|

|

|

Catch basin systems serve to take up the precipitation water (subsequently also called runoff or surface water) that is collected at the ground surface, enters the catch basin via gutters or troughs and is then discharged via one connection sewer/lateral each into the combined sewer for combined systems or surface water sewer for separate systems. In addition to the collection and discharge of the precipitation water, the catch basin is used for … |

|

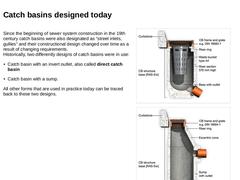

Since the beginning of sewer system construction in the 19th century catch basins were also designated as “street inlets, gullies” and their constructional design changed over time as a result of changing requirements.

Historically, two differently designs of catch basins were in use: All other forms that are used in practice today can be traced back to these … |

|

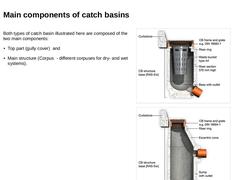

Both types of catch basin illustrated here are composed of the two main components: (Image: Catchbasin detail - direct discharge) (Image: Catch basin with sump) |

|

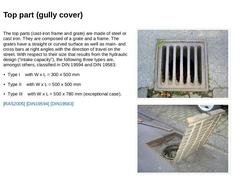

The top parts (cast-iron frame and grate) are made of steel or cast iron. They are composed of a grate and a frame. The grates have a straight or curved surface as well as main- and cross bars at right angles with the direction of travel on the street. With respect to their size that results from the hydraulic design (“intake capacity”), the following three types are, amongst others, classified in DIN 19594 and DIN 19583: |

|

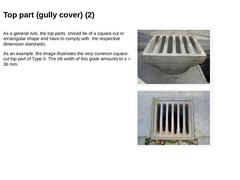

As a general rule, the top parts should be of a square-cut or rectangular shape and have to comply with the respective dimension standards. As an example, the image illustrates the very common square-cut top part of Type II. The slit width of this grate amounts to s = 36 mm. (Image: Cast-iron frame and grate (Type II) for road gullies according to DIN 19583-1) (Image: Top part (type II) for catch basins according to DIN 19583-1) |

|

The top part (cast-iron frame and grate) take over the function of a screen for the retention of coarse material, such as leaves, branches, grass, etc. on the surface of the road. (Image: Catch basin grate) (Image: Top part (Type II) for catch basins) |

|

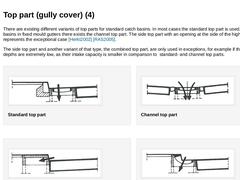

There are existing different variants of top parts for standard catch basins. In most cases the standard top part is used. For catch basins in fixed mould gutters there exists the channel top part. The side top part with an opening at the side of the high kerb represents the exceptional case [Herkt2002] [RAS2005]. The side top part and another variant of that type, the combined top part, are only used in exceptions, for example if the sewer depths … |

|

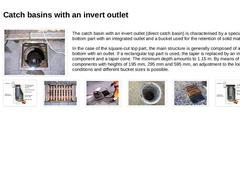

(Image: View into the bottom part of a catch basin with invert outlet) The catch basin with an invert outlet (direct catch basin) is characterised by a specially shaped bottom part with an integrated outlet and a bucket used for the retention of solid matter. In the case of the square-cut top part, the main structure is generally composed of a taper and a bottom with an outlet. If a rectangular top part is used, the taper is replaced by an intermediate … |

|

The buckets are standardised in Germany. They are equipped with slit rows and holes and have the function of a sieve that is installed in order to retain coarse materials and in particular floating substances. They are hung from the frame of the top part. The dimensions of the slits are 8 mm x 60 mm, whereas those that are arranged on the upper edge of the bucket have dimensions of 40 mm x 100 mm or a diameter of 40 mm. [DIN4052:2006] |

|

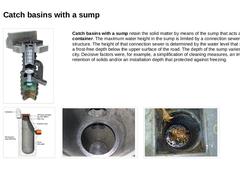

(Image: Separation catch basin) Catch basins with a sump retain the solid matter by means of the sump that acts as a settling container. The maximum water height in the sump is limited by a connection sewer in the main structure. The height of that connection sewer is determined by the water level that should be in a frost-free depth below the upper surface of the road. The depth of the sump varies from city to city. Decisive factors were, for example, … |

|

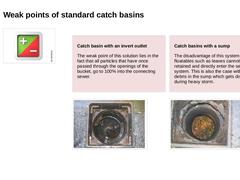

Catch basin with an invert outlet The weak point of this solution lies in the fact that all particles that have once passed through the openings of the bucket, go to 100% into the connecting sewer.

