|

|

|

| (Bild: Infrastrukturen im städtischen Untergrund [FI-Steina])

|

|

|

| (Bild: Innerstädtische Leitungsverlegung)

|

Die im Bereich öffentlicher Verkehrsflächen üblichen und grundsätzlich knapp bemessenen Abstände sind darauf zugeschnitten, mechanische, thermische oder elektrische Beeinflussungen auszuschließen, aber nicht darauf, bautechnische Behinderungen beim Errichten zusätzlicher Systeme oder beim Erweitern bestehender Systeme zu vermeiden. Abstände, die bautechnische Behinderungen ausschließen, sind in Verkehrsflächen … |

|

|

| (Bild: Dokumentation)

|

Eine der Realität entsprechende Leitungsdokumentation ist meist nicht vorhanden, selbst die Besitzer der Leitungsnetze haben oftmals keine genaue Kenntnis über die Lage ihrer Leitungen. Dies bedeutet, dass im unterirdischen Bauraum nicht generell von normgemäßer Anordnung der Leitungen ausgegangen werden kann. | |

(Bild: Erdverlegte Leitungen in New York um 1916 [Boegl69])

|

(Bild: Nicht fachgerecht verlegte Kabel und Leitungen [… |

|

|

|

|

(Bild: Leitungskanal [FI-Steina]) |

Leitungskanäle sind unterirdische Anlagen zur geordnetenVerlegung von Ver- und/oder Entsorgungsleitungen unter Einbeziehung der baulichen Hülle zur Leitungsbefestigung oder -unterstützung mit Hilfe von Dübeln, Spannschellen, Mehrfachschellen oder Leitungsunterstützungen. Um die Möglichkeit eines späteren Zugriffs auf die Leitungen zu erhalten, werden die verbleibenden Zwischenräume nicht verfüllt. |

|

|

|

(Bild: Begehbarer Leitungsgang [FI-Steina]) |

Beim begehbaren Leitungsgang handelt es sich um eine geschlossene, langgestreckte, begehbare bauliche Anlage zur zugänglichen Verlegung von Ver- und/oder Entsorgungsleitungen, bestehend aus Leitungsgangstrecke sowie Zugangs-, Montage-, Belüftungs-, Abzweig- und Vereinigungsbauwerken [Stein02] [Stein94a] [Stein97d] [Stein98e]. |

|

|

|

|

| (Bild: Gebäudeentwässerung über Grundleitung und Anschlusskanal mit Einsteigschacht auf dem Grundstück)

|

|

|

|

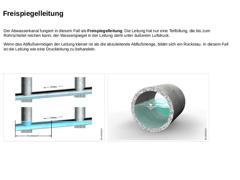

Der Abwasserkanal fungiert in diesem Fall als Freispiegelleitung: Die Leitung hat nur eine Teilfüllung, die bis zum Rohrscheitel reichen kann; der Wasserspiegel in der Leitung steht unter äußerem Luftdruck.

Wenn das Abflußvermögen der Leitung kleiner ist als die abzuleitende Abflußmenge, bildet sich ein Rückstau. In diesem Fall ist die Leitung wie eine Druckleitung zu behandeln. |

(Bild: Prinzip Gefälle und Darstellung des Druckbereiches bei Rückstau) |

|

|

|

|

Haltung nach DIN 4045 [DIN4045:1985]: Strecke eines Abwasserkanals zwischen zwei Schächten und/oder Sonderbauwerken. (Bild: Haltung - Strecke eines Abwasserkanals zwischen zwei Schächten und/oder Sonderbauwerken) |

|

|

| (Bild: Straßenquerschnitt mit Mischsystem) | | (Bild: Straßenquerschnitt mit Trennsystem) |

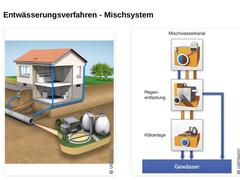

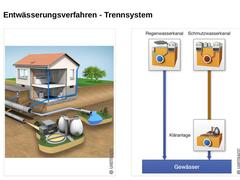

| | Bezüglich des Entwässerungverfahrens, d.h. der "Art der Ableitung von Abwasser" [DIN4045:2003] unterscheidet man z.B.: | | Mischsystem:

Entwässerungssystem zur gemeinsamen Ableitung von Schmutz- und Niederschlagswasser im gleichen [DINEN752:2008]. | | Trennsystem:

Entwässerungssystem, üblicherweise bestehend aus zwei Leitungs-/ Kanalsystemen für die getrennte Ableitung … |

|

|

|

| (Bild: Entwässerung als Mischsystem)

| (Bild: Schematische Darstellung des Abflusses beim Mischsystem - Darstellung einer Mischwasserentlastung für Spitzenabflüsse)

|

|

|

|

Modifiziertes Mischsystem:

Entwässerungssystem zur gemeinsamen Ableitung von Schmutz- und Niederschlagswasser im gleichen Leitungs-/Kanalsystem, wobei zwischen Niederschlagswasser mit unterschiedlichem Verschmutzungsgrad differenziert wird. Ziel ist, dass Niederschlagswasser so weit wie möglich aus dem Kanalnetz herauszuhalten. Nicht behandlungsbedürftiges Niederschlagswasser wird getrennt, in nahe liegende Gewässer abgeleitet, direkt, semizentral … |

|

|

| (Bild: Ableitung von Schmutz- und Niederschlagswasser im Trennsystem)

| (Bild: Schematische Darstellung des Abflusses beim Trennsystem)

|

|

|

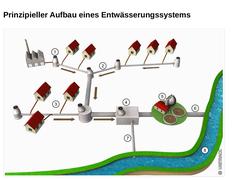

| (Bild: Prinzipieller Aufbau eines Abwasserentsorgungssystems)

|

|

|

|

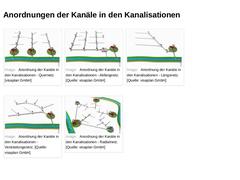

(Bild: Anordnung der Kanäle in den Kanalisationen - Quernetz)

|

(Bild: Anordnung der Kanäle in den Kanalisationen - Abfangnetz)

|

(Bild: Anordnung der Kanäle in den Kanalisationen - Längsnetz)

|

|

(Bild: Anordnung der Kanäle in den Kanalisationen - Verästelungsnetz)

|

(Bild: Anordnung der Kanäle in den Kanalisationen - Radialnetz)

|

|

|

|

|

|

|

DN/ID (internal diameter) ist das Kurzzeichen für Nennweite. Sie ist eine Kenngröße für Kreisquerschnitte in der Größenordnung Millimeter, jedoch ohne Angabe der Einheit mm. Sie entspricht annähernd dem lichten Durchmesser. (Bild: Nennweite DN) |

|

|

| (Bild: Abmessungen von Kreisquerschnitten für Kanäle nach DIN 4263 (07.47/07.77/04.91) [DIN4263] und DIN 19540 (12.52/09.64) [DIN19540])

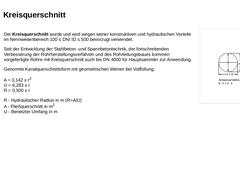

Der Kreisquerschnitt wurde und wird wegen seiner konstruktiven und hydraulischen Vorteile im Nennweitenbereich 100 ≤ DN/ ID ≤ 500 bevorzugt verwendet. Seit der Entwicklung der Stahlbeton- und Spannbetontechnik, der fortschreitenden Verbesserung der Rohrherstellungsverfahren und des Rohrleitungsbaues kommen vorgefertigte … |

|

|

| (Bild: Abmessungen von Eiquerschnitten für Kanäle nach DIN 4263 (07.47/07.77/04.91) [DIN4263] und DIN 19540 (12.52/09.64) [DIN19540])

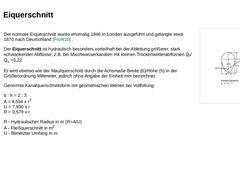

Der normale Eiquerschnitt wurde erstmalig 1846 in London ausgeführt und gelangte etwa 1870 nach Deutschland [Frühl10] . Der Eiquerschnitt ist hydraulisch besonders vorteilhaft bei der Ableitung größerer, stark schwankender Abflüsse, z.B. bei Mischwasserkanälen mit kleinen Trockenwetterabflüssen Qt/Qv =0,22. Er wird … |

|

|

| (Bild: Abmessungen von Maulquerschnitten für Kanäle nach DIN 4263 (07.47/07.77/04.91) [DIN4263] und DIN 19540 (12.52/09.64) [DIN19540])

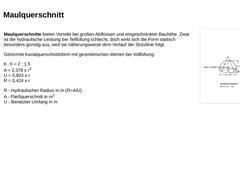

Maulquerschnitte bieten Vorteile bei großen Abflüssen und eingeschränkter Bauhöhe. Zwar ist die hydraulische Leistung bei Teilfüllung schlecht, doch wirkt sich die Form statisch besonders günstig aus, weil sie näherungsweise dem Verlauf der Stützlinie folgt. Genormte Kanalquerschnittsform mit geometrischen Werten … |

|

|

|

In Sonderfällen z.B. beim Bau von Stauraumkanälen, Regenrückhaltebecken oder bei vorgegebenen Trassierungszwangspunkten fanden und finden auch Rechteckquerschnitte Anwendung. Als kleinstes lichtes Achsmaß empfiehlt DIN 4263 [DIN4263:1991] ca. 800 mm. Die Sohle erhält eine Querneigung. |

|

(Bild: Stahlbetonrohre in Anlehnung an [DIN4035] - Kastenprofil Typ 2 [Bild: S&P GmbH]) |

|

(Bild: Stahlbetonrohre in Anlehnung an [DIN4035] - Kastenprofil Typ 1 [… |

|

|

|

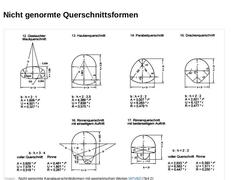

| (Bild: Nicht genormte Kanalquerschnittsformen mit geometrischen Werten [ATV82] (Teil 1))

|

|

|

| (Bild: Nicht genormte Kanalquerschnittsformen mit geometrischen Werten [ATV82] (Teil 2))

|

|

|

|

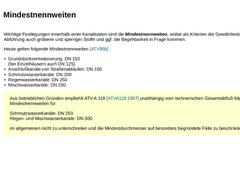

Wichtige Festlegungen innerhalb einer Kanalisation sind die Mindestnennweiten, wobei als Kriterien die Gewährleistung der Abführung auch gröberer und sperriger Stoffe und ggf. die Begehbarkeit in Frage kommen. Heute gelten folgende Mindestnennweiten [ATV95b] : - Grundstücksentwässerung: DN 150

(bei Einzelhäusern auch DN 125)

- Anschlußkanäle von Straßenabläufen: DN 150

- Schmutzwasserkanäle: DN 200

- Regenwasserkanäle: DN 250

- Mischwasserkanäle: DN 250.

| |

Aus … |

|