|

The nozzle is described in Brockhaus' "ABC's of Science and Technology" as the mouthpiece of the pipe which is used to narrow the flow channel, thus transforming pressure into velocity (pressure nozzle) or velocity into pressure (suction nozzle). Consecutively, the following definition is used: The flushing nozzle head is understood to include either fixed jetting inserts, or threaded bores into which the corresponding jetting inserts can be screwed. |

|

Nozzles used for cleaning purposes (subsequently also called cleaning nozzles) serve to generate the required jets of liquid (pressurised water jets, in literature often called high-pressure water jets) to: -

Propel the flushing hose from the starting manhole to the target manhole and to

-

Loosen and transport deposits.

-

Transporting the deposits

(Image: HP flushing nozzles) |

|

|

|

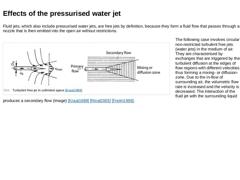

Fluid jets, which also include pressurised water jets, are free jets by definition, because they form a fluid flow that passes through a nozzle that is then emitted into the open air without restrictions. (Image: Turbulent free jet in unlimited space) The following case involves circular non-restricted turbulent free jets (water jets) in the medium of air. They are characterised by exchanges that are triggered by the turbulent diffusion at the edges … |

|

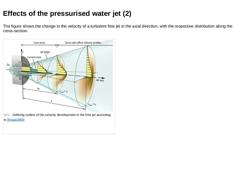

The figure shows the change in the velocity of a turbulent free jet in the axial direction, with the respective distribution along the cross-section. (Image: Defining outline of the velocity development in the free jet according to [Kraat1989]) |

|

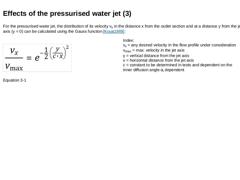

For the pressurised water jet, the distribution of its velocity νx in the distance x from the outlet section and at a distance y from the jet axis (y = 0) can be calculated using the Gauss function [Kraat1989]: (Formula: Geschwindigkeitsverteilung des Druckwasserstrahls (Gauß-Funktion)) Equation 3-1 Index: νx = any desired velocity in the flow profile under consideration

νmax = max. velocity in the jet axis

y = vertical distance from the jet axis

x = … |

|

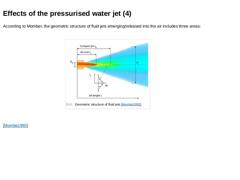

According to Momber, the geometric structure of fluid jets emerging/released into the air includes three areas: (Image: Geometric structure of fluid jets) [Mombe1993] |

|

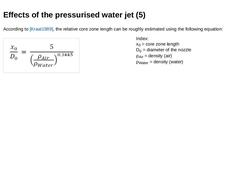

According to [Kraat1989], the relative core zone length can be roughly estimated using the following equation: (Formula: Equation to roughly estimate the relative core zone length) Index: x0 = core zone length

D0 = diameter of the nozzle

ρAir = density (air)

ρWater = density (water) |

|

|

|

The cleaning quality is influenced by the quantity of water used in the procedure (volumetric flow rate), the speed at which the nozzle is pulled back through the sewer, the pressure and effectiveness of the pressurised water jets, and the following nozzle features: -

Nozzle type

-

Size, geometry and weight

-

Number and diameter of the nozzle inserts

-

Material of the nozzle

-

Material of the nozzle inserts

-

Pressure losses within the nozzle (jet deflection)

|

|

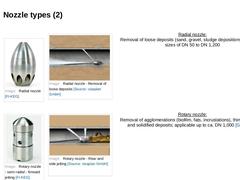

Various cleaning nozzles are available depending on the type and amount of deposits or obstructions, channels cross-sectional shape, and cleaning goal. They are divided into: a) Radial nozzles (pressurised water jets emerge radially backwards, distributed along the length/extent of the nozzle) b) Rotary nozzles (like radial nozzle, in addition, the cleaning nozzle rotates) c) Penetrator nozzles (pressurised water jets emerge backwards and forwards) d) |

|

|

(Image: Radial nozzle) |

(Image: Radial nozzle - Removal of loose deposits) |

Radial nozzle:

