|

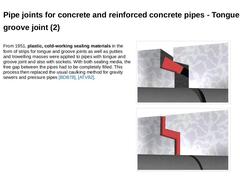

From 1951, plastic, cold-working sealing materials in the form of strips for tongue and groove joints as well as putties and trowelling masses were applied to pipes with tongue and groove joint and also with sockets. With both sealing media, the free gap between the pipes had to be completely filled. This process then replaced the usual caulking method for gravity sewers and pressure pipes [BDB78], [ATV82]. (Image: Plastic gasket band in lip-ended … |

|

(Image: Elastomer ring seal) Elastomer ring seals were not used in the sewage sector until the 1960s. Since that time, they have prevailed as sealings for spigot-and-socket joints (bell socket or lip) for pipes made of concrete, reinforced concrete, steel fibre concrete as well as other material. An elastomer is a polymer with viscoelasticity (having both viscosity and elasticity) and very weak inter-molecular forces, generally having … |

|

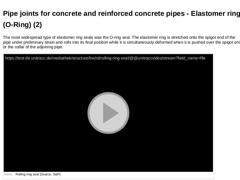

The most widespread type of elastomer ring seals was the O-ring seal. The elastomer ring is stretched onto the spigot end of the pipe under preliminary strain and rolls into its final position while it is simultaneously deformed when it is pushed over the spigot end or the collar of the adjoining pipe. (Video: Rolling ring seal) Animation: Rolling ring seal [Image: S&P GmbH]. This interactive object is only accessable in the online version of the module. |

|

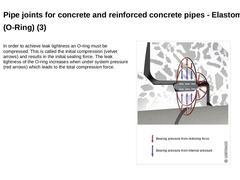

In order to achieve leak tightness an O-ring must be compressed. This is called the initial compression (velvet arrows) and results in the initial sealing force. The leak tightness of the O-ring increases when under system pressure (red arrows) which leads to the total compression force. (Image: Method of operation of an elastomer sealing ring with reference to [BDB78] [Kitte75] [Image: S&P GmbH]) |

|

Attention: According to the quality assurance guidelines in Germany, O-ring seals are no longer permitted because of their sensitivity to errors during laying. Since 1994, pipes made of concrete or reinforced concrete are exclusively produced with sealants of elastomers with a dense structure and a solid sealing cross section. Only slide ring seals are allowed that are either rigidly integrated in the socket at the factory or put … |

|

For slide ring seals, the sealing ring is stretched into its final position in a groove or is placed over the spigot end in front of the collar (also called support edge. In pushing the pipes together, the sealing ring is compressed without changing its position and thus achieves its sealing function [BDB78]. A butt joint between the pipes of 10 mm to maximally 20 mm (minimum dimension 5 mm according to DWA-A 139) permits corresponding movements of … |

|

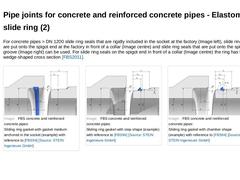

For concrete pipes > DN 1200 slide ring seals that are rigidly included in the socket at the factory (Image left), slide ring seals that are put onto the spigot end at the factory in front of a collar (Image centre) and slide ring seals that are put onto the spigot end in a groove (Image right) can be used. For slide ring seals on the spigot end in front of a collar (Image centre) the ring has to have a wedge-shaped cross section [FBS2011]. (Image: … |

|

The lip seal counts among the seals that are rigidly integrated into the socket end at the factory, as it is cemented into the socket end during pipe manufacture. Before pushing the pipes together at the construction site, the foamed material protective ring is removed and a lubricant is applied to the spigot end. The sealing of the pipe joint is achieved by the lip seal that is pressed against the spigot end when this is pushed into the socket end [… |

|

Further examples for integrated sealing elements are the gasket that is pre-lubricated at the factory and the self-lubricating gasket. The first type prevents the use of inappropriate lubricants, while the second type prevents damages at the sealing element because less insertion force is required [FI-Trelleborg2011]. (Image: One-piece pre-lubricated integrated seal for concrete pipe and manhole systems ("Forsheda 166")) |

