|

| (Image: Equipment for lining with site manufactured pipes with anular space)

The RIB-LOC-Relining-System requires the following equipment: - 3 persons required on the site

- Winding machine with exchangeable winding forms

- Hydraulic pump for the drive

- Holder for the plastics profile pipe roller

- Light lifting equipment

- Equipment for leaktightness testing

- Equipment for annular space grouting

- Cutting, boring or milling tools for the connections (robot)

…

|

|

|

| (Image: Pros and cons)

|

Advantages of RIB-LOC-Relining-System: - short construction time

- few traffic restrictions

- re-establishment or increase of the static load bearing capacity of the pipeline to be rehabilitated

- possibility to reduce the drainage cross section of hydraulically oversized sewers

|

|

|

| (Image: Pros and cons) |

Disadvantages of RIB-LOC-Relining-System: - extensive re-restablishment of connection sewers in the non-accessible nominal size area when using the open-cut method

- reduction of the cross section of the pipeline to be rehabilitated

- damage areas must be sealed first due to strong water infiltration

- necessity of annular space grouting with buckling risk of the liner

- wastewater deposits in the annular space lead to cavities in the …

|

|

|

|

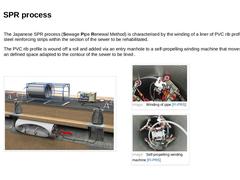

The Japanese SPR process (Sewage Pipe Renewal Method) is characterised by the winding of a liner of PVC rib profiles with steel reinforcing strips within the section of the sewer to be rehabilitated. The PVC rib profile is wound off a roll and added via an entry manhole to a self-propelling winding machine that moves along an defined space adapted to the contour of the sewer to be lined . | | (Image: Spiral lining process RotaLoc with reference to [FI-… |

|

|

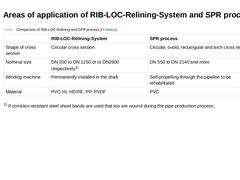

(Table: Comparsion of RIB-LOC-Relining and SPR process [FI-Steina]) |

|

|

|

|

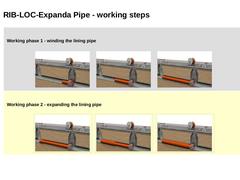

| RIB-LOC-Expanda Pipe |

(Video: Lining with site manufactured pipes without annular space - RIB-LOC-Expanda-Pipe process with reference to [FI-Preus] [Image: S&P GmbH])

|

|

(Image: RIB-LOC-Expanda Pipe - Working phase 2: Expanding the lining pipe by pulling the enclosed wire rope (working step 2))

|

| |

|

|

| Working phase 1 - winding the lining pipe |

(Image: RIB-LOC-Expanda Pipe - Working phase 1: Winding of the lining pipe from starting manhole to target manhole (working step 1))

|

(Image: RIB-LOC-Expanda Pipe - Working phase 1: Winding of the lining pipe from starting manhole to target manhole (working step 2))

|

(Image: RIB-LOC-Expanda Pipe - Working phase 1: Winding of the lining pipe from starting manhole to target manhole (working step 3))

|

| Working … |

|

|

|

|

The lecture deals with the method variants and the application areas of lining with spirally-wound pipes. |

|

The lecture "Lining with prefabricated pipes without annular space (Lining with close-fit pipes)" describes the two different method variants, deformation process and reduction process, as well as their areas and limits of application. |

|

|

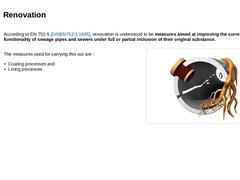

According to EN 752-5 [DINEN752-5:1995], renovation is understood to be measures aimed at improving the current functionality of sewage pipes and sewers under full or partial inclusion of their original substance. | |

The measures used for carrying this out are : - Coating processes and

- Lining processes .

