|

The jacking performance of microtunnelling with pneumatic spoil removal is subject to the following influence: -

subsoil conditions and type of soil (cohesive, non-cohesive)

-

jacking distance

-

jacking technology (design of the cutting head)

-

number and qualification of the personnel (especially the experience of the machine operator)

-

construction-site-specific boundary conditions (e.g. space)

-

jacking pipe (nominal pipe size, material, quality)

|

|

|

(Image: Pros and cons)

(Table: Advantages and disadvantages of microtunnelling with pneumatic spoil removal) |

|

|

|

|

|

(Image: Microtunnelling with spoil removal by other mechanical means (spoil removal by a scraper arrangement)) |

Method of operation and procedure

Microtunnelling with scraper spoil removal is marked by pipe jacking with the simultaneous excavation of soil at the work face by means of a cutting head and continuous or discontinuous soil removal with a scraper arrangement.

One representative of this group is the Swedish LUNDBY method [FI-Skansb]. |

|

|

Nowadays this method, which was originally developed for the nominal size range from DN/ID 400 (16 in), is only used in the nominal size range 800 ≤ DN/ID ≤ 2750 (32 in to 108 in) (from a clear width > 1200 mm (48 in) referred to as manned pipe jacking). It is therefore ideally suitable for very soft, cohesive clay with a clay concentration of ≥ 40% and one-axial uniaxial compressive strengths ≤ 0.05 N/mm2. (Image: Conveying of soil with the LUNDBY … |

|

|

Area of application of the LUNDBY method: -

nominal pipe size range from DN/ID 800 (32 in) up to a clear width < 2750 mm (108 in) and a jacking distance ≤ 150 m (492 ft)

-

usually straight bores; cohesive, saturated soil of classes LBM 1/LBO 1 with N-values ≤ 4

|

|

(Image: Attention!)

Empirical value for the jacking performance in the LUNDBY method: 1.25 to 4.2 m/h |

|

|

|

|

|

(Image: Microtunnelling with soil displacement) |

Method of operation and procedure The group of microtunnelling with spoil displacement is characterized by the single-phase jacking of pipes with simultaneous displacement of the soil by means of a displacement and steering head, e.g. no system for removing the soil is provided. The method of operation and equipment of the single-phase microtunnelling method with soil displacement are basically identical … |

|

|

|

Microtunnelling methods with soil displacement are used exclusively in displaceable soils with or without groundwater. (Table: Areas of application of microtunnelling methods with soil displacement according to the manufacturer's information) |

|

|

|

|

This presentation is part of the series of presentations "Utility Tunnelling" and deals with microtunnelling.

|

|

Today, supply and discharge lines are still predominantly installed by using the open-cut method: a trench is dug, the lines are installed under the protection of an embankment or sheeting and the trench is filled afterwards. In the face of the numerous disadvantages as well as the citizens' growing environmental consciousness in the future it is urgently necessary to take trenchless technology into account much stronger than until today as an alternative … |

|

|

(Image: Overview of the present underground infrastructures) |

A prerequisite for the functionality of human community and urban further development are efficient line networks that ensure a reliable supply with water, gas, district heating, electricity and telecommunication as well as an environmentally friendly disposal, i.e. collection and discharge of the sewage. |

|

|

|

|

Trenchless construction technique:

Any technique for constructing pipelines in the ground without opening trenches [DINEN12889:2000]. |

|

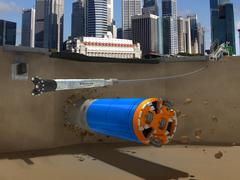

(Image: Shield machine arriving in the target shaft) |

|

(Image: Microtunnelling machine with pneumatic spoil removal (method AVP [FI-Herreb]) - Scraper cutting head with view of the rotary vane lock behind the excavation chamber) |

|

(Image: Microtunnelling machine with auger spoil removal ? cutting head) |

|

|

|

Underground … |

|

|

|

|

| (Image: Manned techniques)

manned | (Image: Unmanned techniques)

unmanned | | (Image: Steerable techniques)

steerable | (Image: Steerable techniques)

steerable | (Image: Non-steerable techniques)

non-steerable | | (Image: Soil removal techniques)

soil removal | (Image: Soil removal techniques)

soil removal | (Image: Soil displacement techniques)

soil displacement | (Image: Soil removal techniques)

soil removal | (Image: Soil displacement techniques)

soil displacement… |

|

|

|

(Image: Manned techniques) Manned technique:

Technique involving the use of personnel working in the excavated bore during installation [DINEN12889:2000]. |

|

|

|

(Image: Unmanned techniques) Unmanned technique:

Technique avoiding the use of personnel working in the excavated bore during installation [DINEN12889:2000]. |

|

|

|

(Image: Steerable techniques)

Steerable techniques:

Techniques which allow for a correction of the direction of the cutting head, the steel pipe joint or auger flight [Stein05a]. |

|

|

|

(Image: Non-steerable techniques)

Non-steerable techniques:

Techniques which do not allow for a correction of the direction of the cutting head, the steel pipe joint or auger flight [Stein05a]. |

|

|

|

(Image: Soil removal techniques)

Soil removal techniques:

Jacking pipes are jacked either dynamically or statically from a starting shaft to a target shaft whereby the soil or rock material loosened by the jacking is transported away either continuously, in intervals or after the boring [Stein05a]. |

|

|

|

(Image: Soil displacement techniques)

Soil displacement techniques:

Static or dynamic jacking of jacking pipes by displacement of the in situ soil … |

|

|

|

(Image: Overview of the methods of trenchless installation of cables and pipelines by jacking or drilling) |

|

|

|

|

|

(Image: Pros and cons)

Advantages of trenchless construction: -

groundwater lowering not necessary

-

relatively small excavated soil volume

-

only in the region of the starting and target pits road breaking necessary

-

low impact of traffic and thus less traffic jams and strain of residents due to exhaust fumes

-

less damage of neighbouring structures

|

(Image: Pros and cons)

Disadvantage of trenchless technology: -

possibly higher costs with reference …

|

|

|

|

|

This presentation is part of the series of presentations "Utility Tunnelling" and intends to give an extensive introduction to the topic of trenchless technologies. |