|

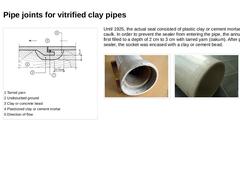

(Image: Vitrified clay pipe joint up to the start of th 20th Century [Frühl10] [Braub25]) Until 1925, the actual seal consisted of plastic clay or cement mortar or hydraulic caulk. In order to prevent the sealer from entering the pipe, the annular space was first filled to a depth of 2 cm to 3 cm with tarred yarn (oakum). After pressing in the sealer, the socket was encased with a clay or cement bead. (Image: Vitrified clay pipe joint up to the start … |

|

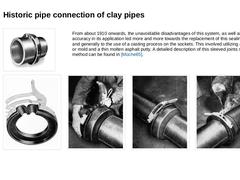

(Image: Joint grouting with cast ring sealing after removing the cast ring) From about 1910 onwards, the unavoidable disadvantages of this system, as well as the missing accuracy in its application led more and more towards the replacement of this sealing process and generally to the use of a casting process on the sockets. This involved utilizing a casting ring or mold and a thin molten asphalt putty. A detailed description of this sleeved joints … |

|

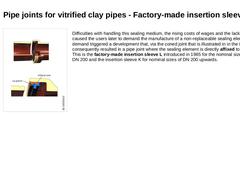

(Image: Vitrified clay pipes with socket end type L with reference to [DINEN295a] [Image: S&P GmbH]) Difficulties with handling this sealing medium, the rising costs of wages and the lack of expertise, caused the users later to demand the manufacture of a non-replaceable sealing element. This demand triggered a development that, via the coned joint that is illustrated in in the image, consequently resulted in a pipe joint where the sealing element … |

|

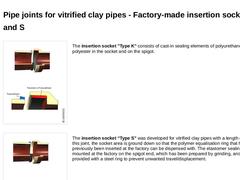

(Image: Vitrified clay pipes with socket end type K with reference to [DINEN295a] [Image: S&P GmbH]) The insertion socket "Type K" consists of cast-in sealing elements of polyurethane and polyester in the socket and on the spigot. (Image: Vitrified clay pipes with socket end type S with reference to [DINEN295a] [Image: S&P GmbH]) The insertion socket “Type S” was developed for vitrified clay pipes with a length of 2.5 m. In this joint, the socket area … |

|

(Image: Vitrified clay pipe slip-on coupling, EuroTop system [FI-EuroC]) A further development step was the introduction of pipes DN 100 to DN 300 with smooth ends (without sockets) and a flexible joint consisting of a polypropylene sleeve with two sealing profiles of elastic elastomer (slide-on coupling). The unglazed pipes without sockets are manufactured up to lengths of 2 m. |

|

Other pipe connections for clay pipes include adapter couplers and reducers as well as coupler seals. Coupler seals for nominal sizes DN 100 to DN 1400 are used to connect two spigot ends. The coupler consists of an inner rubber-elastomer sealing ring (EPDM) and an outside stainless steel shear with clamp locks. (Image: Sleeve sealing for the connection of two spigot ends; e.g. for the additional installation of branches or for the exchange of vitrified … |

|

(Image: Extruded full-wall pipe with loose PVC-U profile with reference to [KRV97] [Image: S&P GmbH]) (Image: Pipe joint of a solid wall uPVC pipe with a sealing ring inserted at the factory with reference to EN140) Elastomer seals used in plastic pipes can be installed both at the factory or directly on the construction site. The pipes are connected by means of a spigot-and-socket joint with a gasket inserted at the factory (Image at the top). DIN … |

|

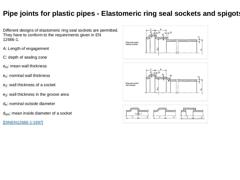

Different designs of elastomeric ring seal sockets are permitted. They have to conform to the requirements given in EN 12666-1. A: Length of engagement C: depth of sealing zone em: mean wall thickness en: nominal wall thickness e2: wall thickness of a socket e3: wall thickness in the groove area dn: nominal outside diameter dsm: mean inside diameter of a socket [DINEN12666-1:1997] (Image: Ring seal socket without chamfer)

