|

With the Weco-Seal process and the Amex-10 System it is possible to seal pipe joints, lateral and longitudinal cracks in all types of piping and materials except rectangular cross sections and masonry sewers. The sealing sleeves are elastic and thus relatively insensitive to small positional deviations. Disadvantages: - The process can only be applied in man-accessible piping with smooth internal surfaces;

- The time required is relatively high especially …

|

|

|

|

|

|

In non-man-accessible as well as in man-accessible sewers, localized damage and/or affected sections of the sewer can be sealed or statically stabilized by the insertion of internal sleeves. The processes can be divided into the following groups: - Short hose process (also called shortliner process):

- Short hoses based on synthetic resin (GRP short hoses) (Abschnitt 5.2.3.2.3.1)

- Short hoses based on cement as binder (Abschnitt 5.2.3.2.3.2)

- Internal sleeves …

|

|

|

|

Sealing processes are understood to be locally limited measures for replacing the leaktightness and, if necessary, the bearing strength. They are concerned mainly with: - Sealing from outside

- Shrink hoses (Abschnitt 5.2.3.1.1)

- External sleeves (Abschnitt 5.2.3.1.2)

- Sealing from inside

- Surface treatment (Abschnitt 5.2.3.2.1)

- Sealing substances (Abschnitt 5.2.3.2.2)

- Internal sleeves (Abschnitt 5.2.3.2.3)

Sealing from outside requires the digging of an … |

|

(Image: Overview of the repair processes) According to EN 752-5 [DINEN752-5:1997], repair is understood to be measures to rectify local damages. These repair processes (Bild 5.2) include: - Restoration (Abschnitt 5.2.1) ;

- Injection processes (Abschnitt 5.2.2) ;

- Sealing processes (Abschnitt 5.2.3).

Repairs from outside are carried out to manhole structures as well as to the sewer itself. They require, among others the digging of an excavation. Repairs from … |

|

Feb 16, 2011

News

TT-UK Ltd

The renewal of sewage pipes with the TIP method through a manhole has been extended by a further technically advanced variation.

|

|

|

According to EN 752-5 [DINEN752-5:1997], repair is understood to be measures to rectify local damages. (Image: Repair)

|

|

|

The lecture series "Repair of manholes made of concrete, reinforced concrete and masonry" presents several possibilities for repairing manholes. The fourth part of the series is about rehabilitation of cracks in manholes by means of injection. The aim of the lecture is to provide an overview of implementation of such measures. |

|

|

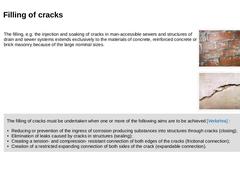

The filling, e.g. the injection and soaking of cracks in man-accessible sewers and structures of drain and sewer systems extends exclusively to the materials of concrete, reinforced concrete or brick masonry because of the large nominal sizes. | |

(Image: Crack formation in the masonry)

|

|

(Image: Crack formation in the concrete)

|

| |

The filling of cracks must be undertaken when one or more of the following aims are to be achieved [Verkehra] : |

|

|

|

The process that is applied for the filling of cracks is differentiated according to the pressures used for inserting the filler into the crack as follows: - Soaking (S): filling without pressure to close the crack;

- Injection (I): filling under pressure using filling nozzles (injection packers) for all the application purposes mentioned above.

| | |

The filler materials for both types of filling are mostly epoxy resins (EP) and polyurethane resins (PUR). |

|

|

|

|

|

|

|

In crack injection, the introduction of the injection media is achieved with low pressure apparatus (up to 20 bar) or high pressure apparatus (up to 250 bar) by means of an injection packer. The injection apparatus consists of: - a pressure generator,

- material container,

- transport hose,

- connection piece for the injection packer and,

- mixing and dosing aggregates, if required.

| |

(Image: Pressure vessel for transporting the injection mortar)

|

(Image: Installed … |

|

|

|

| (Image: Single-component injection in the masonry)

Single-component injection In the single-component injection, the injection medium is pre-mixed and injected by the injection apparatus. | | | (Image: Two-component injection in the masonry)

Two-component injection In the two-component injection, the individual components are conveyed up to a mixer connected immediately in front of the injection packer and injected into the crack after mixing. In this way, … |

|

|

|

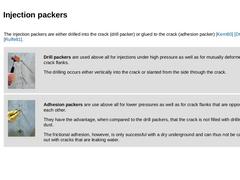

The injection packers are either drilled into the crack (drill packer) or glued to the crack (adhesion packer) [Kern80] [DGEG86b] [Ruffe81]. | | (Image: Working sequence for a crack injection with tight connection [FI-Sto] - Injection with drilling packers arranged vertically in the crack - Hammering the packer in)

Drill packers are used above all for injections under high pressure as well as for mutually deformed crack flanks. The drilling occurs either … |

|

|

| (Image: Injection packer for crack injection with reference to [Werse88] [Image: S&P GmbH] - Drilling packer)

| (Image: Ribbed impact packer 18 - 105 m [FI-Desoi])

| | (Image: Quick-acting snap connection [FI-Desoi])

| (Image: Crack injection by means of drill packer)

|

|

|

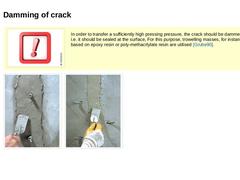

| (Image: Attention!)

In order to transfer a sufficiently high pressing pressure, the crack should be dammed up, i.e. it should be sealed at the surface, For this purpose, trowelling masses, for instance based on epoxy resin or poly-methacrlylate resin are utilised [Grube90]. | | |

(Image: Working sequence for a crack injection with tight connection [FI-Sto] - Injection with drilling packers arranged vertically in the crack - Damming)

|

(Image: Working … |

|

|

|

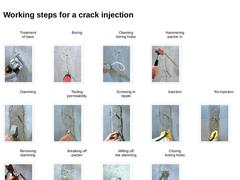

Treatment

of base (Image: Working sequence for a crack injection [FI-Sto] - Base pre-peration)

| Boring

(Image: Working sequence for a crack injection with tight connection [FI-Sto] - Injection with drilling packers arranged vertically in the crack - Boring)

| Cleaning

boring holes (Image: Working sequence for a crack injection with tight connection [FI-Sto] - Injection with drilling packers arranged vertically in the crack - Cleaning boring holes)

| Hammering |

|

|

|

|

| | (Image: Attention!)

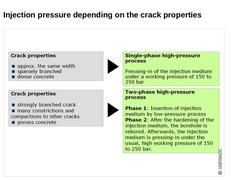

In order to prevent damage to concrete structures, the injection pressure according to [Asend88] should be confined to a maximum of 33 % of the cube strength of the concrete. |

|

|

| (Image: Injection pressure depending on the crack properties)

|

|

|

|

|

| (Image: Infiltration)

|

Huge water infiltrations into concrete and reinforced concrete manholes can be sealed by injections in accordance with [DGEG86b] : - damming of water infiltrations by means of single-component polyurethane foam

- injection by means of two-component polyurethane resin

- second injection by means of two-component polyurethane resin.

|

|