|

When using the rotary chain cutter, it is recommended to proceed as follows [FI-KEG]: -

Loose deposits are to be flushed out in advance.

-

Working in one location involves the risk of scouring the pipe.

-

Carefully select the appropriate chain lengths. The chains should brush past, but should not touch, and on no account hit the pipe wall.

-

After each use, the rotary chain cutter is to be visually inspected to find possible damage. Defects are to be …

|

|

When using the rotary chain cutter, it is recommended to proceed as follows [FI-KEG] (cont.): -

A swivel joint should be arranged between the hose and the rotary chain cutter to prevent the HP hose from twisting.

-

The use of clean water is a basic precondition for a trouble-free operation and a long service life of a hydraulically driven rotary chain cutter.

-

Storage: It is recommended to store the device after its use with its top pointing upwards (…

|

|

(Video: Root removal using a rotary chain cutter) Video: Rotary chain cutter in use [FI-KEG] |

|

|

|

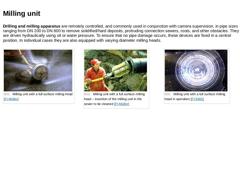

Drilling and milling apparatus are remotely controlled, and commonly used in conjunction with camera supervision, in pipe sizes ranging from DN 200 to DN 600 to remove solidified/hard deposits, protruding connection sewers, roots, and other obstacles. They are driven hydraulically using oil or water pressure. To ensure that no pipe damage occurs, these devices are fixed in a central position. In individual cases they are also equipped with varying … |

|

(Video: Principle of root removal with a drilling device) Video: Root removal using a milling unit [FI-Kasap][Image: visaplan GmbH]. This interactive object is only visible online. |

|

The automatic impact boring machine falls within the category of “drilling and milling apparatus with and without impact“. It was developed to remove solidified deposits, congestions and root intrusions for nominal sewer sizes ranging from about DN 100 to DN 1,000. (Image: Automatic impact boring machine for varying pipe sizes) (Image: Root removal using the automatic impact boring machine) |

|

(Image: Automatic impact drilling and milling units for various sewer sizes) |

|

The drilling tool is composed of a steel drilling head equipped with exchangeable carbide metal cutting knives dimensioned to the sewer diameter. In the case of root intrusions or other soft material deposits, the drilling head is equipped with serrated knives made of steel. (Image: Milling head calibration for a DN 200/300 pipe) (Image: Milling unit for a DN 200/300 pipe) Images: Automatic Impact Boring unit with guide sled in the root cutter version [… |

|

The following recommendations apply to the impact/milling tools: -

The use of milling and impact milling tools requires a good structural condition of the pipe.

-

Milling is not permitted in sewers made of vitrified clay.

-

The use in PVC pipes is not recommended.

|

|

|

|

Cutting apparatus are used to eliminate protruding obstacles in sewer lines such as lateral connections, artificial obstacles as well as roots in pipe sizes ranging from DN 100 to DN 600, and often under video supervision [NASSCO1989] [WPCF1985]. The operating principles are different for devices that use mechanical cutters versus those that use pressurised water jets.

|

|

|

The pipe saw borer falls within the category of mechanically working devices that are generally no longer in use today. It is based on the use of a saw blade as a cutting tool that moves forwards and backwards while rotating at the same time. Cooling and cleaning are achieved through the automatic wetting of the saw blade with water. |

(Image: Pipe saw borer - front view) |

|

(Image: Pipe saw borer) |

(Image: Pipe saw borer in operation) |

|

|

The root cutter is equipped with a cutting blade that is hydraulically operated for removing severe root intrusions. The cutter is also equipped with a HP flushing device and can be used in nominal pipe sizes ranging between DN 100 and DN 400.

(Image: Hydrodynamically driven root cutter with rotating spring blade) |

|

|

|

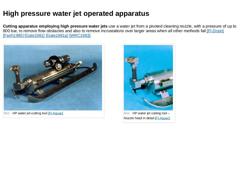

Cutting apparatus employing high pressure water jets use a water jet from a pivoted cleaning nozzle, with a pressure of up to 800 bar, to remove flow obstacles and also to remove incrustations over larger areas when all other methods fail [FI-Drain] [Fairh1985] [Gale1981] [Gale1981a] [WRC1983]. (Image: HP water jet-cutting tool) (Image: HP water jet cutting tool – Nozzle head in detail) |

|

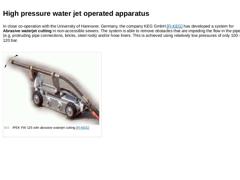

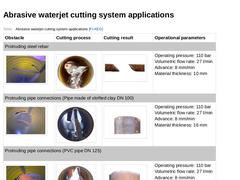

In close co-operation with the University of Hannover, Germany, the company KEG GmbH [FI-KEG] has developed a system for Abrasive waterjet cutting in non-accessible sewers. The system is able to remove obstacles that are impeding the flow in the pipe (e.g. protruding pipe connections, bricks, steel rods) and/or hose liners. This is achieved using relatively low pressures of only 100 – 120 bar. (Image: IPEK FW 125 with abrasive waterjet cutting) |

|

(Table: Abrasive waterjet cutting system applications) |

|

|

|

Sandblasters can be used to achieve a very high degree of cleaning, especially for achieving a bare metal surface in steel and cast iron pipes. The equipment is pulled into the pipe to be cleaned and then slowly pulled back during sandblasting along with the air hose. These devices are available for the pipe sizes ranging from DN 60 to DN 1,600. (Image: Sandblaster with rotating sandblasting head, and centring trolley for pipes between DN 350 and … |

|

|

(Image: Sandblasting of the brickwork)Sandblasting of brickwork |

(Image: Sandblasted brickwork)Sandblasted brickwork |

(Image: Strahlmittel Sakresiv 0,2 - 0,8 mm)Abrasive “Sakresiv” 0.2-0.8 mm |

|

Images: Sandblasting of a brick sewer [Image: Prof. Dr. Ing. Stein & Partner GmbH] |

Sandblasting is also often used in combination with a hand held HP spray gun in man accessible sewers as a preparatory measure prior to the application of additional coatings. … |

|

One of the disadvantages of sandblasting is the accumulation and removal of the abrasive waste material from the channel. Therefore, an alternative method that produces no abrasive residues was developed. The so called “Jetty Robot” system applies dry ice as an abrasive, and is predominantly used for the cleaning of air ventilation ducts ranging from DN 400 to DN 1,300. (Image: Jetty Robot – Track-driven chassis, illumination unit, camera and nozzle) |

|

|

|

Compared to all of the previously mentioned special apparatus, the sewer robot has proven to be the most effective in practice. (Image: Milling robot HF 100 [FI-Kanala] - For use in nominal pipe sizes from DN 200 to DN 600) (Image: Milling of a protruding lateral connection) (Image: Root removal and milling of the intrusion area) |

|

|