|

|

|

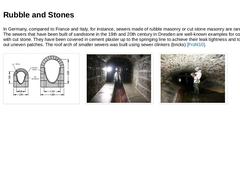

In Germany, compared to France and Italy, for instance, sewers made of rubble masonry or cut stone masonry are rare exceptions. The sewers that have been built of sandstone in the 19th and 20th century in Dresden are well-known examples for constructions with cut stone. They have been covered in cement plaster up to the springing line to achieve their leak tightness and to straighten out uneven patches. The roof arch of smaller sewers was built using … |

|

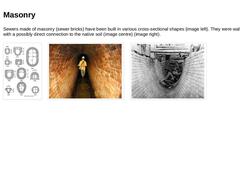

Sewers made of masonry (sewer bricks) have been built in various cross-sectional shapes (image left). They were walled in rings with a possibly direct connection to the native soil (image centre) (image right). (Image: Masonry sewers from the 19th Century still in use in Manchester [Read81]) (Image: Man-accessible masonry sewer) (Image: Construction of masonry sewers in the 19th and 20th century - Bedding in natural soil) |

|

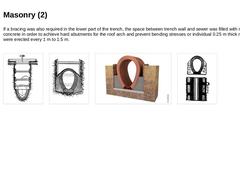

If a bracing was also required in the lower part of the trench, the space between trench wall and sewer was filled with masonry or concrete in order to achieve hard abutments for the roof arch and prevent bending stresses or individual 0.25 m thick masonry pillars were erected every 1 m to 1.5 m. (Image: Construction of masonry sewers [Frühl10] - Bedding in undisturbed soil) (Image: Construction of masonry sewers [Frühl10] - Sewer in complete back … |

|

-

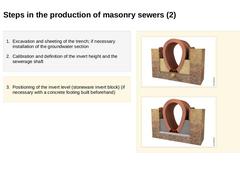

Excavation and sheeting of the trench; if necessary installation of the groundwater section

-

Calibration and definition of the invert height and the sewer shaft

(Image: Example of groundwater retention by installing a longitudinal drainage [Hahn28]) |

|

-

Excavation and sheeting of the trench; if necessary installation of the groundwater section

-

Calibration and definition of the invert height and the sewerage shaft

-

Positioning of the invert level (stoneware invert block) (if necessary with a concrete footing built beforehand)

(Image: Masonry sewer with invert stones and sand filling) (Image: Masonry sewer with invert stones, concrete filling and previously established foundation) |

|

-

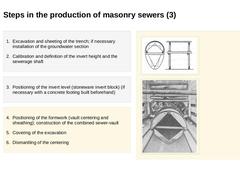

Excavation and sheeting of the trench; if necessary installation of the groundwater section

-

Calibration and definition of the invert height and the sewerage shaft

-

Positioning of the invert level (stoneware invert block) (if necessary with a concrete footing built beforehand)

-

Positioning of the formwork (vault centering and sheathing); construction of the combined sewer-vault

-

Covering of the excavation

-

Dismantling of the centering

|

|

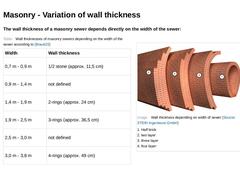

The wall thickness of a masonry sewer depends directly on the width of the sewer: (Table: Wall thicknesses of masonry sewers depending on the width of the sewer according to Braubach) (Image: Wall thickness depending on width of sewer) |

|

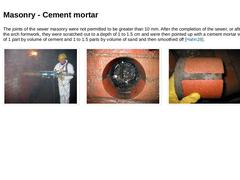

The joints of the sewer masonry were not permitted to be greater than 10 mm. After the completion of the sewer, or after removal of the arch formwork, they were scratched out to a depth of 1 to 1.5 cm and were then pointed up with a cement mortar with a mixture of 1 part by volume of cement and 1 to 1.5 parts by volume of sand and then smoothed off [Hahn28]. (Image: Sampling in a masonry sewer to study the material properties of the brick and cement … |

|

(Image: Construction of a masonry manhole) Since 2000, masonry structures in sewer systems that are newly built or rehabilitated have to be made of sewer bricks of a low porosity that are at least 24 cm thick (one brick) and have fully and evenly filled cement mortar joints without air inclusions. They have to be jointed on their inside (mortar group III with additives) [ATVA157]. The joints are to be smoothed out both on the inside and outside. In … |

|

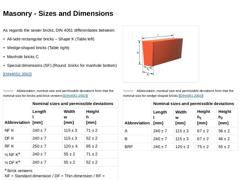

As regards the sewer bricks, DIN 4051 differentiates between: -

All-side rectangular bricks – Shape K (Table left)

-

Wedge-shaped bricks (Table right)

-

Manhole bricks C

-

Special dimensions (SF) (Round bricks for manhole bottom)

[DIN4051:2002] (Image: Wedge-shaped brick according to DIN 4051) (Table: Abbreviation, nominal size and permissible deviations from that the nominal size for bricks and brick veneers) (Table: Abbreviation, nominal size and permissible … |

|

(Image: Vitrified clay pipe - Icon) Pipes made of vitrified clay (formerly called clay pipes) count among the oldest pre-fabricated components in sewer systems. They are manufactured from suitable clays with the addition of fire clays and fired to the stage of sintering [FI-Stein96] [FVS78]. During the firing, a previously applied glazing mass permanently melts with the fragments for inner and, if required, outer glazing, which, contrary to all other … |

|

-

The standard cross section of pipes made of vitrified clay was and still is the circular cross section, which was mainly used for piping DN 100 to DN 600 so far.

