|

In accordance with DWA-M 168, concrete pipes (made from "normal concrete") are considered to have sufficient corrosion resistance when: -

a permanent loading of inorganic and organic acids does not fall bellow a pH value 6.5.

-

a temporary loading (up to one year for every ten years) with inorganic acids, with a pH of not less than 5.5 (for organic acids not less than pH = 6.0).

-

a short-term loading (maximum of one hour per week) by inorganic and organic …

|

|

The advantages of various materials are combined in concrete and reinforced concrete pipes with a corrosion protection applied directly during the production of the pipes for use in sewer systems with unavoidable and constantly "very strong" chemical aggressors according to DIN 4030 and DWA-M 168. These pipes are composed of two layers, the carrier layer on the outside and the corrosion protection layer (lining or coating) on the inside [Stein82b] [… |

|

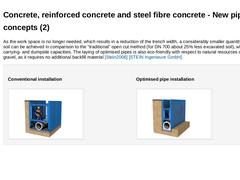

The latest development in the field of concrete- and reinforced concrete pipes is the “Optimised Pipe” for the nominal size range DN 500 to DN 1,200, which has an optimised outer contour with regard to structural and engineering factors. Pipe laying is facilitated because of the smooth bottom surface of the pipe and a gap in its centre. As the side walls are vertical, the difficult procedure to compact the spaces either side of the bottom half of … |

|

As the work space is no longer needed, which results in a reduction of the trench width, a considerably smaller quantity of excavated soil can be achieved in comparison to the “traditional” open cut method (for DN 700 about 25% less excavated soil), which saves carrying- and dumpsite capacities. The laying of optimised pipes is also eco-friendly with respect to natural resources of sand and gravel, as it requires no additional backfill material [… |

|

Polymer concrete consists of a mixture of mineral, quartzite fillers in the minimally porous grading curve range according to DIN 1045, and reaction resin based on unsaturated polyester resins with properties according to DIN 16946 Part 2, Table 3. The polyester resin is very resistant to aggressive media (pH range 1.0 to 10) and the quartz aggregates are not chemically vulnerable. Since the material microstructure is free of capillaries, it does … |

|

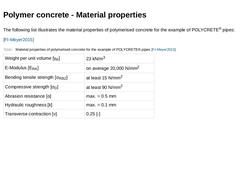

The following list illustrates the material properties of polymerised concrete for the example of POLYCRETE® pipes: [FI-Meyer2015] (Table: Material properties of polymerised concrete for the example of POLYCRETE® pipes) |

|

Polymer concrete pipes are suitable for laying in the open cut- as well as trenchless method of construction. POLYCRETE® pipes for the open cut method are produced with circular cross section and bell socket from DN 300 to DN 1,000; with rebate joint from DN 1,200 to DN 2,000 as well as with ovoid cross section according to DIN 4263 in the nominal size range b/h of 400/600 to 1,400/2,100 [FI-Meyerb]. The bell socket has a rigidly inserted sealing medium; … |

|

Cast basalt is created by melting non-metallic components at 2000°C and by their subsequent crystallization. The final product is a three-phase system consisting of corundum, baddeleyite and glass phase with a very smooth surface. These minerals give the cast basalt a high compressive strength and especially great hardness (Mohs' hardness 8) and resistance to high temperatures, corrosion and abrasion. Cast basalt pipes are created in the centrifugal … |

|

|

|

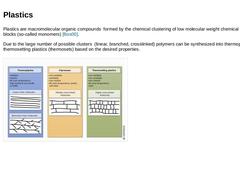

Plastics are macromolecular organic compounds formed by the chemical clustering of low molecular weight chemical building blocks (so-called monomers) [Bos00]. Due to the large number of possible clusters (linear, branched, crosslinked) polymers can be synthesized into thermoplastics and thermosetting plastics (thermosets) based on the desired properties. (Image: Schematic view of the arrangement of the chain molecules in plastics and their properties … |

|

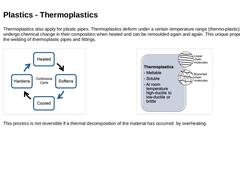

Thermoplastics also apply for plastic pipes. Thermoplastics deform under a certain temperature range (thermo-plastic). They do not undergo chemical change in their composition when heated and can be remoulded again and again. This unique property enables the welding of thermoplastic pipes and fittings. (Image: Heating and cooling cycle of thermoplastic) (Image: Structure of thermoplastics) This process is not reversible if a thermal decomposition of … |

|

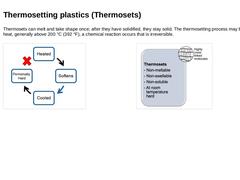

Thermosets can melt and take shape once; after they have solidified, they stay solid. The thermosetting process may be induced by heat, generally above 200 °C (392 °F), a chemical reaction occurs that is irreversible. (Image: Heating and cooling cycle of thermosetting plastic) (Image: Structure of thermosets) |

|

Thermoplastics are constructed from small or non-branched (i.e. linear) hydrocarbon chains, which are connected to one another by a weak physical bonds.These binding forces are more effective when the chains are aligned in parallel. Such regions are called crystalline (red circle), and are in contrast to amorphous (disordered) regions in which the macromolecules are entangled [WikiThermoplast]. (Image: Thermoplastic chains) |

|

Important thermoplastics are: -

Polyethene (PE)

