|

Grundsätzlich gilt nach DIN 4124:

„[…] Baugruben und Gräben sind so abzuböschen, zu verbauen oder anderweitig zu sichern, dass sie während der einzelnen Bauzustände standsicher sind. Dabei sind alle Gegebenheiten und Einflüsse, welche die Standsicherheit der Baugruben- bzw. Grabenwände beeinträchtigen können, zu berücksichtigen, insbesondere das unterschiedliche Verhalten von nichtbindigen und bindigen Böden […].“ |

|

Während der Aushubarbeiten ist zu prüfen, ob der tatsächlich angetroffene Boden mit den Annahmen in der Rohrstatik übereinstimmt (z. B. durch geotechnische Erkundung und Untersuchung). Bei Abweichungen ist unbedingt der Bauüberwacher bzw. der Statiker zu informieren. (Bild: Grabenaushub mit Raupenbagger) |

|

Im innerstädtischen Bereich sind vorhandene Rohrleitungen und Kabel zu berücksichtigen. Im Zweifelsfall ist es sinnvoll, Suchschachtungen von Hand auszuführen, da die tatsächliche Lage der Leitungen sehr häufig von den Planunterlagen abweicht. Angetroffene Leitungen sind in Abstimmung mit den Leitungsbetreibern durch Aufhängen, Abstützen, Umlegen etc. zu sichern. (Bild: Leitungs- und Kabelsituation im innerstädtischen Bereich) (Bild: Suchschachtung … |

|

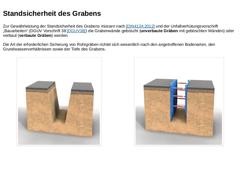

Zur Gewährleistung der Standsicherheit des Grabens müssen nach [DIN4124:2012] und der Unfallverhütungsvorschrift „Bauarbeiten“ (DGUV Vorschrift 38 [DGUV38]) die Grabenwände geböscht (unverbaute Gräben mit geböschten Wänden) oder verbaut (verbaute Gräben) werden. Die Art der erforderlichen Sicherung von Rohrgräben richtet sich wesentlich nach den angetroffenen Bodenarten, den Grundwasserverhältnissen sowie der Tiefe des Grabens. (Bild: Unverbauter Graben – … |

|

Zur Beurteilung der Standsicherheit des Grabens sind im Allgemeinen folgende Angaben und Unterlagen nach DIN 4124 erforderlich: -

Maße des Grabens

-

Einstufung in eine geotechnische Kategorie nach DIN 1054 im Hinblick auf Baugrund und Bauausführung

-

Baugrundverhältnisse, Bodenschichtung, Ergebnisse bodenmechanischer Versuche, Grundwasserverhältnisse im Rahmen eines geotechnischen Berichts nach DIN 4020

-

Gründungstiefe, Fundamentausbildung und Abstand …

|

|

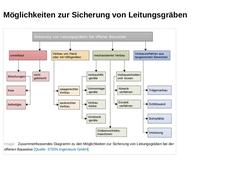

(Bild: Zusammenfassendes Diagramm zu den Möglichkeiten zur Sicherung von Leitungsgräben bei der offenen Bauweise) |

|

|

|

Baugruben und Gräben bis 1,25 m Tiefe dürfen nach DIN 4124 ohne Sicherung mit senkrechten Wänden hergestellt werden, wenn mindestens steifer bindiger Boden ansteht und die angrenzende Geländeoberfläche… [DIN4124:2012] (Bild: Sicherung von Gräben und Schächten ohne Verbau bei Tiefen ≤ 1.25 m – senkrecht geböschte … |

|

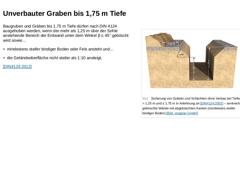

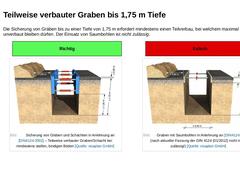

(Bild: Sicherung von Gräben und Schächten ohne Verbau bei Tiefen > 1.25 m und ≤ 1.75 m in Anlehnung an [DIN4124c] – senkrecht geböschte Wände mit abgeböschten Kanten (mindestens steifer bindiger Boden) [Illustration: visaplan GmbH]) Baugruben und Gräben bis 1,75 m Tiefe dürfen nach DIN 4124 ausgehoben werden, wenn der mehr als 1,25 m über der Sohle anstehende Bereich der Erdwand unter dem Winkel β ≤ 45° geböscht wird sowie… |