Removal of loose deposits (sand, gravel, sludge depositions) in nominal sizes of DN 50 to DN 1,200 |

|

(Image: Rotary nozzle - semi radial - forward jetting) |

(Image: Rotary nozzle - Rear and side jetting) |

Rotary nozzle:

Removal of agglomerations (biofilm, fats, incrustations), thin roots, loose and solidified deposits; applicable up to ca. DN 1,000 [Geib2002] |

|

|

This type of nozzle is used mainly for cleaning of the entire circumference of the inner pipe wall. The nozzle inserts are radially distributed over the entire circular cross-section allowing for a uniform distribution of the water jets.This application is best suited for pipe sizes ranging from DN 50 to DN 1200. The radial nozzle is not as effective in large diameter channels because not enough cleaning energy is applied to the pipe invert to achieve … |

|

Video: Radial nozzle in use [FI-KEG]. This object is only visible in the online version of the module. Video: Radial nozzle in use [FI-KEG]. This video is only visible in the online version of the module. Video: Radial nozzle in use [FI-KEG]. This video is only visible in the online version of the module. |

(Video: Radial nozzle in use) |

(Video: Radial nozzle in use) |

(Video: Radial nozzle in use) |

|

|

This nozzle type is used in particular prior to an inspection or rehabilitation as it provides a full-surface cleaning of the pipe wall. This type of nozzle tends to form aerosols. The cleaning performance is achieved as with other types of nozzles through a combination of rearward propulsion and cleaning jets. The cleaning of the pipe invert is performed by the radially arranged jets in the rotating middle section of the nozzle. |

|

Having the jetting nozzles at a right angle results in the water jets perpendicularly impacting the pipe wall. This type of nozzle is optimal for the cleaning of pipes with a low to moderate degree of pollution and moderate deposit levels. The rear facing jets are used to advance the nozzle through the pipe and to carry away the loosened debris. (Image: Rotating nozzle - with 90° radial jets) |

|

(Image: Rotating nozzle - Half radial rear-facing jets) (Image: Rotating nozzle - Half radial rear-facing jets) (Image: High-pressure cleaning using a rotating nozzle) The half radial nozzle has jetting angles bellow 45° and is used in pipes with a mild to moderate degree of pollution to remove light to medium deposit levels. In addition to the radial jet version, the nozzle manufacturer also offers additional rear facing thrust jets which provide greater … |

|

(Image: Rotary nozzle - semi radial - forward jetting) (Image: Rotating nozzle - Half radial forward-facing jets) This type of nozzle is characterized by the forward-facing cleaning jets used for the removal of blockages in the drive direction. Rear-facing thrust jets are set at a 45 ° angle, and are used to advance the nozzle and transport the waste material. |

|

|

|

(Image: Chisel Point Nozzle for removal of blockages) (Image: Chisel Point Nozzle) The chisel point nozzle uses its multiple rear and forward facing jets and sharp edges to penetrate most blockages. Its geometry and penetration capabilities are most often used to remove blockages caused by pipe failures and cave ins. |

|

|

|

The comparatively high weight and unique design of these nozzles makes them particularly suitable for the cleaning of channels with a diameter greater than DN 250. Radial jetting nozzles have a tendency to float in submerged channels, therefore losing some of their cleaning effectiveness. The flat nozzle overcomes this downside through its unique design which keeps it very stable and predictable. Propulsion is achieved through rear facing thrust … |

|

(Image: Invert nozzle detail) (Image: Invert nozzle in operation) Flat nozzles are equipped with interchangeable jet inserts. The nozzles are designed for high flow rates, which in conjunction with a low jet angle produces a very high discharge force.

A rotary joint is used between the nozzle and the high-pressure hose in order to prevent the occasional rotation of the hose from affecting the nozzles optimal position in the pipe invert. |

|

(Image: Flat wedge nozzle with a pivoting joint) Attaching a vertically pivoting joint along with increasing its overall weight minimise the flat nozzles tendency to hydroplane. Its firm positioning in the channel and wedge shape design prevent the nozzle from getting jammed and ensure a sufficient cleaning of the pipe invert. Additional front facing jetting nozzles can be used to increase the cleaning performance and improve the forward progress … |

|

|