|

|

(Bild: Rohrverbindung mit elastischem Dichtmittel) |

Elastische Dichtmittel

Elastische Dichtmittel sind Dichtmittel aus Elastomeren (s. DIN 7724) [DIN7724:1993], die durch elastische Verformung in die zu dichtenden Fugen eingebracht werden. Ihre Dichtwirkung gegen unter Druck stehende Flüssigkeiten ist abhängig von den durch die Verformung des Dichtmittels entstehenden gummielastischen Rückstellkräften. |

|

(Bild: Fugenverguss mit Gießring - Dichtung … |

|

|

(Video: Rollringdichtung)

Video: Rollringdichtung [Quelle: S&P GmbH]. Dieses interaktive Objekt ist ausschließlich in der Online-Version des Moduls sichtbar. Die verbreitetste Art der Elastomerdichtungen war die Rollringdichtung . Der Elastomerring wird unter Vordehnung auf das Spitzende des Rohres aufgezogen und rollt unter gleichzeitiger Verformung beim Überschieben des Stumpfendes bzw. der Muffe des angrenzenden Rohres in seine endgültige Lage. … |

|

|

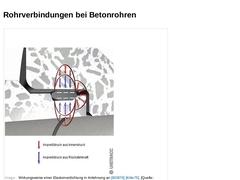

| (Bild: Wirkungsweise einer Elastomerdichtung in Anlehnung an [BDB78] [Kitte75]) |

|

|

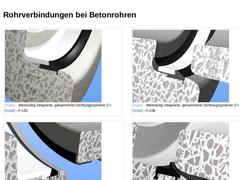

| (Bild: Werkseitig integrierte, gekammerte Dichtungssysteme [FI-Forsh] - F-103)

| (Bild: Werkseitig integrierte, gekammerte Dichtungssysteme [FI-Forsh] - F-106)

| | (Bild: Werkseitig integrierte, gekammerte Dichtungssysteme [FI-Forsh] - F-123 mit auf dem Spitzende aufgezogenem Gleitmantel)

| (Bild: Werkseitig integrierte, gekammerte Dichtungssysteme [FI-Forsh] - F-113 selbstschmierende Dichtung)

|

|

|

|

(Bild: Fugenverguss mit Gießring - Gießring mit Vergussöffnung [Müche65])

|

(Bild: Fugenverguss mit Gießring - Anlegen des Gießringes um die Muffe [Müche65])

|

(Bild: Fugenverguss mit Gießring - Geschlossener Gießring [Müche65])

|

|

(Bild: Fugenverguss mit Gießring - Einfüllen der Vergussmasse [Müche65])

|

(Bild: Fugenverguss mit Gießring - Dichtung nach Entfernen des Gießringes [Müche65])

|

|

|

|

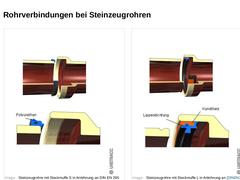

| (Bild: Steinzeugrohre mit Steckmuffe S in Anlehnung an DIN EN 295 [DINEN295a])

| (Bild: Steinzeugrohre mit Steckmuffe L in Anlehnung an [DINEN295a])

|

|

|

| (Bild: Adapterkupplung zur flexiblen Spitzendverbindung unterschiedlicher Rohrwerkstoffe und verschiedener Nennweiten im Außendurchmesser von 35 bis 420mm) | | (Bild: Manschettendichtung zur Verbindung zweier Spitzenden; bspw. Beim nachträglichen Einbau von Abzweigen oder beim Auswechseln von Steinzeugrohren) | (Bild: Passring als Dichtlement für das Spitzende von gekürzten Rohren und Formstücken aus Steinzeug) |

