|

Überschüttungsbedingungen nach ATV-A 127 [ATVA127:1988] (Abschnitt 5.2.1.2): - A1: Lagenweise gegen den gewachsenen Boden verdichtete Grabenverfüllung (ohne Nachweis des Verdichtungsgrades); gilt auch für Trägerbohlwände (Berliner Verbau).

- A2: Senkrechter Verbau des Rohrgrabens mit Kanaldielen, die erst nach dem Verfüllen gezogen werden.

Verbauplatten oder -geräte, die bei der Verfüllung des Grabens schrittweise entfernt werden.

Unverdichtete Grabenverfüllung.

|

|

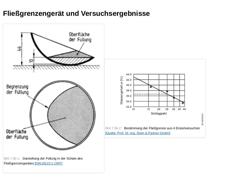

| (Bild: Darstellung der Füllung in der Schale des Fließgrenzengerätes [DIN18122-1]) | (Bild: Bestimmung der Fließgrenze aus 4 Einzelversuchen) |

|

|

Empfindlichkeit gegenüber Änderungen des Wassergehaltes: Bei kleiner Plastizität genügt bereits eine geringe Wassermenge, um einen festen Boden bei entsprechender mechanischer Beanspruchung in breiige Konsistenz übergehen zu lassen. Dies gilt insbesondere für Böden, deren natürlicher Wassergehalt w nahe dem Wassergehalt an der Fließgrenze wL liegt. Mit abnehmendem Wassergehalt nimmt das Volumen einer bindigen Bodenprobe ab. Die Probe schrumpft dabei … |

|

(Bild: Zustandsformen und -grenzen (Quelle: Uni Essen, Übung Bodenmechanik)) Im Ausland ist auch der sog. liquidity index IL =1- IC = (w - wP) / IP gebräuchlich |

|

Leicht plastische Tone bestehen von der Korngröße her überwiegend aus Schluff! |

|

Im englischen Sprachraum wird als Bezugswert meist die sog. modifizierte Proctordichte mod ρPr verwendet, bei der eine größere Verdichtungsarbeit geleistet wird. Vgl. hierzu auch DIN 18127 [DIN18127:1997] (Bild: Manuelle Proctorgeräte [FI-Röhre]) (Tabelle: Maße und Versuchsbedingungen zur Bestimmung der einfachen Proctordichte [DIN18127]) (Tabelle: Proctorversuch - Probemenge für den Einzelversuch und zulässiges Größtkorn [DIN18127]) |

|

Die Sättigungslinie wird in Abhängigkeit der Korndichte ρs des Prüfmaterials (zu bestimmen nach DIN 18124 [DIN18124]), der Dichte ρw von Wasser und dem Wassergehalt w berechnet. |

|

(Tabelle: Übersicht über Proctordichte und optimalen Wassergehalt ausgewählter Bodengruppen [Pulsf01]) | (Bild: Beziehung zwischen Trockendichte ρd und Wassergehalt w für bindige Böden aus einfachen Proctorversuchen mit einer Verdichtungsarbeit von W = 0,6 MN/m³ [Schmi01a]) | (Bild: Beziehung zwischen Trockendichte ρd und Wassergehalt w für nichtbindige Böden aus einfachen Proctorversuchen mit einer Verdichtungsarbeit von W = 0,6 MN/m³ [Schmi01a]) | | (… |

|

|

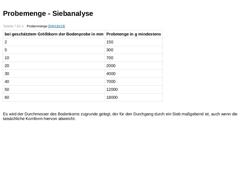

(Tabelle: Probenmenge [DIN18123]) Es wird der Durchmesser des Bodenkorns zugrunde gelegt, der für den Durchgang durch ein Sieb maßgebend ist, auch wenn die tatsächliche Kornform hiervon abweicht. |

|

Um so mehr ein Verfüllhorizont verdichtet wurde, desto mehr überwiegen im Schwingverhalten der Platte die elastischen Anteile gegenüber den nicht reversiblen, plastischen Anteilen. |

|

Die Vorbelastung dient - wie beim statischen Plattendruckversuch auch - als Kontrolle dafür, dass die erforderliche Verdichtung nicht durch die Belastung beim eigentlichen Versuch herbeigeführt worden ist. |

|

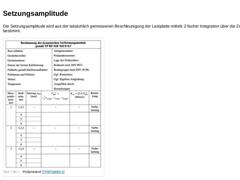

Die Setzungsamplitude wird aus der tatsächlich gemessenen Beschleunigung der Lastplatte mittels 2-facher Integration über die Zeit bestimmt. (Bild: Prüfprotokoll [TPBFStBB8-3]) |

|

Ungewöhnliche Versuchsergebnisse wie große Unterschiede zwischen den gemessenen Setzungen der drei Messstöße können z.B. infolge Verkantung der Lastplatte auftreten. |

