|

Basierend auf Praxiserfahrungen sollten zur Sicherstellung einer fachgerechten Anwendung der Hochdruckreinigung und zur Vermeidung von Schäden folgende Hinweise und Empfehlungen beachtet werden: -

Bei der Wahl der Betriebsparameter (Düsenart, Durchfluss, Abstrahlwinkel, Druck an der Düse) sollten neben den sich aus der eigentlichen Reinigungsaufgabe ergebenden Parametern auch immer der Rohrwerkstoff, die Wanddicke und insbesondere der bauliche Zustand …

|

|

-

Der Druck an der Düse sollte bei schadensfreien Kanälen 120 bar nicht überschreiten. Der zugehörige Pumpendruck ist unter Berücksichtigung der jeweiligen Randbedingungen festzulegen und zu regulieren.

-

Bei schadhaften Kanälen muss mit einem deutlich geringeren Druck an der Düse gearbeitet werden. Dabei kann durch Erhöhung des Abstandes der Düse zur Rohrwandung, z. B. durch Verwendung einer Führungseinrichtung (Kufen oder Schlitten) die Belastung …

|

|

-

Die Reinigungsdüse darf unter keinen Umständen unter Last länger an einer Stelle verweilen, um die Entstehung bzw. Erweiterung von Schäden an Kanälen, insbesondere an den Rohrverbindungen und einragenden Seitenzuläufen, zu vermeiden.

-

Vor Beginn der Reinigungsmaßnahme ist zu überprüfen, ob die Düsenöffnungen verstopft sind, um zusätzliche und unkontrollierte Reaktionskräfte an der Düse und damit verstärkte Beanspruchungen der Rohrwandungen zu vermeiden.

|

|

-

Bei Temperaturen < 0° C sind die Reinigungsfahrzeuge mit Frostschutzverkleidungen zu versehen, um das Zufrieren von Pumpen und Leitungen zu verhindern. Die Verkleidungen können auch Lärmschutzfunktionen übernehmen.

-

Kunststoffschläuche sind aufgrund ihrer besseren hydraulischen Eigenschaften und aus Gewichtsgründen den Gummischläuchen vorzuziehen. Allerdings sollten die ersten 10 bis 20 m aus Gummischlauch ausgeführt werden, da dieser flexibler …

|

|

Bei der Hochdruckreinigung treten außerdem oftmals starke Luftströmungen auf. Diese Wechselwirkung erzeugt einen mehr oder weniger großen Drucksprung an der Düse, d. h. vor der Düse entsteht ein Unterdruck (Düsenkopf) und hinter der Düse (Strahlbereich) ein Überdruck. Beim Passieren der Reinigungsdüse an Seitenzuläufen (Hausanschlüssen), kann es dadurch zu Ausblasungen bzw. zur Absaugung von Sperrwasser aus Geruchsverschlüssen der Hausinstallationen (… |

|

Folgende Maßnahmen können die Gefahren der Geruchsbelästigungen minimieren: -

Reduzierung des Pumpendruckes am Fahrzeug (damit auch kleinerer Spüldruck)

-

Auswahl der richtigen Reinigungsdüse (große Strahlwinkel, geringe Anzahl von Düseneinsätzen)

-

Reduzierung der Rückzuggeschwindigkeit der Düse

-

Reinigung möglichst kurzer Abschnitte von Schacht zu Schacht,

-

regelmäßiges Entfernen des Räumgutes innerhalb einer Haltung und

-

Verbesserung der Luftzufuhr …

|

|

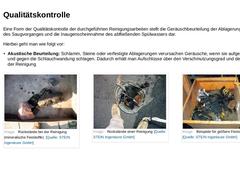

Eine Form der Qualitätskontrolle der durchgeführten Reinigungsarbeiten stellt die Geräuschbeurteilung der Ablagerungen während des Saugvorganges und die Inaugenscheinnahme des abfließenden Spülwassers dar. Hierbei geht man wie folgt vor: -

Akustische Beurteilung: Schlamm, Steine oder verfestigte Ablagerungen verursachen Geräusche, wenn sie aufgesaugt werden und gegen die Schlauchwandung schlagen. Dadurch erhält man Aufschlüsse über den Verschmutzungsgrad …

|

|

Visuelle Beurteilung: Durch Inaugenscheinnahme der Beschaffenheit bzw. Färbung des abfließenden Spülwassers lassen sich Rückschlüsse auf die Reinigungsergebnisse ziehen. (Bild: Kontrolle der Reinigungsarbeit) (Bild: Schacht Reinigung Kontrolle) Weitere Leistungsindikatoren für die Beurteilung der Reinigungsarbeit sind in DIN EN 14654-1 enthalten. |

|

|

|

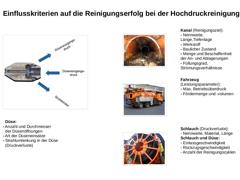

(Bild: Radialdüse Querschnitt) Düse:

- Anzahl und Durchmesser der Düsenöffnungen - Art der Düseneinsätze - Strahlumlenkung in der Düse (Druckverluste) (Bild: Ablagerungen Abwasserkanal-Mischungen aus organischen und mineralischen Stoffen) Kanal (Reinigungsziel):

- Nennweite, Länge,Tiefenlage - Werkstoff - Baulicher Zustand - Menge und Beschaffenheit der An- und Ablagerungen - Füllungsgrad, Strömungsverhältnisse (Bild: Spül Saugfahrzeug Stadt Bochum) Fahrzeug… |

|

Herzlichen Glückwunsch! Hiermit haben Sie die vorliegende Lektion erfolgreich beendet. Im Anschluss haben Sie nun die Möglichkeit, das neu erlangte Wissen mithilfe eines interaktiven Fragebogens selbstverantwortlich zu überprüfen. Natürlich können Sie außerdem nach wie vor zu einem beliebigen Punkt in den vergangenen Lektionen zurücknavigieren, um das eine oder andere Thema oder Detail erneut anzuschauen. Bleiben Sie neugierig! |

|

|

|

Wesentlicher Bestandteil der Hochdruckreinigung sind die Reinigungsdüsen. Die Wahl der optimalen Reinigungsdüse für den jeweiligen Anwendungsfall ist eine komplexe Aufgabenstellung, da hier eine Vielzahl an Düsentypen mit unterschiedlichsten Ausstattungsmerkmalen zur Verfügung steht. Nach Abschluss dieser Lektion verfügen Sie über fundierte Kenntnisse bezüglich: - der physikalischen Wirkungsweise von Druckwasserstrahlen;

- der Auswahl von Reinigungsdüsen in Abhängigkeit der Reinigungsaufgabe und

- der Einschätzung und dem Erkennen von Einsatzrisiken.

|