|

|

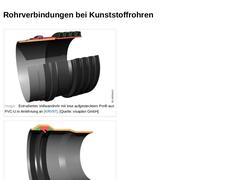

| (Bild: Extrudiertes Vollwandrohr mit lose aufgestecktem Profil aus PVC-U in Anlehnung an [KRV97]) | | (Bild: Rohrverbindung eines Vollwandrohres aus PVC-U mit werksseitig eingebautem Dichtring in Anlehnung an [DIN19534]) |

|

|

|

|

Als Muffenverbindung für Rohre aus duktilem Gußeisen nach DIN 28603 [DIN28603:1982] wurde in der Bundesrepublik Deutschland im Jahre 1957 die Tyton-Verbindung eingeführt. Sie hat einen eng tolerierten Zentrierbund zur Verhinderung von Dezentrierbewegungen. Die Abdichtung, die durch einen besonders profilierten Dichtring erreicht wird , besteht aus einer härteren und einer weicheren Gummimischung. |

(Bild: Steckmuffen-Verbindung System Tyton nach … |

|

|

|

Die Tyton-Verbindung kann auch als längskraftschlüssige Verbindung ausgebildet werden. Dazu wird auf den Spitzenden ein Schweißwulst aufgebracht. Dies geschieht normalerweise werkseitig durch eine Auftragsschweißung unter Schutzgas, kann aber auch bei abgeschnittenen Rohren auf der Baustelle elektrisch erfolgen. Nach dem Zusammenschieben der Rohre wird ein Verriegelungselement durch eine werkseitig ausgeführte Aussparung in der Steckmuffe in den … |

|

|

|

|

|

(Bild: Schächte) |

Unter Schacht versteht man nach DIN EN 752 [DINEN752:2008] einen "Einstieg mit abnehmbarem Deckel, angebracht auf einer Abwasserleitung oder einem Abwasserkanal, um den Einstieg von Personen zu ermöglichen." |

|

|

|

(Bild: Funktion von Schächten - Zugänglichkeit - Zugang für Personen) |

Schächte werden nach DIN EN 476 [DINEN476:1997] auch als Einsteigschacht bezeichnet und wie folgt unterschieden:

Einsteigschächte mit Zugang für Personal

"Einsteigschächte mit Zugang für Personal müssen für alle Instandhaltungsarbeiten am System geeignet sein. Die Nennweite muss DN/ID 1000 oder mehr, für Rechteckquerschnitte 750 x 1200 oder mehr und für elliptische Querschnitte … |

|

|

|

Einsteigschächte mit gelegentlichem Zugang zur Reinigung und Inspektion:

"Einsteigschächte zum Einbringen von Reinigungsgerät, Inspektions- und Prüfausrüstung mit gelegentlicher Zugangsmöglichkeit für eine angegurtete Person müssen eine Nennweite von DN/ID 800 oder mehr, aber weniger als DN/ID 1000 haben" [DINEN476:1997]. | | (Bild: HS®-Kontrollschacht Typ 2 mit BEGU-Abdeckung Kl. B, Sohltiefe von min. 1430 mm bis max. 2930 mm, verschiedene Steigrohrlängen … |

|

|

|

(Bild: Gemauerter Schacht) |

|

(Bild: Schachtbauwerk aus Ortbeton) |

Schächte wurden früher vornehmlich gemauert , in Ortbeton oder aus Fertigteilen aus Beton und Stahlbeton hergestellt.

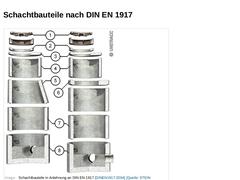

Den Stand der Technik der heute vornehmlich eingesetzten, vorgefertigten Schächte bzw. Schachtfertigteile aus Beton und Stahlbeton dokumentiert die DIN 4034 Teil 1 [DIN4034-1:1993]. Auf europäischer Ebene ist die CEN-N 393E [CENN393] zu beachten, deren Anwendungsbereich … |

|

|

|

Heute stehen Schächte aus fast allen Werkstoffen zur Verfügung. Ausnahmen bilden lediglich Stahl und Gusseisen. |

