|

|

(Image: Attention!)

According to DIN 4124, the stability of unlined walls must be verified with the calculation method of DIN 4084 or by a subsoil report. The introduction of the jacking forces into the slope wall must also be specially proven to be safely arranged. [DIN4124:2012] [DIN4084:1997] |

|

(Image: Unlined, sloped starting shafts - In microtunnelling with hydraulic spoil removal [FI-Herreb]) |

With increasing depth, the excavation volumes … |

|

|

Prerequisites for the use of unlined shafts: -

observation of a minimum clearance between slope edge and vehicles/construction machinery (load-free protective strip at the slope edge)

-

no effect of dynamic loads

-

no flow of strata water into the shaft

-

no fissures or dislocation in rock

|

|

| (Image: Pros and cons) |

Advantages of unlined shafts: - simple creation

- special devices are not necessary

- lining material not necessary

- noise-free and vibration-free method of construction

- use of large machinery for excavation as well as the building of the structure is possible without impediments as no bracing structures are necessary

- compaction of the backfilling against the in-situ soil

|

Disadvantages of unlined shafts: - great space requirements…

|

|

|

|

|

|

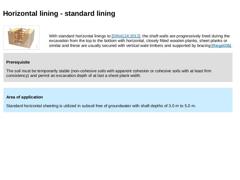

(Image: Standard horizontal lining to DIN 4124 (means of fixing not shown) with reference to [DIN4124c] [Image: S&P GmbH]) |

With standard horizontal linings to [DIN4124:2012], the shaft walls are progressively lined during the excavation from the top to the bottom with horizontal, closely fitted wooden planks, sheet planks or similar and these are usually secured with vertical wale timbers and supported by bracing [Riege00b]. |

|

|

Prerequisite The … |

|

|

Removable (or reusable) linings in trenchless installation are understood to be coverings and bracings which, after completion of the jacking works, can be removed without danger by filling up the shaft again and which do not remain in the subsoil permanently. Types of removable linings are: -

horizontal lining

-

vertical lining

-

lining systems

-

supporting planks wall

(Image: Standard horizontal lining to DIN 4124 (means of fixing not shown) with reference … |

|

| (Image: Pros and cons) | | Advantages of standard horizontal lining: - light lining elements

- good adaptability especially with crossing pipelines

- frequent re-use possible

- compaction of the backfill against the in-situ soil

| | Disadvantages of standard horizontal lining: - soft lining, danger of subsidence for neighbouring structures or traffic surfaces

- wage and time intensive due to manual activities

- limited space for movement due to close bracers spacing…

|

|

|

|

(Image: Shaft supporting based on 2-flange liner plates using as an example the products of the HAMCO company [FI-Hamco] - View) (Image: Shaft supporting based on 4-flange liner plates ) |

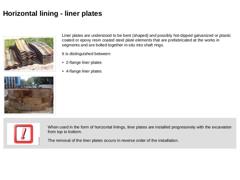

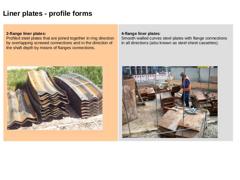

Liner plates are understood to be bent (shaped) and possibly hot-dipped galvanized or plastic coated or epoxy resin coated steel plate elements that are prefabricated at the works in segments and are bolted together in-situ into shaft rings. It is distinguished between: |

|

|

|

2-flange liner plates:

Profiled steel plates that are joined together in ring direction by overlapping screwed connections and in the direction of the shaft depth by means of flanges connections. (Image: Shaft supporting based on 2-flange liner plates using as an example the products of the HAMCO company [FI-Hamco] - View) |

4-flange liner plates:

Smooth-walled curves steel plates with flange connections in all directions (also known as steel sheet … |

|

|

|

Insertion method (liner plates): (Image: Shaft supporting based on 2-flange liner plates using as an example the products of the HAMCO company [FI-Hamco] - Lining section installed in a building pit)

Areas of application of the insertion method when using liner plates: -

(temporarily) stable soils

|

Sinking method (liner … |

|

|

| (Image: Pros and cons) | Advantages of liner plates: - light lining elements

- liner plates can be assembled and disassembled without lifting gear

- frequent re-use is possible

- stiffness allows for the complete pre-assembly and sinking of the shaft

- liner plates stackable

- economically efficient

|

|

|

|

(Image: Example of a vertical trench lining with sheet planks with reference to [DIN4124c] [Image: S&P GmbH]) |

With standard vertical lining to DIN 4124, wooden planks or sheet planks are progressively installed with the excavation or, in soft cohesive soil, are first driven vertically into the soil so that in all construction state, their points are at least 0.30 m in the soil [DIN4124:2012].

The earth or traffic loads acting on the vertical wooden … |

|

|

| (Image: Pros and cons) | Advantanges of standard vertical lining: - high degree of mechanisation in installing the lining

- relatively little braces and therefore greater freedom of movement

- excavation generally occurs after the installation of the lining giving better security for personnel

- no minimum requirements for the stability of the soil

|

| | (Image: Pros and cons) | Disadvantages of standard vertical lining: - high material costs