|

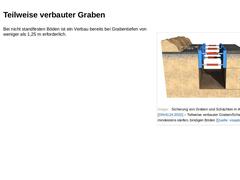

(Bild: Sicherung von Gräben und Schächten in Anlehnung an [DIN4124c] - Teilweise verbauter Graben/Schacht bei mindestens steifen, bindigen Böden [Illustration: visaplan GmbH]) Bei nicht standfesten Böden ist ein Verbau bereits bei Grabentiefen von weniger als 1,25 m erforderlich. |

|

Die Sicherung von Gräben bis zu einer Tiefe von 1,75 m erfordert mindestens einen Teilverbau, bei welchem maximal 1,25 m unverbaut bleiben dürfen. Der Einsatz von Saumbohlen ist nicht zulässig. (Bild: Sicherung von Gräben und Schächten in Anlehnung an [DIN4124c] - Teilweise verbauter Graben/Schacht bei mindestens steifen, bindigen Böden [Illustration: visaplan GmbH]) (Bild: Graben mit Saumbohlen in Anlehnung an [DIN4124a] (nach aktueller … |

|

Bei Tiefen von mehr als 1,75 m ist ein vollflächiger Verbau oder die Ausbildung von geböschten Grabenwänden unter Beachtung des von der Bodenart abhängigen zulässigen Böschungswinkels notwendig.

Es ist zu beachten, dass auch die Stirnwände der Gräben durch Böschungen oder Verbau zu sichern sind. Lediglich bei Gräben bis zu einer Tiefe von 1,75 m, einer Breite bis zu 1,25 m und in mindestens steifem bindigem Boden kann auf diese verzichtet werden.… |

|

(Bild: Böschungswinkel und Arbeitsraumbreite nach DWA-A 139) (Bild: Unverbauter Graben mit einem Böschungswinkel von β = 45° und Mindestabstand zur Grabenkante) Der Böschungswinkel richtet sich nach dem Baugrund (physikalische Eigenschaften der anstehenden Bodenarten, Wasserverhältnisse), der Nutzung angrenzender Flächen (Verkehrswege, Bebauung), den zu erwartenden Beanspruchungen durch Baugeräte, der Höhe der Böschung und ihrer voraussichtlichen … |

|

(Bild: Unverbauter Graben im Fels - ein erforderlicher Böschungswinkel von β= 80° wird nicht eingehalten) (Bild: Unverbauter Graben in nichtbindigen und weichen Böden mit einem Böschungswinkel von β = 45°) Ohne rechnerischen Nachweis dürfen folgende Böschungswinkel in Anlehnung an die DIN 4124 nicht überschritten werden: β = 45° bei nichtbindigen und weichen bindigen Böden

β = 60° bei mindestens steifen bindigen Böden

β = 80° bei Fels |

|

Die Angaben für Grabentiefen und Böschungswinkel von unverbauten Gräben gelten nur, wenn… -

die Mindestabstände von Fahrzeugen und Baugeräten zur Böschungskante eingehalten werden.

-

keine, die Standsicherheit gefährdende, ungünstige Gegebenheit und kein ungünstiger Einfluss vorliegen, wie beispielsweise durch -

Störungen des Bodengefüges (Klüfte oder Verwerfungen)

-

zum Graben einfallende Schichtung/Schieferung

-

Zufluss von Schichtenwasser

-

vorhandene …

|

|

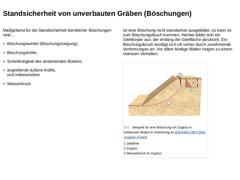

Maßgebend für die Standsicherheit künstlicher Böschungen sind… -

Böschungswinkel (Böschungsneigung),

-

Böschungshöhe,

-

Scherfestigkeit des anstehenden Bodens,

-

angreifende äußere Kräfte,

und insbesondere

-

Wasserdruck.

