|

|

|

The Insituform-KAS process corresponds in principle with the Insituform process mentioned above. An entry manhole or a correspondingly large space in the building is always required for the inversion of the UP or EP resin soaked prefabricated liner hose of needle felt. To save space, an enclosed cylindrical pressure vessel or a pressure hose is used in the place of the inversion scaffold. The impregnated liner is kept in this vessel or hose and from … |

|

(Image: Remote controlled lateral rehabilitation with the Insituform process (FAS) [FI-Insit] [Dilg98]) The Insituform FAS process is based on a further development of the top hat profile technique and can, among others, also be carried out directly from the sewer. In this case, an installation module is coupled to a pressure hose and in this a UP resin soaked liner hose pulled into a supporting hose is situated. A plastics form piece (flange) is fitted … |

|

In the KM-Houseliner process, the liner hose consists of an approx. 3 mm thick glass fibre knitted hose that is soaked by a mobile roller apparatus in-situ with a cold hardening epoxy resin specially developed for adhesion on a moist pipe (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3) (Bild 5.3.2.4.1.3.3). |

(Image: KM-Houseliner working steps [FI-KMG] - Pulling the glass … |

|

|

The Brawoliner process is based on a carrier hose of 100 % polyester impregnated with cold-hardening epoxy resin and an integrated foil hose that is originally on the outside. According to the manufacturer's information , it was developed especially for the fold-free lining of laterals of DN 100 to 200 with small bend radii and bends up to 90°. The installation of the liner hose is carried out in the inversion process with compressed air (Bild 5.3.2.4.1.3.4) |

|

|

(Image: Kondur-Home-Liner process [FI-Preus] - Lining the lateral by means of inverting the liner through a manhole)

|

|

(Image: Kondur-Home-Liner process [FI-Preus] - Inversion drum)

|

The Home-Liner process, in use since 1995, comes in 2 variants and consists of a PU/PVC lined polyester needle felt hose, approx. 3 to 6 mm thick that can be soaked with cold and warm-hardening epoxy resins, and is hardened without shrinking [FI-MCBau]. In the first … |

|

In the INFlex system [FI-UVRel], the 2-component EP resin soaked liner hose is wound in a pressure chamber and is inverted through an entry manhole with the aid of compressed air into the lateral to be rehabilitated. There are two variants as regards the hardening of the resin: either cold hardening or using UV lamps. Depending on the variation used, the nominal size range is DN 50 to DN 250 and can be used to length up to 40 m. The wall thickness … |

|

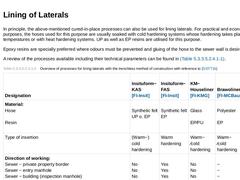

In principle, the above-mentioned cured-in-place processes can also be used for lining laterals. For practical and economical purposes, the hoses used for this purpose are usually soaked with cold hardening systems whose hardening takes place at ambient temperatures or with heat hardening systems. UP as well as EP resins are utilised for this purpose. Epoxy resins are specially preferred where odours must be prevented and gluing of the hose to the … |

|

ATV-M 143E Part 3 [ATVM143-3] defines the cured-in-place process as follows: "A hose of carrier material that can be coated with foil is soaked with reaction resin and inverted into the sewer through a manhole by means or water or compressed air or is pulled into the sewer with the aid of a winch. The hardening is carried out at normal temperature, by the application of heat or UV light with the application of internal pressure. A sleeveless liner … |

|

As regards the preparatory work, the corresponding discussion of the Insituform process ( (Abschnitt 5.3.2) (Abschnitt 5.3.2.4.1) (Abschnitt 5.6.1) and [ATVM143-3]) is applicable. |

|

(Image: Sequence of the renovation of sewers by means of lining with site manufactured and hardened pipes - Grouted-in-place lining process) After TV inspection and measurement or calibration of the section of the sewer to be rehabilitated (Bild 5.3.2.4.2.2), the fabrication dimensions are determined for the HD-PE hoses to be installed (stud, preliner control hose). The HD-PE courses are then cut to the respective length and the required circumferential … |

|

The insertion of the individual hoses is carried out with the aid of an insertion installation whose erection is carried out as follows: - Erection of the deflection bend in the starting manhole

The deflection bend erected in the starting manhole (sometimes replaced with a deflection roller) serves to change the direction and to ensure safe insertion of the folded hose into the section of the sewer.

