor auch örtlich aus Mauerwerk hergestellt. Angaben über die Ausführung im 19. und 20. Jahrhundert (Bild 1‑214) (Bild 1‑215) enthält (Bruchsteine, Werksteine, Kanalklinker). (Bild: Gemauerte Einsteigschächte der Kanalisation von Berlin um 1884 [Hobre84]) (Bild: Herstellung eines gemauerten Schachtes) Seit dem Jahre 2000 gilt für Bauwerke aus Kanalklinkern, die neu errichtet oder saniert … |

|

Neben den Schächten aus Beton- und Stahlbetonfertigteilen sowie gemauerten Schächten werden seit einigen Jahrzehnten auch vorgefertigte Schächte aus anderen Werkstoffen (z. B. aus Steinzeug (Bild 1‑216) (Bild 1‑217) (Bild 1‑218), Faserzement oder Kunststoffen (Bild 1‑220) oder aus Kombinationen verschiedener Werkstoffe (Bild 1‑219) eingesetzt. (Bild: Schachtunterteile aus Steinzeug [FI-Stein]) (Bild: Draufsicht auf einen Schacht aus Steinzeug mit … |

|

Schächte sind mit Steighilfen auszurüsten (einläufige oder zweiläufige Steigeisengänge bzw. ortsfeste oder bewegliche Steigleitern). Aufgrund der beengten Platzverhältnisse und der eingeschränkten Sichtbedingungen ist eine einheitliche Ausführung der Steighilfen in allen Schächten eines Entwässerungssystems wegen der Sicherheit gebenden Routine wichtig. Zusätzlich sind oberhalb von Einstiegsstellen geeignete Haltevorrichtungen anzuordnen [ [ATVA157:… |

|

Bei Schächten für Abwasserleitungen und -kanäle mit Nennweiten ≥ DN 700 können diese nach DIN V 1201 [ [DINV1201:2003]] auch seitlich (tangential) an Rohre angeformt werden (Bild 1‑225) (Bild 1‑226) (Bild 1‑227). (Bild: Schächte mit seitlich angeordnetem Einstieg - Tangentialschacht mit einseitigem Auftritt [ATVA241a]) (Bild: Schächte mit seitlich angeordnetem Einstieg - Tangentialschacht ohne Auftritt (Regen- oder Entlastungskanäle) [ATVA241a]) (… |

|

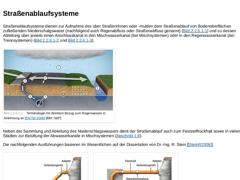

Straßenablaufsysteme dienen zur Aufnahme des über Straßenrinnen oder -mulden dem Straßenablauf von Bodenoberflächen zufließenden Niederschalgswaser (nachfolgend auch Regenabfluss oder Straßenabfluss genannt) (Bild 1-12) und zu dessen Ableitung über jeweils einen Anschlusskanal in den Mischwasserkanal (bei Mischsystemen) oder in den Regenwasserkanal (bei Trennsystemen) (1‑235a und b). (Bild: Terminologie mit direktem Bezug zum Regenwasser) Neben der … |

|

|

|

Seit ca. 30 Jahren beschäftigt man sich immer wieder mit der Weiterentwicklung von Straßenabläufen mit der Zielstellung, durch technische und konstruktive Veränderungen die Reinigung dieser Anlagen [ [Grott1991]] [ [Giesl1997]] [ [[Butle1998]]] und insbesondere den Feststoffrückhalt zu verbessern [ [SteinR04a]] [ [SteinR2005]]. In den letzten Jahren wurden die Zielstellungen dahingehend erweitert, Straßenabläufe auch als dezentrale Anlagen zur Behandlung … |

|

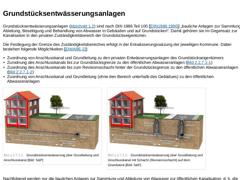

Grundstücksentwässerungsanlagen ( (Begriffe/Freispiegelsystem)) sind nach DIN 1986 Teil 100 [ [DIN1986:1990]] „bauliche Anlagen zur Sammlung, Ableitung, Beseitigung und Behandlung von Abwasser in Gebäuden und auf Grundstücken“. Damit gehören sie im Gegensatz zur Kanalisation in den privaten Zuständigkeitsbereich der Grundstückseigentümer. Die Festlegung der Grenze des Zuständigkeitsbereiches erfolgt in der Entwässerungssatzung der jeweiligen Kommune. … |

|

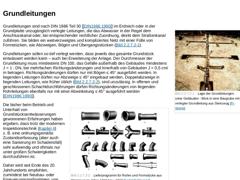

(Bild: Lage der Grundleitungen unter Gebäuden - Blick in eine Baugrube mit verlegter Grundleitung aus Steinzeug [FI-Steinb]) Grundleitungen sind nach DIN 1986 Teil 30 [ [DIN1986:1990]] im Erdreich oder in der Grundplatte unzugänglich verlegte Leitungen, die das Abwasser in der Regel dem Anschlusskanal oder, bei entsprechender rechtlicher Zuordnung, direkt dem Straßenkanal zuführen. Sie bilden ein weitverzweigtes und kompliziertes Netz mit einer Fülle … |