- soil must be capable …

|

|

|

|

(Image: Shaft support based on sheet planks or sheet piles - Sheet planks profile (Profile type ARBED RC) [FI-ISPC] [FI-Krupp]) (Image: Sheet pile profile "system Larssen" with reference to [HSP06] [Image: S&P GmbH]) The steel sheet planks or sheet piles with wall thicknesses between 3 mm and 8 mm are driven into the soil by means of ramming, vibration (shaking) or pressing into the soil [EAU1990] [DIN18304] [DINEN12063] [Lackn97]. The choice of the … |

|

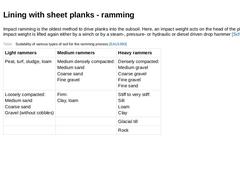

Impact ramming is the oldest method to drive planks into the subsoil. Here, an impact weight acts on the head of the plank. The impact weight is lifted again either by a winch or by a steam-, pressure- or hydraulic or diesel driven drop hammer [Schne95]. (Table: Suitability of various types of soil for the ramming process [EAU1990]) |

|

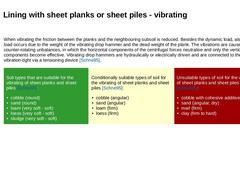

When vibrating the friction between the planks and the neighbouring subsoil is reduced. Besides the dynamic load, also a static load occurs due to the weight of the vibrating drop hammer and the dead weight of the plank. The vibrations are caused by counter-rotating unbalances, in which the horizontal components of the centrifugal forces neutralise and only the vertical components become effective. Vibrating drop hammers are hydraulically or electrically … |

|

|

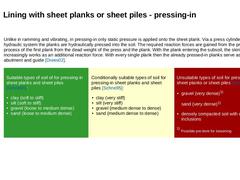

Unlike in ramming and vibrating, in pressing-in only static pressure is applied onto the sheet plank. Via a press cylinder and a hydraulic system the planks are hydraulically pressed into the soil. The required reaction forces are gained from the pressing-in process of the first plank from the dead weight of the press and the plank. With the plank entering the subsoil, the skin friction increasingly works as an additional reaction force. With every … |

|

|

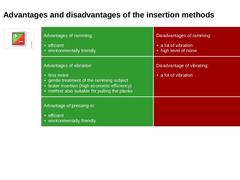

| (Image: Pros and cons) | Advantages of ramming: - efficient

- environmentally friendly

| Disadvantages of ramming: - a lot of vibration

- high level of noise

| | Advantages of vibration: - less noise

- gentle treatment of the ramming subject

- faster insertion (high economic efficiency)

- method also suitable for pulling the planks

| Disadvantage of vibrating: | | Advantage of pressing-in: - efficient

- environmentally friendly

| |

|

|

|

(Image: Pros and cons) |

When compared to sheet planks, sheet piles have the following advantages [Weiße75a]: -

They have greater dimensions and can be rammed much deeper than sheet planks

-

They posses greater section modules so that they can bridge greater support widths

-

They posses interlocking edges and are thus almost watertight

-

Because of the tensile and compressive strengths of the locks, they have a load distributing effect

|

|

|

|

|

(Image: Pros and cons) |

Advantages of sheet pile walls: -

fast progress of construction

-

excavation possible immediately after installing the piles, thus greater safety for the personnel

-

independent of weather

-

lining elements can be reused

-

no minimum requirements of stability of the soil

-

can also be used in groundwater

-

less personnel requirement

-

simple equipment installation

-

transfer of vertical forces via skin friction forces possible

|

|

|

|

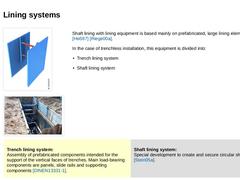

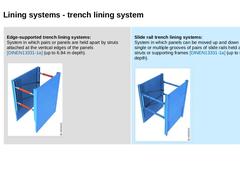

(Image: Centrally supported trench lining system) (Image: Starting pit of lining systems for microtunneling) Shaft lining with lining equipment is based mainly on prefabricated, large lining elements of steel [Heß97] [Riege00a]. In the case of trenchless installation, this equipment is divided into: -

Trench lining system

-

Shaft lining system

|

Trench lining system:

Assembly of prefabricated components intended for the support of the vertical faces of … |

|

|

|

To secure shafts the following trench lining systems are used in the open-cut method of construction: -

edge-supported trench lining systems (type ES)

-

slide rail trench lining systems (type R), single (RS), double (RD) and triple type (RT)

|

|

(Image: Slide rail trench lining system) |

|

(Image: Starting pit with trench lining system ) (Image: Edge-supported trench lining system) |

|

|

(Image: Attention!) |

Trench lining equipment only permits the installation … |

|

|

|

|

Edge-supported trench lining systems:

System in which pairs or panels are held apart by struts attached at the vertical edges of the panels [DINEN13331-1a] (up to 6.84 m depth). (Image: Edge-supported trench lining system)

|

Slide rail trench lining systems:

System in which panels can be moved up and down in single or multiple grooves of pairs of slide rails held apart by struts or supporting frames [DINEN13331-1a] (up to 8.26 m depth). (Image: Slide … |

|

|

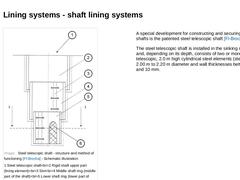

(Image: Steel telescopic shaft - structure and method of functioning [FI-Brocha] - Schematic illustration) A special development for constructing and securing circular shafts is the patented steel telescopic shaft [FI-Brocha]. The steel telescopic shaft is installed in the sinking method and, depending on its depth, consists of two or more telescopic, 2.0 m high cylindrical steel elements (steel rings) of 2.00 m to 2.20 m diameter and wall thicknesses … |

|

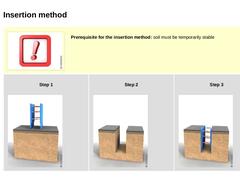

| (Image: Attention!)

Prerequisite for the insertion method: soil must be temporarily stable | | Step 1 (Image: Installation of edge-supported trench lining systems (ES) in the insertion method - Working step 1: Preparation of trench lining system with height corresponding to the depth of the shaft +10 cm and with a width corresponding to that of the shaft)

| Step 2 (Image: Installation of edge-supported trench lining systems (ES) in the insertion method - … |

|