|

Aufgrund dieser Erkenntnisse empfehlen viele Autoren ( [SteinR08] [Artie1988] [Sande1994] [Bromb1993] [Grott1991] [Giesl1997] [Kraut2000] [Stotz1998] [Somme2004a] [Somme2004] [Fraen2005] [Hilli2005]) als Lösungsweg unter anderem den Ersatz der konventionellen Straßenabläufe durch Neuentwicklungen mit Reinigungsfunktionen oder mit verbessertem Feststoffrückhalt durch eine höhere Trennschärfe unter Berücksichtigung betrieblicher Belange in Form angepasster … |

|

Solche Anforderungen erfüllen die in den letzten Jahren entwickelten und in der folgenden Tabelle ohne Anspruch auf Vollständigkeit vorgestellten Spezialstraßenabläufe: Tabelle: Aufbau, Funktion und Einsatzbereiche verschiedener Systeme für den dezentralen Feststoffrückhalt nach [Somme2009] |

Aufbau |

Funktionsweise |

Einsatzbereich |

|

AQUAFOEL [FI-AquaCl] / CENTRIFOEL |

| (Bild: Dezentraler FeststoffrückhaltStraßenabläufe mit Reinigungsfunktionen oder mit … |

|

|

Tabelle: Aufbau, Funktion und Einsatzbereiche verschiedener Systeme für den dezentralen Feststoffrückhalt nach [Somme2009] (Fortsetzung) | Aufbau |

Funktionsweise |

Einsatzbereich |

| Rigo-clean [FI-Fraen] |

| (Bild: Rigo-clean [FI-Fraen]) |

Partikelreduktion vor Eintrag in unterirdische Versickerungsanlagen durch Sedimentation und Siebung sowie Leichtstoffrückhalt (Tauchrohr). Eine Kombination mit dem System Sedipipe ist möglich. |

Vorrangig für den Neubau, … |

|

|

Tabelle: Aufbau, Funktion und Einsatzbereiche verschiedener Systeme für den dezentralen Feststoffrückhalt nach [Somme2009] (Fortsetzung) | Aufbau |

Funktionsweise

|

Einsatzbereich |

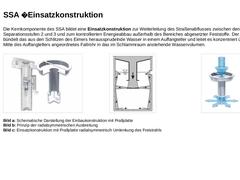

| Separations-Straßen-Ablauf (SSA) [FI-ACO] |

| (Bild: Aufbau des Separations-Straßen-Ablaufes (SSA) [FI-ACO]) |

Straßenablauf zur 3-stufigen Separation (Rost / Eimer / Schlammraum) der im Regenabfluss enthaltenen absetzbaren Feststoffe und partikulär gebundenen Schadstoffe.

Aufwirbelung … |

|

|

Tabelle: Aufbau, Funktion und Einsatzbereiche verschiedener Systeme für den dezentralen Feststoffrückhalt nach [Somme2009] (Fortsetzung) | Aufbau |

Funktionsweise |

Einsatzbereich |

| INNOLET-Filterpatrone [FI-Funke] |

| (Bild: INNOLET-Filterpatrone) |

2-stufiger Filter zur Filterung von Grobstoffen und Rückhaltung von Feinstoffen, gelösten Verbindungen und Schwermetallen.

|

Nachrüstung von neuen und bestehenden Straßenabläufen (konventionelle Straßenabläufe SB … |

|

|

Tabelle: Aufbau, Funktion und Einsatzbereiche verschiedener Systeme für den dezentralen Feststoffrückhalt nach [Somme2009] (Fortsetzung) | Aufbau |

Funktionsweise |

Einsatzbereich |

INNOLET-Rinne [FI-Sieke]

|

| (Bild: Dezentraler FeststoffrückhaltStraßenabläufe mit Reinigungsfunktionen oder mit verbessertem Feststoffrückhalt - INNOLET-Rinne [FI-Sieke]) |

Mit Substrat gefüllter Filtereinsatz für Standardentwässerungsrinnen zum Rückhalt von Feinstoffen und gelösten … |

|

|

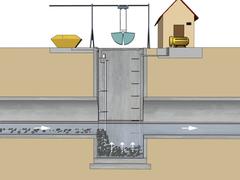

(Bild: Aufbau des Separations-Straßen-Ablaufes (SSA) [FI-ACO]) Von den in der Tabelle aufgeführten Straßenabläufen ist der SSA der einzige Straßenablauf, der speziell für den dezentralen Rückhalt absetzbarer Feststoffe entwickelt wurde, weshalb er nachfolgend ausführlich behandelt wird. Darüber hinaus ist der SSA auch zur Begrenzung akuter stofflicher Gewässerbelastungen im Sinne des BWK-M3 [BWK2004] geeignet, da er den maßgeblichen Eintragspfad für … |

|

(Bild: Aufbau des Separations-Straßen-Ablaufes (SSA) [FI-ACO]) Der Entwicklung des Separations-Straßen-Ablaufes (SSA) lag die Zielstellung zu Grunde, möglichst alle mit dem Straßenabfluss in den SSA gelangenden absetzbaren Feststoffe zurückzuhalten und Mobilisierungen der bereits im Straßenablauf abgelagerten Feststoffe auch bei Starkregenereignissen zu unterbinden [SteinR08]. Bild: Aufbau des Separations-Straßen-Ablaufes (SSA) [FI-ACO] Legende:

1. … |

|

(Video: Video Funktionsweise des ACO Separationsstrassenablauf (SSA)) |

|

Die erste Separationsstufe bildet ein verbesserter Aufsatz in Form des quadratischen Multitop 500 PF Aufsatzes für Straßenabläufe der Firma ACO Drain Passavant [FI-ACO]. Er besteht aus einem gusseisernen Rahmen und Rost nach DIN EN 124 und liegt zur Ableitung der Verkehrslast in den Baugrund und damit zur Vermeidung von Setzungen auf einem Auflagering auf. (Bild: Strassenablauf SSA - Elemente Rost) (Bild: Reinigung Straßenablauf) Bilder: Aufsatz Multitop … |

|

Die zweite Separationsstufe bildet ein im Aufsatz eingehängter Eimer der Form A4 nach DIN 4052-4. Er besitzt die gleiche Aufgabe wie der Eimer beim Straßenablauf mit Bodenauslauf, d. h. er soll in der Funktion eines Siebes durch die vorgegebenen Schlitzöffnungen Partikel > 16 mm zurückhalten. (Bild: Eimer der Form A4 nach DIN 4052-4) (Bild: Strassenablauf SSA - Elemente Eimer) Bilder: Eimer [Quelle: Prof. Dr.-Ing. Stein & Partner GmbH] links: Eimer der … |

|

Als dritte Separationsstufe dient ein Schlammraum. Alle zuvor noch nicht zurückgehaltenen absetzbaren Feststoffe sollen dort selbst bei Starkregenereignissen sedimentieren. (Bild: Separations-Straßen-Ablauf (SSA) Dritte Separationsstufe - Schematische Darstellung) (Bild: Blick in den Schlammraum [Bild S&P]) Bilder: Schlammraum [Prof. Dr.-Ing. Stein & Partner GmbH] links: Schematische Darstellung rechts: Blick in den Schlammraum |

|

Die Kernkomponente des SSA bildet eine Einsatzkonstruktion zur Weiterleitung des Straßenabflusses zwischen den Separationsstufen 2 und 3 und zum kontrollierten Energieabbau außerhalb des Bereiches abgesetzter Feststoffe. Der Einsatz bündelt das aus den Schlitzen des Eimers heraussprudelnde Wasser in einem Auffangteller und leitet es konzentriert über ein in der Mitte des Auffangtellers angeordnetes Fallrohr in das im Schlammraum anstehende Wasservolumen. |

|

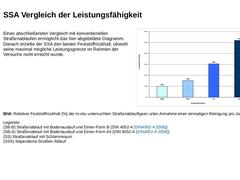

Einen abschließenden Vergleich mit konventionellen Straßenabläufen ermöglicht das hier abgebildete Diagramm. Danach erzielte der SSA den besten Feststoffrückhalt, obwohl seine maximal mögliche Leistungsgrenze im Rahmen der Versuche nicht erreicht wurde. (Bild: Relativer Feststoffrückhalt [%] der in-situ untersuchten Straßenablauftypen unter Annahme einer einmaligen Reinigung pro Jahr [SteinR08]) Bild: Relativer Feststoffrückhalt [%] der in-situ untersuchten … |

|

Herzlichen Glückwunsch! Hiermit haben Sie die vorliegende Lektion erfolgreich beendet. Im Anschluss haben Sie nun die Möglichkeit, das neu erlangte Wissen mithilfe eines interaktiven Fragebogens selbstverantwortlich zu überprüfen. Natürlich können Sie außerdem nach wie vor zu einem beliebigen Punkt in den vergangenen Lektionen zurücknavigieren, um das eine oder andere Thema oder Detail erneut anzuschauen. Bleiben Sie neugierig!

|

|

Die vorliegende Lektion behandelt die Themen semizentrale und dezentrale Sedimentation von Feststoffen. Ein Schwerpunkt bildet die dezentrale Sedimentation mit Hilfe

von Straßenabläufen. Hierbei werden die verschiedenen Ausführungsformen und Funktionsweisen dieser Bauwerke erläutert und deren Leistungsfähigkeit dargestellt. Nach Abschluss der Lektion verfügen Sie über Kenntnisse bezüglich: - konstruktiver Maßnahmen zur Vermeidung von Ablagerungen;

- Verfahrensprinzipien dieser konstruktiven Maßnahmen.

|

|

Nach [Wasserhaushaltsgesetz § 54] ist Abwasser -

das durch häuslichen, gewerblichen, landwirtschaftlichen oder sonstigen Gebrauch in seinen Eigenschaften veränderte Wasser und das bei Trockenwetter damit zusammen abfließende Wasser (Schmutzwasser) sowie

-

das von Niederschlägen aus dem Bereich von bebauten oder befestigten Flächen gesammelt abfließende Wasser (Niederschlagswasser).