(Bild: Schacht aus PE-HD (DN 3000, H = 6000 mm) [FI-Kunstb]) |

(Bild: Schachtunterteile aus Steinzeug [FI-Stein]) |

|

|

|

| (Bild: Schachtbauteile in Anlehnung an DIN EN 1917 [DINEN1917a] [Bild: S&P GmbH]) |

|

|

| (Bild: Aufbau eines Schachts)

| |

(Bild: Unterfütterung des Rahmens der Schachtabdeckung mit Gußasphalt)

|

(Bild: Höhenverstellbare Schachtabdeckung mit Federelement)

|

(Bild: Schnitt durch eine Schachtabdeckung bei Einbettung in die Tragschicht und Umpflasterung mit Spezial-Formsteinen in Anlehnung an [FI-Schwab])

|

1) | |

(Bild: Blick in den gereinigten Startschacht)

|

(Bild: Blick in den geöffnetet Schacht)

|

(Bild: Steigleiter)

|

2) | |

|

|

|

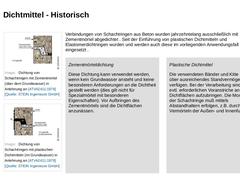

(Bild: Dichtung von Schachtringen mit Zementmörtel (über dem Grundwasser) in Anlehnung an [ATVA241a] [Bild: S&P GmbH])

|

|

(Bild: Dichtung von Schachtringen mit plastischen Dichtmitteln (im Grundwasser) in Anlehnung an [ATVA241a] [Bild: S&P GmbH])

|

|

Verbindungen von Schachtringen aus Beton wurden jahrzehntelang ausschließlich mit Zementmörtel abgedichtet . Seit der Einführung von plastischen Dichtmitteln und Elastomerdichtringen wurden und werden … |

|

|

|

Nach ATV-DVWK-A 157 [ATVA157:2000] werden aktuell ausschließlich Dichtmittel aus Elastomeren nach DIN EN 681 [DINEN681:2001] und DIN 4060 [DIN4060:1998] zur Abdichtung der Fugen zwischen Schachtfertigteilen gefordert. |

(Bild: Schachtringdichtungen aus Elastomeren in Anlehnung an [FI-Denso] - Dichtring mit dichter Struktur für Spitzenden nach DIN 4034-1)

|

(Bild: Schachtringdichtungen aus Elastomeren in Anlehnung an [FI-Denso] - Dichtring mit angeformtem … |

|

|

|

|

Nach DIN EN 1917 [DINEN1917:2004] sind auch andere Dichtmittel zulässig, dennoch müssen auch diese die werkseitigen Dichtheitskriterien erfüllen. | (Bild: Bauteilverbindungen nach DIN EN 1917 [DINEN1917a] - Elastomerdichtung)

| | (Bild: Bauteilverbindungen nach DIN EN 1917 [DINEN1917a] - Elastomeres, plastomeres oder anderes Dichtmittel)

| (Bild: Bauteilverbindungen nach DIN EN 1917 [DINEN1917a] - Elastomeres, plastomeres oder anderes Dichtmittel)

… |

|

|

|

|

Der Vortrag behandelt die im Entwässerungssystem vorkommende Bauteile und Werkstoffe. |

|

Mit der industriellen Entwicklung zu Beginn des 19. Jahrhunderts erwuchs insbesondere in den großen Städten Deutschlands auch die Notwendigkeit zum Bau von Kanalisationen, d.h. von Anlagen zur Sammlung und Ableitung von Abwasser. Diese wurden seitdem ständig erweitert und stellen heute teilweise die größte Vermögensanlage von Städten, Gemeinden oder Entwässerungswerken dar. Die vorliegende Vortragsreihe" Aufbau und Randbedingungen von Kanalisationen" |

|

| (Bild: Überblick über unterirdische Infrastrukturen in der Gegenwart)

|

|