- Setting up the deformation unit (Bild 5.3.2.4.2.3) …

|

|

(Image: Working steps in the grouted-in-place lining process - Pulling-in the hoses) Depending on the selected system, as mentioned earlier, one or more of the hoses wound on drums are pulled via the entry manhole into the section of the sewer to be rehabilitated. After reaching the target manhole, the hoses are closed off at both ends with sealing balloons (Bild 5.3.2.4.2.4) (Bild 5.3.2.4.2.4) (Bild 5.3.2.4.2.4) (Bild 5.3.2.4.2.4) (Bild 5.3.2.4.2.4) |

|

Before starting the grouting of the annular space it must be sealed at the end faces at the start and target manholes (Bild 5.3.2.4.2.5). With the control and preliner hoses, this is achieved by extrusion welding the preliner with the stud hose (Bild 5.3.2.4.2.5). In the basic version, the stud hose is welded with fleece coated HD-PE sleeves at the pipe ends. |

(Image: Working steps in the grouted-in-place lining process [FI-Troli] - Welding on ventilation … |

|

|

Various manhole connecting systems based on HD-PE materials are available for the stud hose process depending on the requirements and the system used [FI-Troli]. One possibility of leaktight connecting the HD-PE liner for sections of the sewer of vitrified clay, GRP, concrete, etc. is the installation of a 2 to 5 mm and approx. 50 cm long fleece coated HD-PE sealing course. It is soaked in epoxy resin and pressed like a "short hose based on synthetic … |

|

According to [ATVM143-3] and similarly to [Gütes96], measures for own supervision must be taken wherever the quality of the rehabilitation can be disadvantageously influenced, for instance by: - Control and documentation of the cleaning, inspection, dimensioning and calibrating the section of the sewer to be rehabilitated.

- Entry control of the hoses to be inserted with information on parameters such as diameter, height of studs, welding parameters and …

|

|

The finishing works include (Abschnitt 5.3.2.2.1) the: - Connection to the manhole (Abschnitt 5.3.2.4.2.6.1) ;

- Adapting the liner to the manhole channels (Abschnitt 5.3.2.4.2.6.1) ;

- Restoring the branch connections (Abschnitt 5.3.2.4.2.6.2) ;

- Testing (Abschnitt 5.3.2.4.2.6.3).

|

|

|

|

In-situ concrete processes are used in sewers for creating self-supporting complete segmental linings consisting of a concrete or reinforced concrete shell which has no structural effective adhesion with the old sewer in order to prevent shrinking stresses. The adhesive connection is prevented by means of surface treatment of the inner wall of the old sewer or by interposing a separating layer, foil or sealing course. Depending on the type of mixing … |

|

Contrary to the lining with prefabricated or site manufactured pipes, in the lining with site manufactured and hardened pipes, a prefabricated, flexible hose is inserted into the section of the sewer to be rehabilitated and is pressed against the wall under pressure. There it hardens into a self-carrying liner through the reaction of a synthetic resin previously applied to the material of the hose or through the action of a hydraulic setting injection … |

|

Vitrified clay plates have been used since the turn of the 20th Century as complete or partial segmental lining of concrete and reinforced concrete pipes as corrosion protection as well as an economical alternative to the masonry sewer [König02b] [Stein13]. The first vitrified clay plates had a length of 330 mm, a width of 110 or 115 mm, a height of 20 mm and had longitudinal ridges on the back in order to achieve a secure adhesion to the cement mortar … |

|

|

(Image: Vitrified clay plate elements - Keraline system [FI-KIA] - Basic element: Vitrified clay plate with special rear side formation)

|

|

(Image: Vitrified clay plate elements - Keraline system [FI-KIA] - Anchoring the vitrified clay plate element in the mortar bed)

|

|

(Image: Vitrified clay plate elements - Keraline system [FI-KIA] - Invert lining of a masonry sewer with an ovoid cross section 1000/1310)

|

The technical manufacturing difficulties … |

|

The patented BLS system is based on glass fibre concrete channels (GRC) (Bild 5.3.2.5.1.3.1) (Bild 5.3.2.5.1.3.1) that are installed according to a special process (Bild 5.3.2.5.1.3.1) [Mülle82b]. The channels possess a groove and spring joint provided with a sealing strip that is so designed that slight changes in direction are equalised out. |

(Image: Concrete laminate channels (BL-channels) - Working steps during installation - Lowering BL-channels … |

|

|

Depending on nominal size and local conditions, prefabricated invert channels of reinforced concrete or glass fibre concrete (GRC) with a PVC-U lining can be used. The prefabricated parts, also known under the designation BKU-GRC, are used for ovoid cross sections in sizes 600/900 to 1200/1800, for semi-circular channels DN 150 to DN 700 and for third-circle segments from DN 250 to DN 600. The wall thickness is approx. 18 mm; the length varies for … |

|

|