|

Surge flushing is the oldest sewer system cleaning method and is once again in demand as a result of new developments in sensor technology and telecontrol engineering. Preferred areas of use include stormwater retention tanks and storage channels. |

|

Compared to conventional high pressure cleaning, surge flushing is economically preferable, if the following conditions are present [Dohma2002a]: -

complicated access for both cleaning vehicles and staff,

-

extensive safeguards with respect to traffic control prior to high pressure cleaning,

-

need for short cleaning intervals (e.g. monthly),

-

very large deposit quantities,

-

predominantly loose, unconsolidated deposits,

-

long cleaning distances,

-

frail …

|

|

A practical approach to operational concept and appropriate planning are required to apply the method of surge flushing efficiently and successfully in the long term. As to planning, [Dohma2002a] recommends to complete these five steps in the following order: (Image: Flushing methods - Operational concept) |

|

In step 1 the applicability of surge flushing is tested in relation to the local circumstances as well as the structural, hydraulic and material limiting conditions in the sewer. |

|

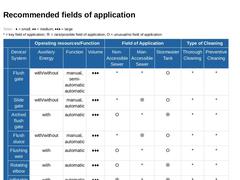

In step 2, the appropriate surge flushing devices are determined considering their specific fields of application, and the requirements that are defined by the limiting conditions (step 1).

The following table includes recommendations regarding the selection of surge flushing methods depending on the operating resources/function, fields of application and type of cleaning. They are categorized into man-accessible and non-accessible sewers (< DN 800). |

|

(Table: Recommended fields of application and characteristics for surge flushing devices in accordance with [Dettm2005a]) |

|

In step 3, the location for the chosen surge flushing device is specified. The location should preferably be immediately in front of the sewer section that is exposed to deposits, and allows for an easy access. Furthermore, depending on the function of the surge flushing device, it is important to ensure the availability of electrical and data services.

In step 4, the investment and operational costs for all surge flushing devices worth considering … |

|

In step 5, the flushing water volumes for individual surge waves are determined. Based on these calculations, a flushing plan is developed, which specifies the: -

type,

-

number, and

-

arrangement

of the surge waves depending on the local circumstances and the cleaning task. |

|

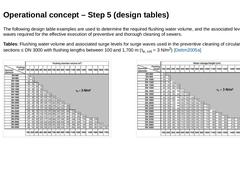

The following design table examples are used to determine the required flushing water volume, and the associated levels of surge waves required for the effective execution of preventive and thorough cleaning of sewers. Tables: Flushing water volume and associated surge levels for surge waves used in the preventive cleaning of circular cross sections ≤ DN 3000 with flushing lengths between 100 and 1,700 m (τe, crit = 3 N/m2) [Dettm2005a] |

|

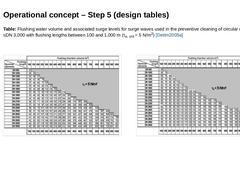

Table: Flushing water volume and associated surge levels for surge waves used in the preventive cleaning of circular cross sections ≤DN 3,000 with flushing lengths between 100 and 1,000 m (τe, crit = 5 N/m2) [Dettm2005a] (Image: Flushing water volume and associated surge levels for surge waves used in the preventive cleaning of circular cross sections ≤ DN 3,000 with flushing lengths between 100 and 1,000 m (τe, crit = 5 N/m2)) |

|

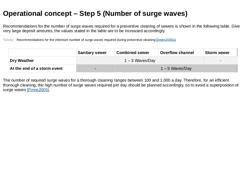

Recommendations for the number of surge waves required for a preventive cleaning of sewers is shown in the following table. Given very large deposit amounts, the values stated in the table are to be increased accordingly. (Table: Recommendations for the minimum number of surge waves required during preventive cleaning) The number of required surge waves for a thorough cleaning ranges between 100 and 1,000 a day. Therefore, for an efficient thorough … |

|

|

|

Based on the results of large-scale tests performed on storm water sewers (DN 2,500 to DN 3,400) the following conclusions, according to [Dettm2005], were drawn: -