Ist eine Böschung nicht standsicher ausgebildet, so kann es zum Böschungsbruch kommen. Hierbei bildet sich ein Gleitkörper aus, der entlang der Gleitfläche abrutscht. Ein Böschungsbruch kündigt sich oft vorher durch zunehmende Verformungen … |

|

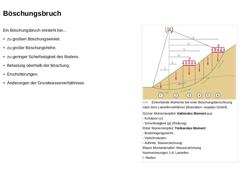

Ein Böschungsbruch entsteht bei… -

zu großem Böschungswinkel.

-

zu großer Böschungshöhe.

-

zu geringer Scherfestigkeit des Bodens.

-

Belastung oberhalb der Böschung.

-

Erschütterungen.

-

Änderungen der Grundwasserverhältnisse.

(Bild: Einwirkende Momente bei einer Böschungsberechnung nach dem Lamellenverfahren) |

|

(Bild: Nicht verbauter Graben mit einer Tiefe > 1,25 m = Lebensgefahr! (und Nicht-Einhaltung von Arbeitssicherheitsvorschriften)) (Bild: Nur partiell verbauter Graben mit einer Tiefe > 1,25 m Tiefe = Lebensgefahr!) Bei Abweichung von den "Standard-Randbedingungen" ist die Standsicherheit geböschter Wände nach nach DIN EN 1997-1, DIN 1054 bzw. DIN 4084 oder ein Sachverständigengutachten nachzuweisen. Böschungen müssen hinsichtlich ihrer Standsicherheit … |

|

|

|

Die Wahl des Verbaus richtet sich nach den örtlichen Randbedingungen (wie z. B. Bodenart, Grundwasserstand, Abmessungen des Grabens, Anzahl von Zuläufen und kreuzenden Leitungen, Beschaffenheit der angrenzenden Flächen oder zu erwartende Beanspruchungen durch Baugeräte).

Zur Auswahl und eventuellen Bemessung eines Grabenverbaus müssen daher mindestens folgende Daten bekannt sein: |

|

Die Art des Verbausystems wird in der Rohrstatik berücksichtigt und darf ohne Abstimmung mit dem Statiker nicht verändert werden. |

|

Überwiegend eingesetzte Verbauarten sind: Die hier aufgeführte Verbauarten zählen zu den "weichen Verbauarten", d. h. je nach Tiefe müssen in gewissen Abständen Rückverankerungen oder Versteifungen eingesetzt werden. Zu den steifen Verbauarten zählen Bohrpfahlwände und Schlitzwände, die bei setzungsempfindlichem … |

|

Der waagerechte Normverbau kann in grundwasserfreiem Baugrund je nach Bohlendicke bis zu Schachttiefen von 5,0 m eingesetzt werden. Hier werden nach DIN 4124 die Schachtwände mit dem Aushub fortschreitend von oben nach unten mit waagerechten, dicht aneinander liegenden Holzbohlen, Kanaldielen oder dergleichen verkleidet, die in der Regel mittels lotrechter Brusthölzer gesichert und durch Steifen abgestützt werden [DIN4124:2012]. |

|

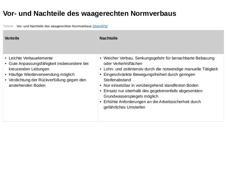

(Tabelle: Vor- und Nachteile des waagerechten Normverbaus [Stein97b]) |

|

Beim senkrechten Normverbau nach DIN 4124 werden Holzbohlen oder Kanaldielen mit dem Aushub fortschreitend eingebaut oder in weichen, bindigen Lockergesteinen vorab senkrecht in den Boden eingetrieben, so dass sie in jedem Bauzustand mit ihrer Spitze mindestens 0,30 m im Boden stecken [DIN4124:2012]. (Bild: Beispiel für eine Kanaldiele – Kanaldiele KD 600/8 (Profilbreite 600 mm und Profilhöhe 80 mm)) Die auf die senkrechten Holzbohlen oder Kanaldielen … |