|

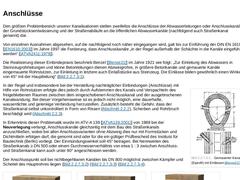

Den größten Problembereich unserer Kanalisationen stellen zweifellos die Anschlüsse der Abwasserleitungen oder Anschlusskanäle der Grundstücksentwässerung und der Straßenabläufe an die öffentlichen Abwasserkanäle (nachfolgend auch Straßenkanal genannt) dar. Von einzelnen Ausnahmen abgesehen, auf die nachfolgend noch näher eingegangen wird, galt bis zur Einführung der DIN EN 1610 [ [EN1610:2003]] im Jahre 1997 die Forderung, dass Anschlusskanäle „in … |

|

Straßenabläufe wurden seit Beginn der Errichtung von Kanalisationen im 19. Jahrhundert auch unter den Bezeichnungen „Straßeneinlass“, „Sinkkasten“, „Gully“ oder „Trumme“ eingesetzt, wobei sich die konstruktive Gestaltung im Laufe der Zeit durch veränderte Anforderungen gewandelt hat. Schon früher wurden folgende zwei in ihrer Konstruktion unterschiedliche Bauarten von Straßenabläufen eingesetzt: -

Straßenablauf mit Bodenauslauf

-

Straßenablauf mit Schlammraum

|

|

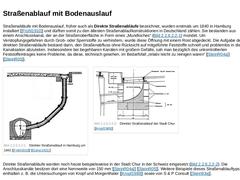

Straßenabläufe mit Bodenauslauf, früher auch als Direkte Straßenabläufe bezeichnet, wurden erstmals um 1840 in Hamburg installiert [ [Frühl1910]] und dürften somit zu den ältesten Straßenablaufkonstruktionen in Deutschland zählen. Sie bestanden aus einem Anschlusskanal, der an der Straßenoberfläche in Form eines „Mundloches“ (Bild 1‑236) mündet. Um Verstopfungsgefahren durch Grob- oder Sperrstoffe zu verhindern, wurde diese Öffnung mit einem Rost … |

|

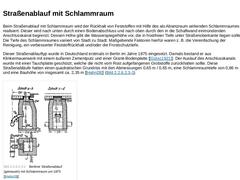

Beim Straßenablauf mit Schlammraum wird der Rückhalt von Feststoffen mit Hilfe des als Absetzraum wirkenden Schlammraumes realisiert. Dieser wird nach unten durch einen Bodenabschluss und nach oben durch den in die Schaftwand einmündenden Anschlusskanal begrenzt. Dessen Höhe gibt die Wasserspiegelhöhe vor, die in frostfreier Tiefe unter Straßenoberkante liegen sollte. Die Tiefe des Schlammraumes variiert von Stadt zu Stadt. Maßgebende Faktoren hierfür … |

|

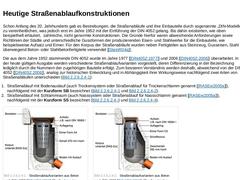

Schon Anfang des 20. Jahrhunderts gab es Bestrebungen, die Straßenabläufe und ihre Einbauteile durch sogenannte „DIN-Modelle“ zu vereinheitlichen, was jedoch erst im Jahre 1952 mit der Einführung der DIN 4052 gelang. Bis dahin existierten, wie oben beispielhaft erläutert, zahlreiche, nicht genormte Konstruktionen. Die Gründe hierfür waren abweichende Anforderungen sowie Richtlinien der Städte und unterschiedliche Gussformen der produzierenden Eisen- … |

|

Der vor Beginn der Baumaßnahme vor Ort vorhandene Baugrund wird wegen seines unterschiedlichen Verhaltens bei der Belastung durch Bauwerke nach DIN EN 1997-1 [ [EN1997-1:2014]] in Boden und Auffüllung (zusammen nachfolgend als Lockergestein bezeichnet) sowie in Fels (Festgestein) unterteilt. Gegenstand der nachfolgenden Ausführungen sind die Lockergesteine, da diese im hier betrachteten oberflächennahen Bereich in der Bundesrepublik Deutschland vorwiegend … |

|

Nichtbindige Böden Bei nichtbindigen Böden bilden die einzelnen Mineralkörner oder Gesteinsteilchen ein Haufwerk, das durch Reibung der Kornflächen aneinander einen losen Zusammenhalt besitzt. Ihre Eigenschaften werden von der Korngröße, Korngrößenverteilung, Kornform und Kornrauigkeit beeinflusst. Gegenüber Witterungseinflüssen sind sie je nach Grundmaterial beständig. Zu den nichtbindigen Böden gehören nach DIN 1054 [ [DIN1054:2010]] Sande, Kiese, … |

|

Bei feinkörnigen Böden ist die Kornform allein von der Mineralart abhängig. In der Regel sind Quarz, Kalk und Dolomit kubisch, Tonminerale flach und Halloysit (Schichtsilikat) länglich. Bei grobkörnigen Böden sind Kornform und Kornrauigkeit von der Gesteinsart sowie der Transport- und Verwitterungsgeschichte abhängig. Zunehmender Transportweg führt zur Rundung der Kanten und zur Glättung des Korns. Verwitterung kann die Kornrauigkeit dagegen wieder … |