|

(Tabelle: Probenmenge [DIN18123]) |

|

Werden Baumaschinen als Belastungswiderlager verwendet, sollten nach Möglichkeit Baumaschinen ohne Stossdämpfer verwendet werden bzw. darauf geachtet werden, dass bewegliche Bauteile möglichst wenig Spiel haben, um die Ergebnisse nicht zu verfälschen. Beladene LkW oder schwere Radlader sind daher nur bedingt als Belastungswiderlager geeignet. |

|

Mittels knicksteifer Verlängerungselemente kann der Hydraulikzylinder - auch zum Ausgleich unterschiedlicher Abstände zum Belastungswiderlager - bis auf rd. 1000 mm verlängert werden. - Lastplattendurchmesser 300 mm: Auflösung Spannungsanzeige mind. 0,001 MN / m2

- Lastplattendurchmesser 600 mm und 762 mm: Auflösung Spannungsanzeige mind. 0,0001 MN / m2

Die Auflösung einer Kraftanzeige muss gleichwertig sein. |

|

- Lastplattendurchmesser 300 mm: Lichter Abstand mind. 0,75 m

- Lastplattendurchmesser 600 mm: Lichter Abstand mind. 1,10 m

- Lastplattendurchmesser 762 mm: Lichter Abstand mind. 1,30 m

|

|

- Lastplattendurchmesser 300 mm und Lastplattendurchmesser 600 mm: Vorbelastung 0,01 MN / m2

- Lastplattendurchmesser 762 mm: Vorbelastung 0,005 MN / m2.

Die Vorbelastung dient - wie beim dynamischen Plattendruckversuch auch - als Kontrolle dafür, dass die erforderliche Verdichtung nicht durch die Belastung beim eigentlichen Versuch herbeigeführt worden ist. |

|

| (Bild: Statischer Plattendruckversuch [FI-IBG]) | | (Bild: Statischer Plattendruckversuch - Detail [FI-IBG]) |

In der Regel werden maximale Last / maximale Setzung wie folgt angesetzt: - Lastplattendurchmesser 300 mm: Maximale Spannung unter der Lastplatte 0,50 MN / m2 o. maximale Setzung 5 mm

- Lastplattendurchmesser 600 mm: Maximale Spannung unter der Lastplatte 0,25 MN / m2 o. maximale Setzung 8 mm

- Lastplattendurchmesser 762 mm: Maximale Spannung unter der …

|

|

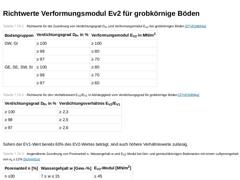

(Tabelle: Richtwerte für die Zuordnung von Verdichtungsgrad D_Pr und Verformungsmodul E_V2 bei grobkörnigen Böden [ZTVEStB94a]) (Tabelle: Richtwerte für den Verhältniswert E_V2/E_V1 in Abhängigkeit vom Verdichtungsgrad für grobkörnige Böden [ZTVEStB94a]) Sofern der EV1-Wert bereits 60% des EV2-Wertes beträgt, sind auch höhere Verhältniswerte zulässig. (Tabelle: Angenäherte Zuordnung von Porenanteil n, Wassergehalt w und E_V2-Modul bei fein- und gemischtkörnigen … |

|

Abmessungen des Ausstechzylinders: Verhältnis h / d1 ≈ 1,2 und Flächenverhältnis ca = (da2 - di2) / di2 ≤ 0,1 |

|

(Bild: Eintreiben eines Ausstechzylinders in aufbereiteten Verfüllboden) Wenn ein Eindrücken nicht möglich ist, kann der Ausstechzylinder mit einem Fallbär oder notfalls mit einem Hammer eingetrieben werden Bei sandigen Böden kann sich die Probe auflockern oder verdichten, die Probenoberfläche liegt dann nicht mehr auf gleicher Höhe mit der Bodenoberfläche. Sofern das Gerät zur Entnahme von Sonderproben aus Schürfen nach DIN 4021 [DIN4021:1990] verwandt … |

|

Die Trockenmasse md lässt sich auch aus der feuchten Masse m und dem Wassergehalt w der Probe errechnen. |

|

Der Zusammenhang zwischen den Ergebnissen des dynamischen Plattendruckversuchs mit den Anforderungswerten ist zu ermitteln. Beispiele für die Vorgehensweise gibt die im Straßenbau geltende TP BF - StB E 4 [TPBFStBE4]. |

|

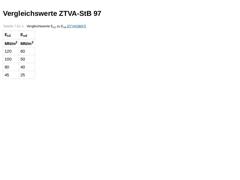

(Tabelle: Vergleichswerte E_v2 zu E_vd [ZTVAStB97]) |