-

Polypropen (PP)

-

Polystyrene (PS)

-

Polyvinyl chloride (PVC)

-

Polyacrylonitrile (PAN)

-

Polyamides (PA)

-

Polyester (PES)

-

Polyacrylate (PAC)

For plastic sewer pipes, the following thermoplastics are used : |

|

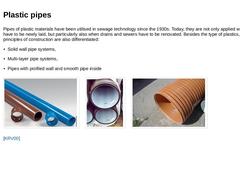

Pipes of plastic materials have been utilised in sewage technology since the 1930s. Today, they are not only applied when sewers have to be newly laid, but particularly also when drains and sewers have to be renovated. Besides the type of plastics, the following principles of construction are also differentiated: (Image: Fabekun® HS pipes - blue = … |

|

Solid wall systems are categorised into: -

Extruded single-layer systems of uPVC

-

Extruded single-layer systems of HD-PE

-

Extruded single-layer systems of PP

-

Extruded single-layer systems of PP-MD

-

Extruded two-layer systems with a light, easily-inspected internal layer of HD-PE

-

Extruded multi-layer systems with mechanical protective properties of PE (PE 100).

|

|

Scope of application The extruded single-layer systems of uPVC are manufactured in the nominal size range DN/OD 110 up to about 630 (normatively up to 1,000) and with lengths of 500, 1,000, 2,000 and 5,000 mm. The pipes are connected by means of a spigot-and-socket joint with a gasket inserted at the factory. DIN EN 1401 is valid for all uPVC pipes. [EN1401-1:2009] (Image: Pipe joint of a solid wall uPVC pipe with a sealing ring inserted at the factory … |

|

Scope of application Extruded single-layer systems of HD-PE according to DIN EN 12666 are manufactured in the nominal size range DN/OD 110 up to about 1,200 (exceptionally up to 1,600) with lengths of 5,000, 6,000 and 12,000 mm. The pipes are joined using sleeves and flanges as well as butt welding using a heating element and electrofusion welding. Connecting sleeves with sealing elements inserted at the factory are also used |

|

Scope of application According to DIN EN 12666, pipes made of extruded two-layer systems of HD-PE are manufactured in the nominal size range DN/OD 100 up to about 1,200 with lengths of 5,000, 6,000 and 12,000 mm. The pipe joints are identical with those of the extruded single-layer systems of HD-PE. [EN12666-1:2011] (Image: Two-layer system made of HD-PE with an inspection friendly light inner layer) (Image: Two-layer system made of HDPE with outer … |

|

Scope of application The extruded multi-layer systems with mechanical protective properties of PE (PE 100) according to DIN EN 12201 are principally applied for pressure- and vacuum sewerage systems. However, they are also used as gravity pipelines. The pipes are predominantly joined by means of electrofusion welding. [EN12201:2013] (Image: Solid wall pipes with an outer protective layer (protective casing) and an inspection friendly light inner layer) (… |

|

Scope of application The multi-layer systems include the co-extruded core-foamed three-layer systems of uPVC. They are subject to the approval document of the German Institute for Construction Engineering in Berlin and are manufactured in the nominal size range DN 100 to 600 with lengths of 500, 1,000, 2,000, 5,000 and 12,000 mm. The pipes are joined by means of connecting sleeves with a sealing medium inserted at the factory. DIN EN 13476 Part 2 is … |

|

According to DIN 16961, pipes with profiled wall and smooth pipe inside are “pipes with an outside profile, pipes with a dissolved section, profiled or solid wall wound pipes as well as core-foamed pipes”. -

Pipes or fittings with plain internal and external surface are according to EN 13476-1 designated as Type A

-

Pipes or fittings with plain internal surface and ripped or corrugated wall construction are according to EN 13476-1 designated as Type …

|

|

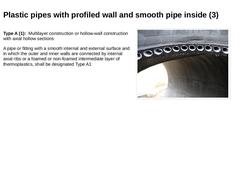

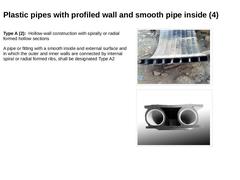

The following distinctions are made according to DIN EN 13476 Part 2 and Part 3: Type A (1): Multilayer construction or hollow-wall construction with axial hollow sections Type A (2): Hollow-wall construction with spirally or radial formed hollow sections Type B: Ripped or corrugated wall construction [EN13476-2:2007] [EN13476-3:2009] (Image: Plastic pipes with profiled wall and smooth pipe inside - Types A) (Image: Plastic pipes with profiled wall and … |

|

Type A (1): Multilayer construction or hollow-wall construction with axial hollow sections A pipe or fitting with a smooth internal and external surface and in which the outer and inner walls are connected by internal axial ribs or a foamed or non-foamed intermediate layer of thermoplastics, shall be designated Type A1 (Image: Hollow-wall construction with axial hollow sections) |

|

Type A (2): Hollow-wall construction with spirally or radial formed hollow sections A pipe or fitting with a smooth inside and external surface and in which the outer and inner walls are connected by internal spiral or radial formed ribs, shall be designated Type A2 (Image: Hollow-wall construction with spirally formed hollow, rectangular sections) (Image: Hollow-wall construction with radial formed hollow, circular sections) |