-

The graduations of the nominal sizes have remained almost unchanged up to the present. They increase by 25 mm steps up to DN 150, > DN 150 to DN 500 by 50 mm steps, > DN 500 to DN 800 by 100 mm steps and > DN 800 to DN 1400 by 200 mm steps. In the past, in-between sizes were manufactured …

|

|

Vitrified clay pipes are is commonly used in drain and sewer systems because of their resistance to almost all domestic and industrial sewage, particularly the sulfuric acid that is generated by hydrogen sulfide. Only hydrofluoric acid and highly-concentrated caustic wastes are known to attack vitrified clay pipes. |

|

(Image: Reinforced steel pipe Icon) What is concrete? According to Schorn, concrete is a composite material comprising of natural or artificial aggregate particles that are coated by a binder (cement) in the liquid state (fresh concrete) and cemented together permanently in the hardened condition of the binder (solid concrete). [Schor83b] (Image: Production of concrete pipes) |

|

(Image: 50 Kg Cement bag) (Image: Aggregates) Materials used in the manufacture of precast concrete pipe consist of locally available aggregates and manufactured products. Each of the materials is covered by an EN, DIN or ASTM standard relative to its properties and methods of testing. The primary components of concrete are: -

Cement

-

Fly Ash

-

Water

-

Aggregates

[FI-Lafarge] |

|

(Portland) Cement Portland cement, is a closely controlled chemical combination of calcium, silicon, aluminum, iron, and small amounts of other compounds, to which gypsum is added in the final grinding process to regulate the setting time of the concrete. Some of the raw materials used to manufacture cement are limestone, shells, and chalk or marl, combined with shale, clay, slate or blast furnace slag, silica sand, and iron ore [FI-Lafarge]. |

|

Cage machines, mandrels and wire rollers are the three most common means of fabricating reinforcing cages in concrete pipe plants. A cage machine uses reels of high-strength, cold drawn steel wire. Using adjustable guides, it positions the longitudinal wires while wrapping the circumferential wires in a helix around the longitudinal. Intersections of the circumferential and the longitudinal wires are automatically resistance welded. The process produces … |

|

Today, according to the currently valid standards for gravity systems EN 1916 and DIN V 1201, it is distinguished among concrete-, reinforced concrete and steel fibre concrete pipes. [DINEN1916:2003] [DINV1201:2004] (Image: Reinforced concrete pipes with reference to [DIN4035] - Combi-Pipe [Image: S&P GmbH]) (Image: Reinforced concrete pipes with reference to [DIN4035] - Arch profile type 2 [Image: S&P GmbH]) (Image: Reinforced concrete pipes with … |

|

The differentiation of the term with reference to the design of pipes as concrete pipes, steel fibre concrete pipes and reinforced concrete pipes is included in EN 1916: (Image: Concrete pipe) A concrete pipe is a pipe made of concrete that is not equipped with a structural steel reinforcement or a reinforcement of steel fibres [DINEN1916:2003]. (Image: Reinforced concrete pipe) A reinforced concrete pipe is a pipe made of concrete that is structurally … |

|

There are two methods of precast concrete production employed at Lafarge facilities across Western Canada; drycast and wetcast production. Dry Cast The dry cast method uses zero slump concrete and vibration to produce a dense, durable concrete. This process allows the product to be removed from the forms after the concrete has been consolidated. Concrete pipe, boxes and manhole products are manufacture with this method. Wet Cast Wet casting of concrete … |

|

The European Standard EN 1916 is valid for pipes and fittings made of concrete, steel fibre concrete and reinforced concrete and distinguishes two different types of pipes and fittings. Only pipes of type 2 comply with the German quality standard for drains and sewers. [DINEN1916:2003] Type 1 for surface water drains and sewers with a degree of resistance against attacks from the outside that complies with a “lowly aggressive” chemical environment (… |

|

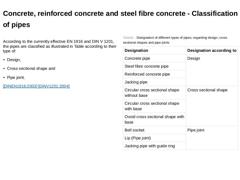

According to the currently effective EN 1916 and DIN V 1201, the pipes are classified as illustrated in Table according to their type of: [DINEN1916:2003] [DINV1201:2004] (Table: Designation of different types of pipes, regarding design, cross sectional shapes and pipe joints) |

|

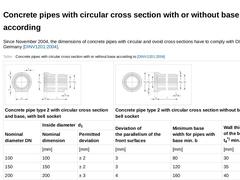

Since November 2004, the dimensions of concrete pipes with circular and ovoid cross sections have to comply with DIN V 1201 in Germany [DINV1201:2004]. (Table: Concrete pipes with circular cross section with or without base according to DIN V 1201) |

|

Where is the application of reinforced concrete pipes suitable? Reinforced concrete pipes are particularly suitable for higher loads, such as those that act due to levels of earth burial or dynamic stresses caused by heavy traffic with low depths. Furthermore, these pipes are also used for special laying conditions, as e.g. in the trenchless installation methods [Stein03]. As a matter of principle, reinforced concrete pipes with circular cross section … |