|

|

Depending on the type of deformation and reversion of the plastic continuous pipe, one generally distinguishes in principle between the deformation and the reduction processes . | Deformation process (Image: Compact pipe process with reference to [FI-Wavin] - Pulling-in the C-shaped folded continuous pipe [Image: S&P GmbH])

| Reduction process (Image: Reduction process with thermal-mechanical diameter reduction (Swagelining) with reference to [FI-Advan] - … |

|

|

|

The lining with continuous pipes without annular space requires the following equipment: - Staff of 4-6 persons on construction site

- Possibly devices and machines for installing and securing the excavation (e.g. excavator, lining elements)

- Heating element butt welding equipment and power set, if required

- Winch with corresponding tensile strength

- Pulling head

- Roller blocks

- Lifting device

- Reduction unit, if required

- Steam generator, if required

- Compressor …

|

|

|

|

|

|

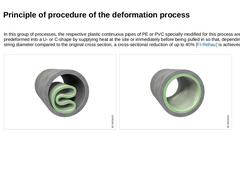

In this group of processes, the respective plastic continuous pipes of PE or PVC specially modified for this process are predeformed into a U- or C-shape by supplying heat at the site or immediately before being pulled in so that, depending on the string diameter compared to the original cross section, a cross-sectional reduction of up to 40% [FI-Rehau] is achieved. | |

(Image: Deformation process – lining pipe pre-deformed)

|

(Image: Deformation process - … |

|

|

|

| (Image: Limiting conditions)

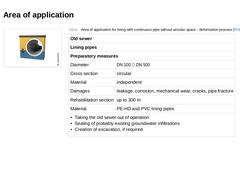

| (Table: Area of application for lining with continuous pipe without annular space - deformation process [FI-Steina]) |

|

|

|

|

|

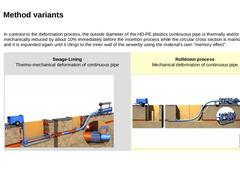

In contrast to the deformation process, the outside diameter of the HD-PE plastics continuous pipe is thermally and/or mechanically reduced by about 10% immediately before the insertion process while the circular cross section is maintained, and it is expanded again until it clings to the inner wall of the sewerby using the material's own "memory effect". | Swage-Lining

Thermo-mechanical deformation of continuous pipe (Image: Reduction process with thermal-… |

|

|

| (Image: Reduction process with mechanical diameter reduction (Rolldown process) with reference to [FI-Klug] - Sketch of the principle [Image: S&P GmbH])

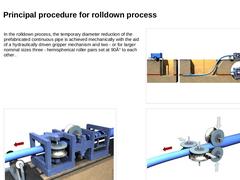

In the rolldown process, the temporary diameter reduction of the prefabricated continuous pipe is achieved mechanically with the aid of a hydraulically driven gripper mechanism and two - or for larger nominal sizes three - hemispherical roller pairs set at 90° to each other . | | (Image: Deformation … |

|

|

|

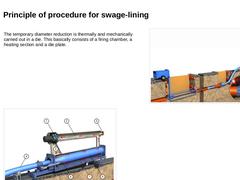

The temporary diameter reduction is thermally and mechanically carried out in a die. This basically consists of a firing chamber, a heating section and a die plate. | (Image: Reduction process with thermal-mechanical diameter reduction (Swagelining) with reference to [FI-Teerb] - View on the starting excavation [Image: S&P GmbH])

| | (Image: Reduction process with thermal-mechanical diameter reduction (Swagelining) with reference to [FI-Teerb] - View … |

|

|

| (Image: Limiting conditions)

| (Table: Area of application for lining with continuous pipe without annular space - Reduction process [FI-Steina]) |

|

|

|

|

The lecture describes the two different method variants, deformation process and reduction process, as well as their areas and limits of application. |

|

The lecture "Lining with continuous pipes with annular space" describes the different method variants and systems as well as their areas and limits of application. The aim of this lecture is to give an overview of the execution of these measures including the relevant preparatory and finishing works. |

|

|

According to EN 752-5 [DINEN752-5:1995], renovation is understood to be measures aimed at improving the current functionality of sewage pipes and sewers under full or partial inclusion of their original substance. | |

The measures used for carrying this out are : - Coating processes and

- Lining processes .

| (Image: Damages)

|

|

|

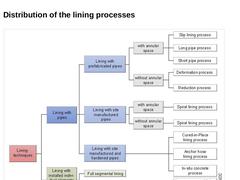

| (Image: Distribution of the lining processes)

|

|

|

|

|

|

Full linings serve the purpose of replacing or enhancing the resistance properties to physical, chemical, biochemical and/or biological attacks, for hindering the renewed formation of incrustations, for replacing and/or increasing the static bearing capacity as well as the leaktightness. | |

(Image: Structural calculation)

|

|

(Image: Leaktightness)

|

|

|

|

|

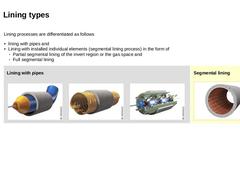

Lining processes are differentiated as follows - lining with pipes and

- Lining with installed individual elements (segmental lining process) in the form of

- Partial segmental lining of the invert region or the gas space and

- Full segmental lining

| Lining with pipes |

(Image: Lining with prefabricated pipes)

|

(Image: Lining with site manufactured pipes)

|

(Image: Lining with site manufactured and hardened pipes)

|

| Segmental lining (Image: Segmental lining)

|

|

|

The lining with pipes is understood to be, similar to (not found),the creation of self-supporting full lining of sewer sections based on -

Prefabricated pipes;

-

Site manufactured pipes; and

-

Site manufactured and hardened pipes.

(Image: Depiction of the lining with site manufactured pipes (spiral lining process) using the RIB-LOC-Relining-System as an example with reference to [FI-RIBLOb] - Sketch of principle [Image: S&P GmbH]) (Image: Insertion of … |

|

|

|

|

Lining with prefabricated pipes is characterised by the pulling, pushing or driving-in of pipes (also lining pipes) into the section of the sewer to be rehabilitated. One differentiates between: - Lining with continuous pipes

- Lining with discrete pipes

|

(Image: Conventional sliplining process with annular space with reference to [FI-Teerb] - Depiction of principle [Image: S&P GmbH])

|

(Image: Discrete pipe method - Pulling-in of discrete pipes into the … |

|

|

|

|

|

DIN EN 13566 Lining with continuous pipes Lining with continuous pipes:

Lining with pipe made continuous for the length of the section to be renovated prior to insertion, and which has not been shaped to give it a cross-sectional diameter smaller than its final diameter after installation [DINEN13566-1:2003]. | | (Image: Conventional sliplining process with annular space with reference to [FI-Teerb] - Depiction of principle [Image: S&P GmbH]) |

|

|

DIN EN 13566 | Lining pipe Lining pipe:

Pipe to be inserted for renovation purposes [DINEN13566-1:2003]. | Liner Liner:

Lining pipe after installation [DINEN13566-1:2003]. | Lining system Lining system:

Lining pipe and all relevant fittings for insertion into an existing pipeline for the purposes of renovation [DINEN13566-1:2003]. |

|

|

|

European standards: DIN EN 752-5: Drain and sewer systems outside buildings - Part 5: Rehabilitation (11.1997) DIN EN 13380: General requirements for components used for renovation and repair of drain and sewer systems outside buildings (10.2001) DIN EN 13566: Plastics piping systems for renovation of underground non-pressure drainage and sewerage networks

Part 1: General (04.2003);

Part 2: Lining with continuous pipes (02.2006)

Partl 3: Lining with … |

|