In the case of thorough cleaning, stormwater sewers have to be designed for a critical erosion shear stress according to Shields of τe,crit = 11.9 N/m2. Here, a continuous flushing with a maximum number of surge waves per day is recommended. The surge waves should have a height of hsurge…

|

|

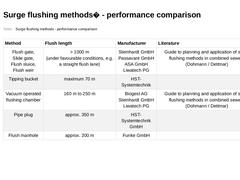

(Table: Surge flushing methods - performance comparison) |

|

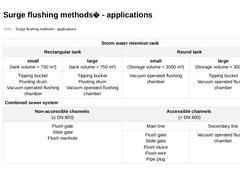

(Table: Surge flushing methods - applications) |

|

|

|

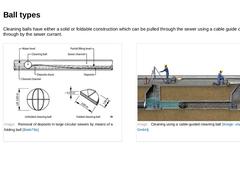

In the case of back-up flushing, devices are introduced into the sewer that reduce its flow cross section, back up the sewage and thus increase the flow velocity. As a result of the difference in the water level in front of and behind the devices, they are driven forward as the flushing water flows around them. In the process, the unconsolidated deposits are removed and transported [Führb1980]. |

|

Back-up flushing cannot be applied in cases of meshed networks or low line gradients. Instead of the required difference in the water level that produces increased flow velocities, the water levels in front of and behind the back up device oscillate until they reach equilibrium conditions. In that case the flow velocity between the device and the sewer wall does not suffice for the removal and transport of deposits. Furthermore, there is the risk … |

|

In the case of back-up flushing, the following mobile devices are used [NASSCO1989] [Frühl1910] [Gürsc1921] [Tchob1989] [Führb1980]: -

Cleaning balls

-

Flushing shields

(Image: Back-up flushing Cleaning balls – Process description) (Image: Back-up flushing equipment - Flushing shield) |

|

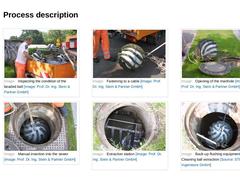

This method comprises the transport of spherical devices with structured surfaces through drainage channels for the sole purpose of deposit removal [DIN EN 14654-1]. (Image: Cleaning balls in different sizes) |

|

Cleaning balls have either a solid or foldable construction which can be pulled through the sewer using a cable guide or pushed through by the sewer currant. (Image: Removal of deposits in large circular sewers by means of a folding ball [Biele1979]) (Image: Cleaning using a cable-guided cleaning ball) |

|

The cleaning process involving freely moving solid balls developed at the start of the 1980s, and included using floating beaded balls which enabled for the continuous automatic cleaning of non-solidified deposits in channels [Dinke1987]. (Image: Beaded balls - Retreval by hand) |

|

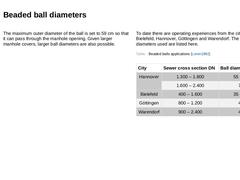

The maximum outer diameter of the ball is set to 59 cm so that it can pass through the manhole opening. Given larger manhole covers, larger ball diameters are also possible. To date there are operating experiences from the cities of Bielefeld, Hannover, Göttingen and Warendorf. The ball diameters used are listed here. (Table: Beaded balls applications) |

|

(Video: Depiction of principle of cleaning with beaded cleaning balls) Video: Cleaning process with the automatic insertion and extraction of beaded balls [Dinke87] [Image: visaplan GmbH]. This interactive object is only visible online. |

|

| (Image: Back-up flushing Cleaning balls – Process description) | (Image: Back-up flushing Cleaning balls – Process description) | (Image: Back-up flushing Cleaning balls – Process description) | | (Image: Back-up flushing Cleaning balls – Process description) | (Image: Back-up flushing Cleaning balls – Process description) | (Image: Back-up flushing Cleaning balls – Process description) |

|