|

Over the past few years several special nozzle types were developed in addition to the standard nozzles in order to widen the high-pressure sewer cleaning range of applications. |

|

This nozzle is intended to compensate for the disadvantage of the flat jet nozzles, whose cleaning focus is not always fully on the channel bottom because it tends to slide up the channel wall. The jets are located bellow the horizontal axis of the nozzle in order to directly discharge the water into the channel bottom. The Pendulum nozzle is kept in an optimal cleaning position by its low centre of gravity, and a flexible … |

|

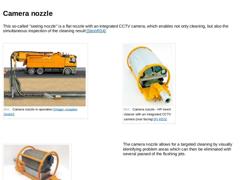

This so-called "seeing nozzle" is a flat nozzle with an integrated CCTV camera, which enables not only cleaning, but also the simultaneous inspection of the cleaning result [SteinR04]. (Image: Camera nozzle in operation) (Image: Camera nozzle - HP invert cleaner with an integrated CCTV camera (rear facing)) (Image: Invert nozzle with an integrated CCTV camera) The camera nozzle allows for a targeted cleaning by visually identifying problem areas which … |

|

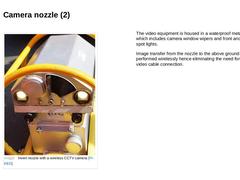

(Image: Invert nozzle with a wireless CCTV camera) The video equipment is housed in a waterproof metal housing which includes camera window wipers and front and rear facing spot lights. Image transfer from the nozzle to the above ground receiver is performed wirelessly hence eliminating the need for a direct video cable connection. |

|

Additional equipment needed for the operation of the video camera and documentation of the cleaning operation (video recorder, monitor, battery charger) can be installed directly on the cleaning vehicle, or in a separate service vehicle. (Image: Camera nozzle monitoring equipment) (Image: Invert nozzle detail) (Image: Camera nozzle being lowered into the sewer manhole) |

|

(Video: Pipe damage identified using the seeing nozzle) Video: Pipe damage identified using the seeing nozzle (DN 400 clay pipe) [FI-KEG]. This object is only visible in the online version of the module. (Video: Inspection of the cleaning performance using the seeing nozzle in a concrete channel) Video: Inspection of the cleaning performance using the seeing nozzle in a concrete channel [FI-KEG]. This object is only visible in the online version of … |

|

(Table: Camera nozzle - manufacturer specifications (2002)) |

|

Based on a similar concept is the "Seeing North Sea nozzle" for the nominal diameter range DN 100 to DN 1000. In this case, it is a radial nozzle with a front camera allowing a look forward. (Image: "Seeing North Sea nozzle") (Image: "Seeing North Sea nozzle") (Image: "Seeing North Sea nozzle") (Image: "Seeing North Sea nozzle") |

|

|

|

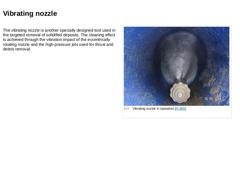

The vibrating nozzle is another specially designed tool used in the targeted removal of solidified deposits. The cleaning effect is achieved through the vibration impact of the eccentrically rotating nozzle and the high-pressure jets used for thrust and debris removal. (Image: Vibrating nozzle in operation) |

|

For a number of years now, high-pressure cleaning has been combined with ejector technology in the form of ejector nozzles (also called injector nozzles) |

|

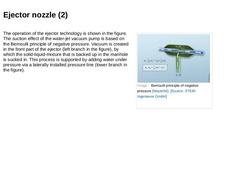

The operation of the ejector technology is shown in the figure. The suction effect of the water-jet vacuum pump is based on the Bernoulli principle of negative pressure. Vacuum is created in the front part of the ejector (left branch in the figure), by which the solid-liquid-mixture that is backed up in the manhole is sucked in. This process is supported by adding water under pressure via a laterally installed pressure line (lower branch in the figure). |

|

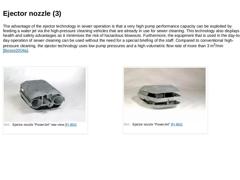

The advantage of the ejector technology in sewer operation is that a very high pump performance capacity can be exploited by feeding a water jet via the high-pressure cleaning vehicles that are already in use for sewer cleaning. This technology also displays health and safety advantages as it minimises the risk of hazardous blowouts. Furthermore, the equipment that is used in the day-to-day operation of sewer cleaning can be used without the need … |

|

The ejector nozzle directs its kinetic energy towards the sewer invert. Thus, full contact between the pressurised water jets and the pipe wall is avoided. In specialist circles, this approach is also called "soft cleaning". (Image: Ejector nozzle - top view) |

|

To use an ejector nozzle, the cleaning vehicle must generate a volumetric flow rate of at least 320 l/min and a pump pressure of 150 bar. The water pressure at the nozzle, subsequently called nozzle pressure, must be between 40 to 60 bar to propel the relatively heavy nozzle. Compared to conventional high-pressure cleaning methods, using the ejector increases the volumetric flow rate of the pump by 3 to 5 times [FI-enz]. Ejector nozzles are used in … |

|

|

|

|

|

|

|

High-pressure nozzles are equipped with interchangeable jetting inserts which help to extend the nozzles service life, and make it more versatile by being adaptable to different water flow and pressure rates. The inserts are easily screwed into the threaded bores of the nozzle. The nozzle inserts differ in: |

|

(Image: Ceramic nozzle inserts (JetMax, ceramic, max. 500 bar)) The cleaning nozzles inserts are made of -

Stainless steel

-

Sapphire

-

Ceramic

Ceramic and sapphire inserts show very low wear and have a high flow rate hence making them optimal in use with high-pressure cleaning vehicles with water reclamation technology. (Table: Nozzle inserts – Materials) |

|

Sapphire and ceramic have proven to be very wear resistant materials, however, ceramics inserts have shown to have a longer life span when used with very contaminated flushing water. -

Titanium Ceramic: This ceramic is comprised of nearly pure alumina. The additions of titanium oxide and other additives produces a very fine grain structure that exhibits higher strength values than pure oxide ceramic (Al2O3).

|

|

|

|

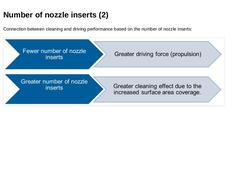

The nozzle inserts have a bore diameter of 0.3 to 4.0 mm or more. The number of nozzle inserts can be both even or odd. In the case of an odd number, only equally sized hole diameters are to be used to prevent the nozzle from drifting off in one direction. When using different hole diameters, their number has to be even and symmetrically placed. |

|

Connection between cleaning and driving performance based on the number of nozzle inserts: (Image: Number of nozzle inserts) |

|

|