| (Image: Damages)

|

|

|

| (Image: Distribution of the lining processes)

|

|

|

|

|

|

Full linings serve the purpose of replacing or enhancing the resistance properties to physical, chemical, biochemical and/or biological attacks, for hindering the renewed formation of incrustations, for replacing and/or increasing the static bearing capacity as well as the leaktightness. | |

(Image: Structural calculation)

|

|

(Image: Leaktightness)

|

|

|

|

|

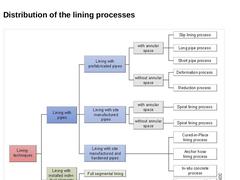

Lining processes are differentiated as follows - lining with pipes and

- Lining with installed individual elements (segmental lining process) in the form of

- Partial segmental lining of the invert region or the gas space and

- Full segmental lining

| Lining with pipes |

(Image: Lining with prefabricated pipes)

|

(Image: Lining with site manufactured pipes)

|

(Image: Lining with site manufactured and hardened pipes)

|

| Segmental lining (Image: Segmental lining)

|

|

|

The lining with pipes is understood to be, similar to (not found),the creation of self-supporting full lining of sewer sections based on -

Prefabricated pipes;

-

Site manufactured pipes; and

-

Site manufactured and hardened pipes.

(Image: Depiction of the lining with site manufactured pipes (spiral lining process) using the RIB-LOC-Relining-System as an example with reference to [FI-RIBLOb] - Sketch of principle [Image: S&P GmbH]) (Image: Insertion of … |

|

|

|

|

Lining with prefabricated pipes is characterised by the pulling, pushing or driving-in of pipes (also lining pipes) into the section of the sewer to be rehabilitated. One differentiates between: - Lining with continuous pipes

- Lining with discrete pipes

|

(Image: Conventional sliplining process with annular space with reference to [FI-Teerb] - Depiction of principle [Image: S&P GmbH])

|

(Image: Discrete pipe method - Pulling-in of discrete pipes into the … |

|

|

|

|

|

DIN EN 13566 / ATV-DVWK-M 143-11

Lining with close-fit pipes Lining with close-fit pipes:

Lining with a continuous pipe for which the cross-section is reduced to facilitate installation and reverted after installation to provide a close fit to the existing pipe [DINEN13566-1:2003]. | | (Image: Compact pipe process with reference to [FI-Wavin] - Pulling-in the C-shaped folded continuous pipe [Image: S&P GmbH])

|

|

|

DIN EN 13566 | Lining pipe Lining pipe:

Pipe to be inserted for renovation purposes [DINEN13566-1:2003]. | Liner Liner:

Lining pipe after installation [DINEN13566-1:2003]. | Lining system Lining system:

Lining pipe and all relevant fittings for insertion into an existing pipeline for the purposes of renovation [DINEN13566-1:2003]. |

|

|

|

European standards: DIN EN 752-5: Drain and sewer systems outside buildings - Part 5: Rehabilitation (11.1997) DIN EN 13380: General requirements for components used for renovation and repair of drain and sewer systems outside buildings (10.2001) DIN EN 13566: Plastics piping systems for renovation of underground non-pressure drainage and sewerage networks

Part 1: General (04.2003);

Part 2: Lining with continuous pipes (02.2006)

Partl 3: Lining with … |

|

|

|

Lining with close-fit pipes - PE- or PVC-lining pipes are used in particular.

- Pulling-in a plastic continuous pipe (lining pipe), whose cross-sectional dimensions have been reduced by predeformations, into the section to be rehabilitated.

- Subsequent expansion until it clings to the interior wall of the sewer.

- Minimising the cross section reduction of the section that has to be rehabilitated compared to the lining with continuous pipes with annular …

|

|

|

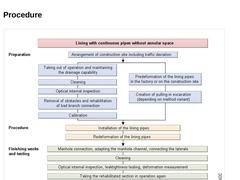

| (Image: Sequence diagram for renovation of drains and sewers with prefabricated pipes - Lining with continuous pipes without annular space)

|

|