(Image: Catch basin with an invert outlet) Catch basins with a sump The disadvantage of this system is that floatables such as leaves cannot be retained and directly enter the sewer system. This is also the case with the debris in the … |

|

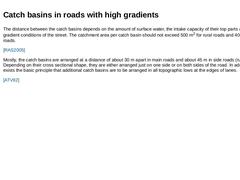

The distance between the catch basins depends on the amount of surface water, the intake capacity of their top parts and the gradient conditions of the street. The catchment area per catch basin should not exceed 500 m2 for rural roads and 400 m2 for urban roads. [RAS2005] Mostly, the catch basins are arranged at a distance of about 30 m apart in main roads and about 45 m in side roads (rural roads). Depending on their cross sectional shape, they are … |

|

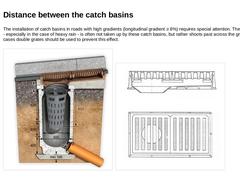

The installation of catch basins in roads with high gradients (longitudinal gradient ≥ 8%) requires special attention. The surface water - especially in the case of heavy rain - is often not taken up by these catch basins, but rather shoots past across the grate. In these cases double grates should be used to prevent this effect. (Image: Double grate according to ATV) (Image: Double grate - sectional and top view) |

|

|

|

For about 30 years now, people have been continually engaged in further developments of catch basins with the objective of improving both by means of technical and constructional changes. In recent years, the objectives were amended by the requirement to also use catch basins as local systems for the treatment of contaminated … |

|

The solid retention in the bucket is essentially influenced by the entry of organic matter in the form of leaves, limbs and other bulky objects. When a catch basin does not hold organic matter in its bucket, there is practically no solid retention, because the mineral solids with particle sizes of < 16 mm pass through the slit openings with the slightest volumetric flow. Consequently, catch basins with an outlet at the invert level are generally inappropriate … |

|

Owing to this knowledge, many authors recommend, amongst others, the replacement of conventional catch basins by new structures with improved cleaning functions or solid retention. This improved separation of solids from the flow reduces operational requirements in by increasing cleaning intervals. [SteinR08] [Artie1988] [Sander1994] [Bromb1993] [Grott1991] [Giesl1997] [Kraut2000] [Stotz1998] [Somme2004a] [Somme2004] [Fraen2005] [Hilli2005] Such requirements … |

|

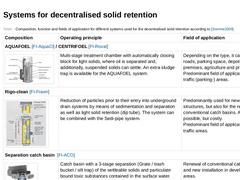

(Table: Composition, function and fields of application for different systems used for the decentralised solid retention) To see the images from the table in full view, please click on the images. |

|

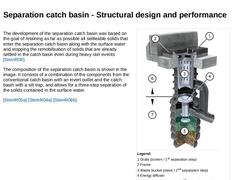

(Image: Separation catch basin) Out of all the catch basins introduced in the previous table, the separation catch basin is the only one that has been developed especially for the decentralised retention of settleable solids. Therefore, it is described in detail in the following section. Furthermore, the separation catch basin is also appropriate for the limitation of severe water pollution levels, because it interrupts the relevant input of particulate … |

|

The development of the separation catch basin was based on the goal of retaining as far as possible all settleable solids that enter the separation catch basin along with the surface water and stopping the remobilisation of solids that are already settled in the catch basin even during heavy rain events [SteinR08]. The composition of the separation catch basin is shown in the image. It consists of a combination of the components from the conventional … |

|

|

|

Without doubt, the biggest problem of our sewer systems are the laterals or drain pipes of drain systems as well as the street run-offs and their connection to public sewers. Apart from individual exceptions that will be dealt with in detail later on, there was the request that “laterals should, as a rule discharge into the sewers outside of the manholes” (ATV-A 214) up until the introduction of DIN EN 1610 in 1997. [ATVA241a] [EN1610:2015] |

|

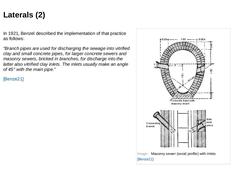

In 1921, Benzel described the implementation of that practice as follows: “Branch pipes are used for discharging the sewage into vitrified clay and small concrete pipes, for larger concrete sewers and masonry sewers, bricked in branches, for discharge into the latter also vitrified clay inlets. The inlets usually make an angle of 45° with the main pipe.” [Benze21] (Image: Masonry sewer (ovoid profile) with inlets [Benze21]) |

|

Usually, and especially in the installation of subsequent connections, this was carried out by means of chiselling open the sewer and cementing up the space between the inserted lateral and the hole broken into the sewer walling. With this method, it is not possible to make a permanently leaktight and flexible joint. In addition, there is the danger that the sewer can itself be uncontrollably damaged in the form of cracks, fragmentation and pipe breakage. |