|

In the context of the inspection and acceptance of rehabilitated locally limited areas of damage in man-accessible sewers (e.g. cracks before and after sealing by means of injection), it can make sense to carry out leak tightness testing only in the affected areas. A suitable, tried and tested testing device is shown in Image 4‑166. (Image: Device used for leak tightness testing’s of locally limited areas of damage in man-accessible sewers ) It is … |

|

Regarding the inspection of newly laid or recently rehabilitated manholes and inspection chambers and their pipe connections EN 1610 [ [DINEN1610: 2015]] applies in Europe and DWA-A 139 [ [DWAA139:2019]] in Germany. The inspection itself is solely based on water as the test medium. This results from the fact that it is impossible to define conditions for testing with either air or vacuum that have the same leak tightness requirements for manholes … |

|

Testing of road catch basins At the current time, there are still no rules and regulations for leak tightness testing in road catch basins (section 1.6). The following remarks are based on the results of a research project that has been carried out in 2008 on behalf of the Stiftung Industry research centre (Cologne) [ [Stein2008]] with the target to close that gap. The test methods and criteria that are determined in the standard regulations for drains, … |

|

Basically, leak tightness testing for connection sewers is comparable to that for drains and sewers ( (Leak tightness testing of drains and sewers – Testing along entire sections)). Tests can be done either with air or water. The type of the test medium to be used is determined by the client. Due to the generally large difference in height between the lowest and the highest point of the individual pipe, the test should preferably be carried out with … |

|

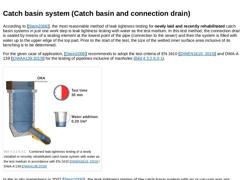

According to [ [Stein2008]], the most reasonable method of leak tightness testing for newly laid and recently rehabilitated catch basin systems in just one work step is leak tightness testing with water as the test medium. In this test method, the connection drain is sealed by means of a sealing element at the lowest point of the pipe (connection to the sewer) and then the system is filled with water up to the upper edge of the top part. Prior to … |

|

|

|

Each leak tightness test is to be documented in situ in a test report (test record) that is to be signed by the individual supervisor. The test report has to include all important information in an exact and comprehensive form.. The test report is to be created separately for each testing. It should always include: -

Object-related data

-

Client, contractor, project manager (where applicable), machine operator, location to be tested, street name, sewer …

|

|

|

|

Localising leaks The standard test methods of leak tightness testing with water, air or vacuum as the test media are very time-consuming and only allow for limited statements on the number and position of leakages. Generally, the localisation of visually perceivable leaks in the case of a failed leak tightness test is done by means of a visual inspection from inside. In the methodical localisation of leaks that cannot be visually perceived, the testing … |

|

For years, acoustic leak localisation systems have been successfully in use in the water supply sector. Acoustic leak localisation is a simple test method with only some equipment needed to localise leakages either by listening to the sewers for flow sounds via hydrophones [ [FI-Sewera]] or according to the correlation method [ [FI-Sewera]] [ [Fromm87]] [ [Riehl87]] in combination with a leak tightness testing that uses air as the test medium. In … |

|

A system that is already available in practice and counts among this group of methods to localise leakages in sewers is the sewage probe AMS-4 [ [FI-seba]] [ [Schub98]] [ [Kramp98]][ [Kreut94]] manufactured by the company Seba Dynatronic [ [Stein03b]]. The sewage probe AMS-4 makes use of the conductivity of (waste)water to determine and localise leakages. It is composed of a steel cylinder with an electrode and a coupled data converter. After the … |

|

Since the 1980s, infrared thermography has represented a method for a damage-free localisation of leaks during external and/or internal inspection [ [Natut97]]. Basically, every solid figure transmits long wavelength radiation that falls in the infrared region of the electromagnetic wave spectrum. This covers wave lengths from 0.7 to 1,000 μm. As each solid figure acts as an emitter of long wave radiation and not only as a reflector, as it is the … |

|

|

|

|

|

To solve hydraulic problems, it is required to collect and assess all relevant information to evaluate the individual situation. A calculation of the dry and storm weather flows, amended by an inventory of faulty connections and leakages, is often not sufficient to describe the hydraulic loads on the sewers in a comprehensive way. The actual flow in a drain and sewer network section can significantly differ from the results of hydraulic calculations … |

|

The planning of a flow measurement requires expert knowledge and experience in the field of hydrometrics and always has to be adjusted individually to the given task as well as the structural and hydraulic conditions in situ. The manufacturers’ catalogues of numerous portable flow measurement devices promise an easy handling and a universal application spectrum for each hydraulic problem. In fact, portable measurement systems that are based on the … |

|

Depending on the individual target of a flow measurement, a number of different hydraulic situations will occur in the cross section to be measured. Not all methods of measurement and certainly not all measurement devices are equally suitable for that purpose. In the case that data are to be gathered on the hydraulic loading and capacities of the sewer, a large bandwidth of flow conditions up to a possibly complete filling under excess flow conditions … |

|

The selection of the site of measurement is decisive for the result of a flow measurement. Methods of measurement and measuring devices, which, because of the system, have a guaranteed rate of error of no more than a few percentage points can generate operating errors of more than 20 per cent when the required hydraulic conditions are not fulfilled at the chosen site of measurement. The most accurate measuring results require a backwater-free measuring … |

|

Time of measurement The appropriate time for a flow measurement also depends on its purpose. The measurement has to take place preferably at a point in time that allows for an isolated observation of the flow in the sewer section of interest, undisturbed by other flow sources. Investigations to determine the extraneous water share caused by infiltrating groundwater are carried out at about 2 a.m. on a dry night, for example. At this time, the flow … |

|

Measuring Procedure Flow measurements carried out in the sewage field are rarely direct measurements. In fact, the volume flow through a certain cross section is derived from variables that are easier to measure and proportional to the volume flow. Measurements in a gravity open channel with known dimensions do normally require two variables to determine the volume flow: the depth of flow h and the mean flow velocity vm. From these variables the volume … |

|

The measurement methods described in the following section differ from the previously introduced methods for two reasons: Structures are always required in the open channel profile, which sometimes substantially reduce the hydraulic capability of the sewer section and can thus create backwater. Consequently, these methods cannot be used for all tasks at hand. Besides this rather practical point of view, a characteristic feature that is shared by … |

|

|

|

|

|

Transducer and measuring instruments Various transducers or measuring instruments are necessary in order to acquire the measuring information required by the methods of measurement described above. According to DIN 19559-1 [ [DIN19559-1:1983]], these should be “robust and low-maintenance” and measure “without any extra impairment of the flow cross section with a high degree of flow constancy, uninfluenced by extreme environment-related conditions, … |

|

Flow velocity measurement Flow velocity measurement may relate to the velocity of a flow. Direct measurement of mean flow velocity – Magnetic inductive velocity sensors and through flow measurement devices (MID) MID-transducers rely on the electrical conductivity of the sewage. The basis of this measurement principle is Faraday´s law of induction: a voltage is induced in a conductor that is positioned at right angle to the lines … |