(Image: Ring seal socket with chamfer) |

|

Welding methods for HDPE pipes: (Image: Heating element butt welding – heating element - Sketch of principle) Heating element butt welding (Image: Cross section of an electrofusion fitting) Interesting information |

|

With respect to GRP pipe joints, DIN EN 14364 classifies flexible and rigid connections. Flexible pipe joints allow for relative movements between the joint pipe components, examples for this type of jointing are: -

Jointing of socket and spigot end with an elastomer sealing element (inclusive of double socket constructions);

-

Fully restrained jointing of socket and spigot end with an elastomer sealing element (inclusive of double socket constructions);

|

|

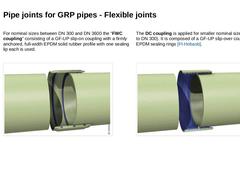

For nominal sizes between DN 300 and DN 3600 the “FWC coupling” consisting of a GF-UP slip-on coupling with a firmly anchored, full-width EPDM solid rubber profile with one sealing lip each is used. The DC coupling is applied for smaller nominal sizes (DN 150 to DN 300). It is composed of a GF-UP slip-over coupling with EPDM sealing rings [FI-Hobasb]. (Image: Jointing of GRP pipes laid by the open cut construction method with reference to [FI-Hobasb] - … |

|

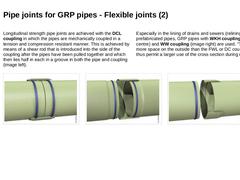

Longitudinal strength pipe joints are achieved with the DCL coupling in which the pipes are mechanically coupled in a tension and compression resistant manner. This is achieved by means of a shear rod that is introduced into the side of the coupling after the pipes have been pulled together and which then lies half in each in a groove in both the pipe and coupling (image left). Especially in the lining of drains and sewers (relining) with prefabricated … |

|

Rigid pipe joints do not allow for relative movements between the connected pipes, examples for this type of jointing are: [EN14364:2013] (Image: Jointing of GRP pipes with reference to [FI-Vetro] - Over-laminated push joint [Image: S&P GmbH]) (Image: Jointing of GRP pipes with reference to [FI-Vetro] - Socket joint, glued [… |

|

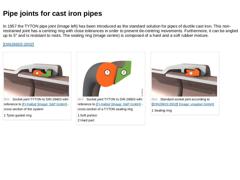

In 1957 the TYTON pipe joint (Image left) has been introduced as the standard solution for pipes of ductile cast iron. This non-restrained joint has a centring ring with close tolerances in order to prevent de-centring movements. Furthermore, it can be angled up to 5° and is resistant to roots. The sealing ring (Image centre) is composed of a hard and a soft rubber mixture. [DIN28603:2002] (Image: Socket joint TYTON to DIN 28603 - cross section of … |

|

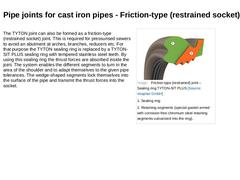

The TYTON joint can also be formed as a friction-type (restrained socket) joint. This is required for pressurised sewers to avoid an abutment at arches, branches, reducers etc. For that purpose the TYTON sealing ring is replaced by a TYTON-SIT PLUS sealing ring with tempered stainless steel teeth. By using this sealing ring the thrust forces are absorbed inside the joint. The system enables the different segments to turn in the area of the shoulder … |

|

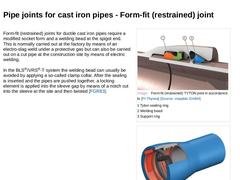

Form-fit (restrained) joints for ductile cast iron pipes require a modified socket form and a welding bead at the spigot end. This is normally carried out at the factory by means of an electro-slag weld under a protective gas but can also be carried out on a cut pipe at the construction site by means of electric welding. In the BLS®/VRS®-T system the welding bead can usually be avoided by applying a so-called clamp collar. After the sealing is inserted … |