(Bild: Abwasser in einem Mischwasserkanal aus Stahlbeton) Warum müssen … |

|

(Bild: Häusliches Schmutzwasser) -

Häusliches Schmutzwasser nach [EN752:2008]:

Wasser aus Küchen, Waschräumen, Waschbecken, Badezimmern, Toiletten und ähnlichen Einrichtungen.

(Bild: Industrielles (gewerbliches) Abwasser) -

Industrielles, gewerbliches Abwasser nach [EN752:2008]:

Abwasser aus Industrie- und Gewerbebetrieben

-

Fremdwasser nach [EN752:2008]:

unerwünschter Abfluss in einem Entwässerungssystem.

(Bild: Niederschlagswasser) |

|

Nach den kommunalen Ortssatzungen dürfen mit den Abwässern keine Stoffe abgeleitet werden, die den Bestand der öffentlichen Abwasseranlagen beeinträchtigen können. Einleitungsbegrenzungen existieren gemäß [DWAM115-2:2005] insbesondere für -

den pH-Wert (6,5 - 10),

-

für Sulfate (600 mg SO42-/l)

-

für schwerflüchtige lipophile Stoffe (300 mg/l) - und für die

-

Abwassertemperatur (35°C).

(Bild: Abwasser in einem gemauerten Eiprofil) |

|

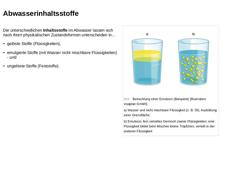

Die unterschiedlichen Inhaltsstoffe im Abwasser lassen sich nach ihren physikalischen Zustandsformen unterscheiden in... -

gelöste Stoffe (Flüssigkeiten),

-

emulgierte Stoffe (mit Wasser nicht mischbare Flüssigkeiten) - und

-

ungelöste Stoffe (Feststoffe).

(Bild: Betrachtung einer Emulsion) |

|

Ungelösten Inhaltsstoffe werden als Feststoffe bzw. partikuläre Substanzen oder Stoffe bezeichnet. Nach [DIN38409:1987] werden diese in Abfiltrierbare (AFS) und Absetzbare Stoffe (ASS) eingeteilt. |

|

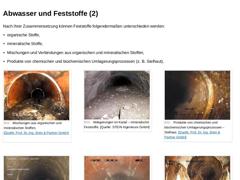

Nach ihrer Zusammensetzung können Feststoffe folgendermaßen unterschieden werden: -

organische Stoffe,

-

mineralische Stoffe,

-

Mischungen und Verbindungen aus organischen und mineralischen Stoffen,

-

Produkte von chemischen und biochemischen Umlagerungsprozessen (z. B. Sielhaut).

(Bild: Ablagerungen Abwasserkanal-Mischungen aus organischen und mineralischen Stoffen) (Bild: Ablagerungen im Kanal – mineralische Feststoffe) (Bild: Produkte von chemischen … |

|

|

|

Die eingetragenen Feststoffe in Kanalisationen stammen überwiegend aus folgenden Quellen: -

aus Schmutzwassereinleitungen

-

Feststoffeintrag durch häusliches Schmutzwasser

-

Feststoffeintrag durch betriebliches (gewerbliches und industrielles) Schmutzwasser

-

aus Regenwassereinleitungen

-

Feststoffeintrag von Bodenoberflächen durch die Straßenabläufe

-

Feststoffeintrag von Dachflächenentwässerungen

-

aus Fremdwasser

(Bild: Herkunft der Feststoffe im Mischsystem … |

|

Häusliches Schmutzwasser fällt in Küchen, Waschräumen, Waschbecken, Badezimmern, Toiletten und ähnlichen Einrichtungen an. Die darin enthaltenen Feststoffe bestehen zu 80-90 % aus organischen Feststoffen wie Nahrungsresten, Fetten, Fäkalien, Haaren, Papier etc. [Godeh2002] [ATV96] [ATVDVWKM 369:2003]. Den restlichen Anteil bilden mineralische Feststoffe, die beispielsweise aus der unsachgemäßen Entsorgung von Hausabfällen wie z. B. Katzenstreu resultieren. |