|

|

Conventional sliplining process (Image: Conventional sliplining process with annular space [FI-Teerb] - View of the pulling-in excavation with continuous pipe)

excavation required (Image: Conventional sliplining process with annular space with reference to [FI-Teerb] - Depiction of principle [Image: S&P GmbH]) |

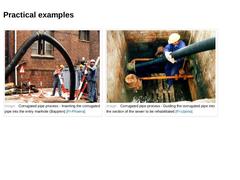

Corrugated pipe process (Image: Corrugated pipe process - Inserting the corrugated pipe into the entry manhole (Baypren) [FI-Phoena])

installation … |

|

|

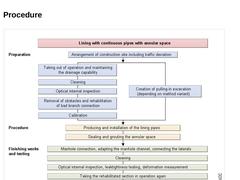

| (Image: Sequence diagram for the lining with continuous pipes with annular space)

|

|

|

| (Image: Equipment for lining with prefabricated pipes with anular space)

The lining with continuous pipes with annular space requires the following equipment: - Staff of 4-6 persons on construction site

- Possibly devices and machines for installing and securing the excavation (e.g. excavator, supporting elements)

- Heating element butt welding equipment and power set

- Winch with corresponding tensile strength

- Pulling head

- Roller blocks

- Lifting device

- Compulsory …

|

|

|

|

|

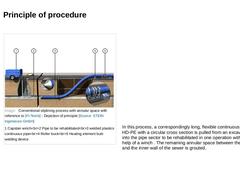

| (Image: Conventional sliplining process with annular space with reference to [FI-Teerb] - Depiction of principle [Image: S&P GmbH]) In this process, a correspondingly long, flexible continuous pipe of HD-PE with a circular cross section is pulled from an excavation into the pipe sector to be rehabilitated in one operation with the help of a winch . The remaining annular space between the liner and the inner wall of the sewer is grouted. |

|

|

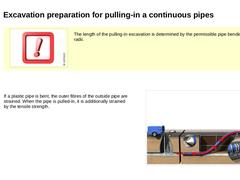

| (Image: Attention!)

The length of the pulling-in excavation is determined by the permissible pipe bending radii. | |

If a plastic pipe is bent, the outer fibres of the outside pipe are strained. When the pipe is pulled-in, it is additionally strained by the tensile strength. | (Image: Loads of outer fibres of the continuous pipe when pulled in)

|

|

|

|

|

A further representative of the sliplining process is the corrugated or spiral pipe process (not found), which the manufacturer of the special three-layer pipes has designated as the "Flexoren Process". |

|

(Video: Corrugated pipe - Pulling-in of the inliner into the section to be rehabilitated) |

|

A pull head is attached to the end of the continuous pipe in order to make the pulling-in process easier and an insertion funnel is placed at the start of … |

|

|

|

(Image: Corrugated pipe process - Inserting the corrugated pipe into the entry manhole (Baypren) [FI-Phoena])

|

(Image: Corrugated pipe process - Guiding the corrugated pipe into the section of the sewer to be rehabilitated [FI-Upono])

|

|

|

|

|

|

|

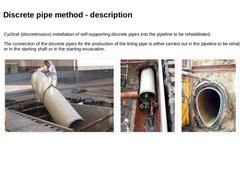

Cyclical (discontinuous) installation of self-supporting discrete pipes into the pipeline to be rehabilitated. The connection of the discrete pipes for the production of the lining pipe is either carried out in the pipeline to be rehabilitated or in the starting shaft or in the starting excavation. |

(Image: Installation of a GRP-discrete pipe into the starting excavation)

|

(Image: Taking-up and driving -in of the GRP pipes: step 2)

|

(Image: Driving-… |

|

|

|

|

|

The lecture describes the different method variants and systems of lining with prefabricated pipes with annular space especially the lining with continuous and discrete pipes. |

|

The renovation of sewers and pipelines with "Lining with cured-in-place pipes" is an established standard construction method, starting with the planning process, through material production and installation, right up to checking the quality achieved. It is characterized by a wide range of applications and a high variance in the fabrication and application processes.

This module teaches the essential basics in relation to the fabrication of the lining tube and its installation.

After completing this module, you will have a sound knowledge of:

- range of application of tube lining

- damage patterns and application limits;

- requirements on materials, resin systems and carrier material;

- curing processes and procedures.

|

|

|

|

|

|

|

|

In the following, special attention is paid to integral solutions. They include: -

the protection of the existing fabric of sewer by suitable linings or internal coatings

-

the rehabilitation of the pipe structure.

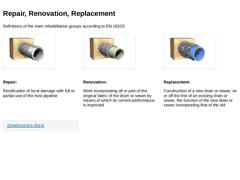

The rehabilitation of the existing fabric of sewer can be carried out by the main rehabilitation groups repair, renovation or replacement. (Image: Picto Repair connections) (Image: Picto Renovation) (Image: Picto Replacement) |

|

Definitions of the main rehabilitation groups according to EN 16323: (Image: Repair (Rectification of local damage) (Image: Lining with cured-in-place pipes) (Image: Replacement using trenchless technology (pipe bursting) ) Repair: Rectification of local damage with full or partial use of the host pipeline Renovation: Work incorporating all or part of the original fabric of the drain or sewer by means of which its current performance is improved |

|

Often it is more cost effective to repair localised damage, referred to as point repair. Multiple point repair and/or extensive damage can be rehabilitated either by renovation or by replacement. If hydraulic overloading or a reduction in cross section caused by renovation measures cannot be accepted, then only replacement comes into question. (Image: Locally limited damage) (Image: Repeated and extensive damage) (Image: Hydraulic overloading) |

|

The diagram represents a simplified decision-making process for the selection of the structural solution for a rehabilitation. The decision-making process is limited here to the aspects -

technological feasibility

-

economic viability and

-

hydraulic load.

(Image: Decision process for the selection of structural solutions with reference to DIN EN 752-5 [DINEN752-5b]) |

|

|

|

In the case of lining techniques sectional self-supporting full linings of sewers are manufactured on the basis of (Image: Lining with prefabricated pipes) (Image: Lining with site manufactured pipes) (Image: Lining with site manufactured and hardened pipes) "Lining with cured-in-place pipes" belongs to the group of lining techniques with site manufactured and … |

|

Full linings serve to restore or increase the resistance against physical, chemical, biochemical and/or biological attacks, to prevent the formation of new incrustations, to restore and/or increase the static load-bearing capacity and water tightness. |

(Image: Picto Wastewater Type) |

Restoring or increasing resistance to physical, chemical, biochemical and/or biological attacks |

|

(Image: Picto Statik) |

Restoration or increase of the static load-bearing … |

|

|

A distinction is made between the lining techniques: -

Lining with pipes (full lining) and

-

Lining with prefabricated segments in the form of

-

Partial segment lining at invert

-

Partial segment lining of the pipe invert or gas space

-

Full segment lining

Full lining (Image: Lining with prefabricated pipes) (Image: Lining with site manufactured pipes) (Image: Lining with site manufactured and hardened pipes) Lining with prefabricated segments (Image: Picto … |